Measurement

Zeiss Holds Digital Measurement, Metrology Event

Zeiss Quality Innovation Days brings together quality and metrology experts from all over the world to take part in industry-specific sessions.

Read MoreStarrett Video System Provides Secure Measurement Data

The KMR-MX 200 Manual Video System is well suited for a range of industries such as medical, aerospace, defense and others that require traceable and secure measurement data.

Read MoreLK Metrology CMM Optimizes Measurement Cycles

Altera C HA ceramic-bridge CMMs provide volumetric accuracy from 1.3+L/350, repeatability from 0.0013 mm and scanning accuracy from 0.002 mm.

Read More4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

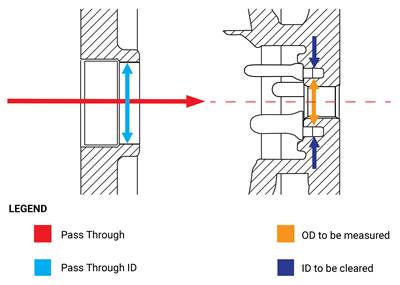

Read MoreTurning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read MoreStarrett Measurement Systems Provide Repeatable Results

The company’s optical and video-based measurement systems combine high-resolution images, intuitive software and precision mechanical platforms.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

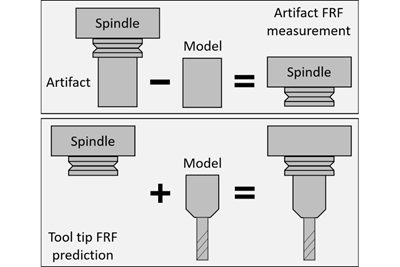

Read MoreUsing Digital Tap Testing to Measure Machining Dynamics

Tool-toolholder-spindle-machine combinations each have a unique vibration response. We can measure the response by tap testing, but we can also model it.

Read MoreMore Surface Finish Parameters at Hand

Measuring surface finish at the point of manufacture is often done by the same machinist who is manufacturing the part. They need tools that meet test requirements and are easy to use.

Read MoreNew Scale Robotics Partners With FANUC to Automate Manual Gaging

This new partnership will enable the automation of manual gaging processes, helping manufacturers eliminate bottlenecks and improve productivity.

Read More