Top Shops 2011: Altech Machining Inc.

Although this shop’s specialty is production CNC turning, its secondary milling, honing (or lapping) and grinding capabilities enable it to succeed in producing accurate hydraulic valve components and assemblies.

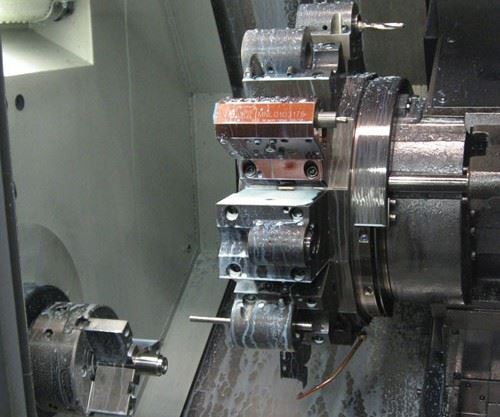

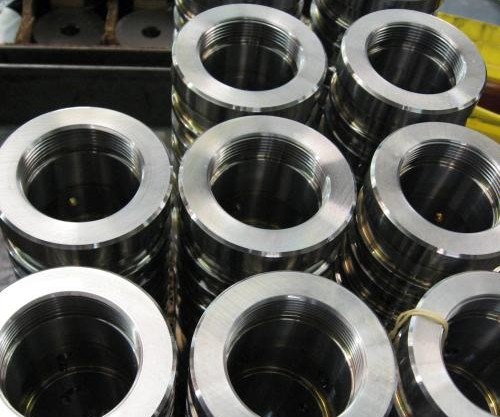

Altech Machining’s field of expertise is primarily CNC production turning, supported by secondary milling, honing (or lapping) and grinding operations. Its specialty is hydraulic valve components for the aircraft and Navy submarine applications. These valve components consist of slides, sleeves, bushings, pistons, shafts and MS and AN fittings, among others, many of which have OD tolerances of ±0.0001 and linear groove and shoulder tolerances of ±0.0005.

In addition to machining equipment, the company has inspection devices including a Brown & Sharpe CMM, Mahr Federal Digimar height gage and a Deltronic optical comparator. It also has two seats of GibbsCAM (one of which has a multitasking module); Discus AS9102 first article report generating software; Filemaker Pro database software to control production, quality, inventory and virtually all operational functions; and a kanban system for its primary customer at the customer’s facility. It performs light-duty assembly work, too.

In the video above, you can take a tour through Altech’s 6,000-square-foot facility to see the equipment and processes that are involved in manufacturing and inspecting hydraulic valve components.

Altech’s Strategies for Success

Altech Machining has come a long way from its start in its founder’s garage. Now located in a 6,000-square-foot facility, the company has 10 CNC machines—8 lathes and 2 mills—that primarily produce highly accurate hydraulic valve components. It has grown from a one-man operation to a 15-person company with annual sales of $2 million. Here are a few keys to its success:

Multifunction machines—The shop purchased its first multifunction CNC lathe—a Mori Seiki SL150SMC—approximately 9 years ago. Its newest is a Mori Seiki NL1500SMC. These lathes offer the possibility to machine parts complete or nearly complete, minimizing WIP and part handling.

Advanced cutting tools—Altech is particularly effective at producing internal features on its intricate workpieces. It takes advantage of advanced (sometimes custom) cutting tools offered by companies such as Iscar and Horn to do this.

Dedicated, informed employees—Every two weeks, managers and shopfloor employees meet to discuss the current workload, its backlog, any quality-related issues and the company’s overall status. Everyone can voice concerns or bring up issues so that they can be resolved quickly. Management feels that everyone benefits from sharing information, whether it’s good or bad, for the health and strength of its organization. This goes hand in hand with the company’s “there’s got to be a better way” mentality, which it believes is crucial to remain competitive.

Excellent customer support—Customers’ needs are taken seriously at Altech. This is demonstrated in timely deliveries, quick responses to RFQs and prompt replies to order status queries.

Key Personnel

- Alan H. Nephew, President

- Michael W. Dufford, VP/GM

- Cathy Murray, Office Manager/QA Administrator

- Dan Hopkins, Sales Manager

Products/Services

- Mori Seiki NL-1500SMC lathe

- Mori Seiki SL-150SMC lathe

- Mori Seiki CL-25 lathe

- Mori Seiki SL-15 lathe

- Mori Seiki SL-25B/500 lathe

- Mori Seiki SL-1B lathe

- Mori Seiki SL-1 lathe

- Two Mori Seiki MV junior mills

End Markets Served

- Aerospace (military)

- Aerospace (commercial)

- Hydraulic actuator manufacturers

Workpiece Materials Commonly Machined

- Aluminum

- Nitralloy 135M

- 440C

- 52100

- 4130

- 4340

- 17-4PH

- 15-5PH

- 304

- 416

Related Content

Job Shops Can’t Do Everything, And That’s OK

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

Read MoreBuilding a Better Business: Lessons for Machine Shops From an Unexpected Source

Learning how to be a great manufacturer by listening to the insights of a different industry, homebuilding (which perhaps is not so different after all).

Read MoreBusiness Award Winner Gains Traction on Strategic Vision

KLH Industries joins the 2022 Top Shops Honors Program with a renewed sense of identity, a new leadership team and new tools for driving growth.

Read MoreNiche Work If You Can Get It: A CNC Machine Shop Crafts Its Own Destiny

The latest innovations in metalworking aren’t always related to CNC automation or robotics. For Rosenberger North America, a 2022 Top Shops Honoree, it is the company’s niche processes that create the biggest successes.

Read MoreRead Next

Machining with the Environment in Mind

It’s safe to assume that most shops recognize the importance of being environmentally responsible. However, benchmarking data suggests that the effort shops put into both recycling and reducing energy consumption varies.

Read MoreSee How You Stack Up

“Top Shops” benchmarking data sheds light on what it takes to be one of the nation’s leading machining businesses.

Read MoreEach Shop’s One Big Thing

Top Shops tend to be good all around, achieving excellence or better-than-average ability in almost all of the activities or processes they perform, yet several technologies or strategies stand out as the most influential.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)