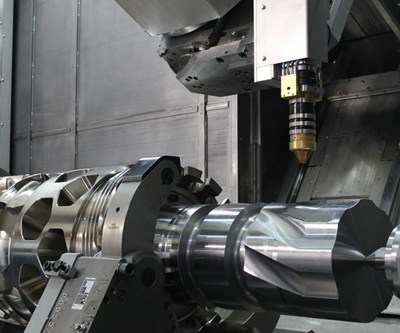

WFL Millturn Technologies, Inc. - USA

48152 West Road

Wixom, MI 48393 US

248-347-9390

wfl-usa.com

IS THIS YOUR COMPANY?

As Seen On Modern Machine Shop

WFL Millturn Technologies, Inc. - USA Supplies the Following Products

Trade Names Offered by WFL Millturn Technologies, Inc. - USA

- Millturn Technologies

- MILLTURN