Aerospace

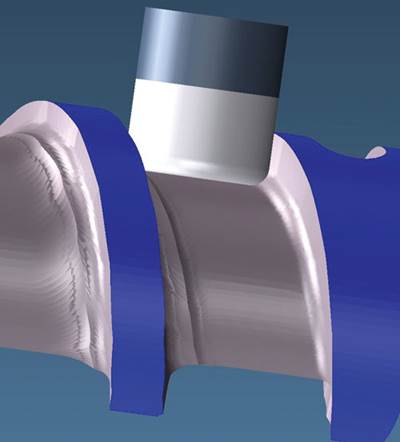

A Model Machine for Titanium

Researchers develop a machine tool that controls vibration to mill titanium more productively. The machine relies on guideway systems delivering stiffness that is literally infinite.

Read MoreMilling HRSAs: The Checklist

When milling super alloys, there are certain process requirements that must be observed.

Read MoreHow Effective is MQL for Drilling Titanium/Aluminum Stacks?

Titanium expert Mark Larson describes how coolant properties affect the cut. MQL might work, but water-based coolant is typically best in titanium.

Read MoreMaking the Most of Rotary Axes

Shops new to advanced rotary machining are sometimes held back by fundamental misunderstandings.

Read MoreMake Maximum Use of the Magazine

This shop streamlined its selection of cutting tools to machine a number of parts on a pallet system. Cutting down on cutters delivered other benefits as well.

Read MoreNesting Creates a Milling Challenge

This job shop uses remaining steel stock to hold a mated pair of aircraft parts.

Read MoreGoing Lean in Order to Grow

This shop has a plan for dramatically expanding its contract machining business in high-value markets.

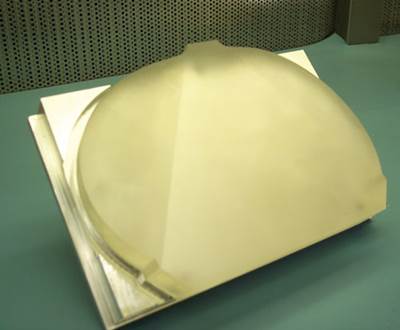

Read MoreBeyond Milling or Grinding

Ultrasonic machining opens new possibilities for NASA engineers using previously unmachinable materials.

Read MoreFive-Axis Machine Blends Power, Small Work Zone

A manufacturer of blisks and impellers needed to quickly find a new five-axis machining center, or risk losing a lucrative job. Two new VMCs fit the shop’s requirements and provided unexpected benefits. (Includes video.)

WatchDesign the Parts Around the Process

To guarantee that components for a new helicopter could be readily produced, the company looked at the capabilities of available machine tools in the market first, and then finalized the design of the components accordingly. It created a Precision Components Technology Center to embody this concept as a process for R&D prototype work. What has emerged is a flexible production model that can be duplicated at its other facilities.

Read More

.png;maxWidth=300;quality=90)