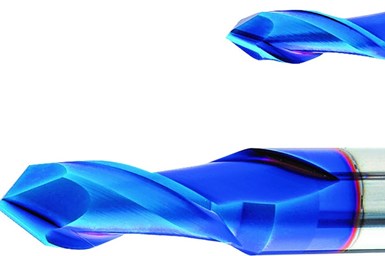

Carmex Multi-Function Milling Tool is Versatile, Durable

Carmex’s Multi-Function Milling Tool performs six milling operations on a single tool, while maintaining high performance and durability.

Carmex designed its new Multi-Function Milling Tool (MF) for a wide array of milling applications including spotting and drilling, side milling, chamfering, slotting, grooving and engraving. The company says the tool delivers versatility and superior cutting performance at a high value. The tool’s construction from an ultra-fine carbide grade enhances stability and wear resistance, while also featuring a new generation of PVD coating for higher performance.

The company says the MF Milling Tool performs multiple operations with one tool, eliminates tool changes, reduces programming and setup times and reduces tool inventories. It especially recommends the tool for machines with a limited number of tool stations.

“Carmex’s years of experience in the development of the industry’s most sophisticated high-precision tooling has resulted in a milling tool design that delivers high precision and improved finish over longer tool life,” says Jim White, national sales manager for Carmex USA. “The Six-in-One MF Milling Tool is another example of the way Carmex provides value-added solutions to our customers.”

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

-

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

.png;maxWidth=300;quality=90)