Jorgensen Conveyors, Inc.

10303 North Baehr Road

Mequon, WI 53092 US

262-242-3089

jorgensenconveyors.com

IS THIS YOUR COMPANY?

Video Gallery

Magnetic Chip Conveyor - Jorgensen Conveyor and Filtration Solutions

Jorgensen engineers design a magnetic chip conveyor for a customer's ferrous metal chip application.

70th Anniversary

Jorgensen is pleased to be celebrating 70 years of innovative conveyor and filtration product design. Charles Jorgensen started ...

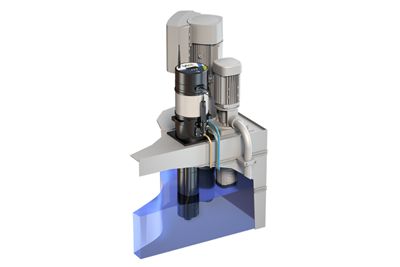

Jorgensen Conveyor and Filtration Solutions - MagDrag® Conveyor

Jorgensen's highly cost effective MagDrag® Conveyor design uses a full rail magnet, located underneath the conveyor's load and ...

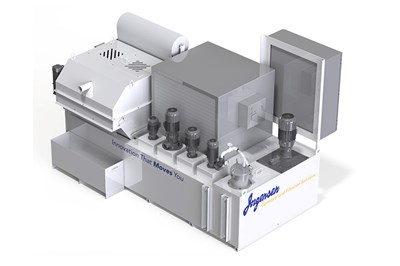

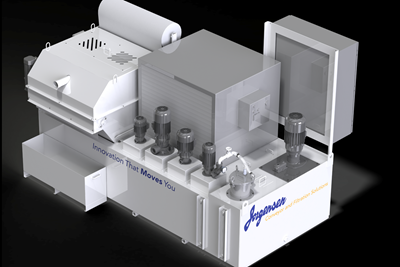

Jorgensen Conveyor and Filtration Solutions - How it Works Dual Stage Filterveyor®

The Dual Stage Filterveyor® permanent media gravity drum filtration system effectively combines chip removal and coolant ...

As Seen On Modern Machine Shop

Jorgensen Conveyors, Inc. Supplies the Following Products

Trade Names Offered by Jorgensen Conveyors, Inc.

- Convey-R-Vac

- Mag Drag

- Metalbeltveyor

- Filterveyor

- Chipveyor