The company has introduced the DMU 160 P and DMC 160 U for five-sided/five-axis universal machining in the work area (X/Y/Z) of 63" × 49.2" × 39.4" and for workpieces of up to 8,800 lbs. The machines are said to demonstrate their value in single-part and small series production, general machine construction, tool and mold construction and the mass production sector. The machines are part of a family, in which the smaller universal machines are offered as traversing column machines, and the large machines of the 200 class are constructed in portal design. A duo block concept is incorporated in the DMU 160 P and the DMC 160 U. For this purpose, a closed (and therefore rigid) block for the incorporation of the guidance and drive elements of the X and Z axis was set up on the basis of a stable bed construction. The similarity to jig boring machines is reflected also in the high precision. According to the company, attention was given to the thermo-graphic analysis of the construction. Consequently, the main and feed drives are now also liquid cooled, just like the ballscrew spindles, which are cooled internally through the spindle. In conjunction with the linear guides, the machines thus reach accurate production tolerances, which often make the use of jig boring machines unnecessary. Unlimited five-sided machining is said to be possible in the standard configuration through the combination of vertical and horizontal milling positions of the motor spindle (12,000 rpm at 37.5-hp performance) as well as the NC roundtable. Furthermore, both machines feature accelerations of 0.7 G and 2,362 ipm rapid traverse. To make the machines fit for five-axis simultaneous machining, they come with an optional H/V head with driven B axis, 10,000-rpm maximum speed and tool fittings CAT 50 or HKS 100. The B-axis variant is also available with CAT 40 or HSK 63 tool fittings, as well as spindle speeds of 12,000 rpm and 18,000 rpm. As an alternative, it is possible to integrate a driven A axis conceived as a fork head. This axis rotates within the degree range from -30 degrees to +100 degrees and realizes machining with a negatively engaged tool. With regard to the tool magazine, the customer can adapt a completely new shelf magazine with 60, 120 or even 180 positions. As a consequence, tools with up to 25.6" length, 15.7" diameter and weights of up to 66 lbs can be easily managed. The new horizontal toolchanger achieves short chip-to-chip times of only 6 seconds with CAT 40 tools (or 7 seconds with CAT 50 tools). The tool magazine is arranged at a 90-degree angle in relation to the machine. Consequently, all the tools are located in "bite-ready" position for the horizontal toolchanger, and thus don't have to be pivoted as usual. The internal shuttle system has time, not only to supply the changer with tools, but also to individually transport tools that are no longer needed or are worn out to the eject station, and to bring a new tool to its proper place from there. For the DMC 160 U, the company has also developed a pallet changer that exchanges the machined part for a new one in the shortest possible time, because of optimized acceleration and braking performance. Finally, a pallet storage system for automated multi-shift service completes the performance and machining spectrum of these new duo block innovations.

Related Content

Digital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreBuilding a 5-Axis Cell

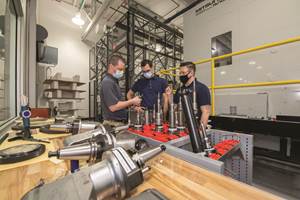

5-axis machining has taken over the metalworking industry, but what goes into a high-functioning 5-axis machining cell?

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)