Measurement

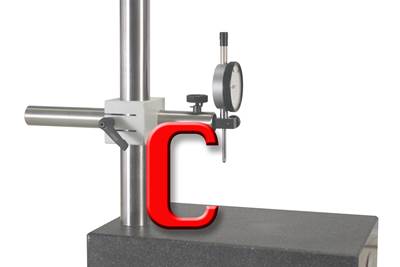

The Nuts and Bolts for Getting the Gaging Fixtures Right

Gage fixtures are the key to accurate and repeatable measurements, so make sure there is no play at its joints.

Read MoreZeiss Software Increases 3D Measurement Data Compatibility

Zeiss has launched Zeiss Inspect, a system-independent data evaluation for optical and CT measurement data.

Read MoreBYK-Gardner Gages Feature Multiple Measurement Modes

BYKO-test 9500 series of dry-film thickness gages have functions to store, archive and document measured values, easily change device settings on a PC and pre-configure by setting pass/fail limits.

Read MoreVerisurf Announces Software-Integrated CMM Sales Platform

The platforms enables customers to source new and pre-owned CMMs powered by Verisurf software.

Read MoreEvident Digital Microscope Camera Provides High-Quality Imaging

The DP75 digital microscope camera simplifies the microscopy imaging process, enabling users to concentrate more on their work.

Read MoreNikon Metrology Systems Provide Non-Destructive Inspection

The VOXLS 30 C 225, 30 C 320 and 30 C 450 models are designed for automated operations across the production sector.

Read MoreDigital Comparators are More Than Just Readout Devices

Modern digital comparators often combine the performance of touchscreen phones, LVDTs, digital amplifiers and even small PCs into the size of a standard dial indicator.

Read MoreStarrett's Wireless Electronic Depth Gage Provides Ease of Use

The new depth gages offer automated wireless measurement data collection when integrated with data acquisition applications such as Starrett DataSure 4.0 software.

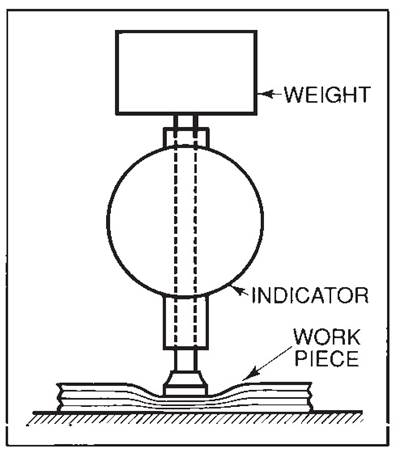

Read MoreThe Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

Read MoreHow to Evaluate Measurement Uncertainty

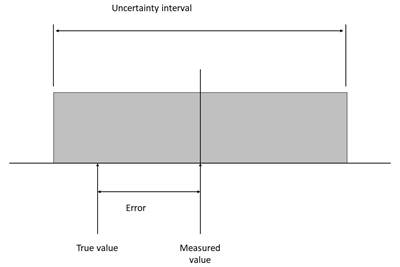

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read More