Norton Abrasives, Saint-Gobain Abrasives, Inc.

PO Box 15008

One New Bond Street

Worcester, MA 01615 US

800-446-1119 | 254-918-2313

nortonabrasives.com/en-us

About Norton Abrasives, Saint-Gobain Abrasives, Inc.

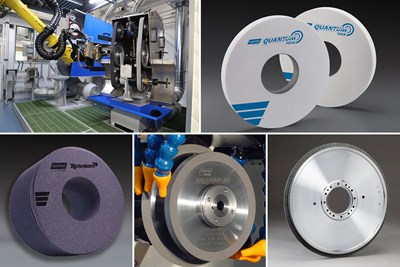

Saint-Gobain Abrasives offers powerful solutions which enable users to cut, shape and finish materials. Norton, a brand of Saint-Gobain Abrasives, has been a leader in abrasives for over 130 years offering the widest portfolio of grinding, cutting, blending, finishing and polishing solutions.

IS THIS YOUR COMPANY?

Video Gallery

Sand Larger Wood Pieces with Norton Wide Belts

Our range of wide belts are used in many large woodworking and metalworking manufacturing applications.

A Closer Look At the Grain of Norton RazorStar™

Take a deeper look at what makes the grain of Norton RazorStar™ so special. Visit https://nortonsga.us/RazorStar for more ...

Norton RazorStar™ Belts are Monsters that Eat Material!

Check out the new Norton RazorStar™ belts! Featuring a razor-sharp shaped ceramic grain, see how RazorStar is setting a new ...

Exceeding All Expectations, Norton RazorStar™ Is The New Star In Grinding!

Reach for Norton RazorStar™ quick-change and fiber discs and experience unprecedented grinding performance. For the full list ...

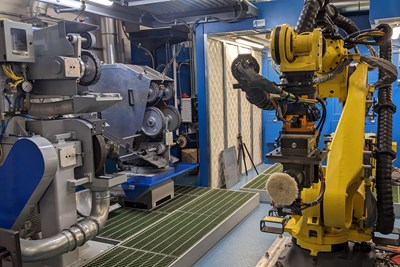

As Seen On Modern Machine Shop

Norton Abrasives, Saint-Gobain Abrasives, Inc. Supplies the Following Products

Trade Names Offered by Norton Abrasives, Saint-Gobain Abrasives, Inc.

- G-Force™

- Abrasotex™

- PowerStrip™

- Bear-Tex ®

- Plyweld®

- Rapid Strip™

- SAABA™

- DryIce®

- NorZon

- NorZon®

- PowerFlex®

- The Absolute Force™

- Quantum™

- Blaze™

- Lightning®

- Amplex®

- CloseKote®

- TwinStar™

- Universal

- Metalite®

- Onyx™

- WoodSand™

- FlexEdge™

- Durite®

- Wheel Dressing

- MultiSand™

- Silver Eagle®

- Screen-Bak®

- QuantumX™

- RapidCut™

- Black Ice®

- Charger™

- E-Z Fflex®

- NEX™

- Merit®

- MSL®

- ShurStik™

- Muscle Behind the Machine®

- Aztec®

- NorZon BlueFire®

- PaceSetter®

- FastCut™

- Speed-Lok®

- Winter®

- NORaX®

- Multi-Oilstone®

- NorGrip®

- Norton®

- PureSand®

- BlueFire™

- TufBak®

- Norton Design®

- NorZon Plus®

- Alundum®

- Torrent™

- Paradigm™

- India®

- Rescue Runner™

- Rapid Finish™

- U-Dex-It™

- Nanozyte®

- SandWet™

- RightCut™

- FlexDrum™

- PowerLock®

- NorBide®

- Norton SG Blaze®

- EZ Choice™

- Grind-O-Flex™

- RailCut™

- GreenLyte™

- Targa®

- The See-Thru System™

- Multi-Air® Plus™

- Neon™

- Furioso™

- Mini-Dex™

- Multi-Air®

- Clear Creek™

- FabCut™

- Univel®

- Gemini®

- Quadro-Fit Pro™

- NorLok™

- Global™

- JobPack™

- OpenKote®

- Vortex®

- No-Fil®

- Norton SG®

- DUO®

- AVOS®

- Speed Change™

- Crystolon®

- NorPor®

- Long Life™

- Stick & Sand®

- SoftTouch®

- Edger™

- PolyBond™

- TwinFiber™