Measurement

Quality Control System Monitors, Controls Batch Production

IMTS22: ANCA showcases a range of new technologies designed to grow capacity, improve profit margins and gain efficiencies.

Read MoreProcess-Driven Measurement, Inspection Solutions

IMTS22: Verisurf’s measurement and inspection solutions include automated creation of AS9102 first article inspection reports, CMM programming and more.

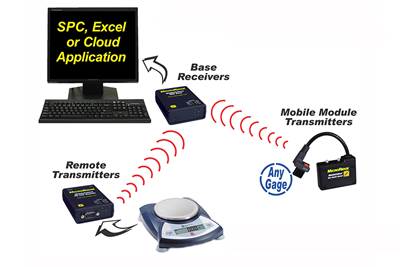

Read MoreMobileCollect Wireless for Data Integrity, Accuracy

IMTS 2022: MobileCollect system is designed to give users the greatest range of options and flexibility for configuring their wireless measurement collection.

Read MorePrecision Handheld 3D Scanner Delivers Fast Digitization for Large and Small Molds

Capture 3D is bringing the Zeiss T-Scan hawk to IMTS 2022, which can rapidly collects precision 3D measurement data in place.

Read MoreElectronic Digital Comparators Operate Reliably Anywhere

IMTS22: The Millimess 2000 W(i) and 2001 W(i) digital comparators from Mahr offer maximum measuring reliability even in harsh workshop environments.

Read MoreFive-Axis Coordinate Measuring Machines Offer Real-Time Data

AIMS Metrology showcases its full range of turnkey five-axis coordinate measuring machines. The OEM’s Revolution Series Summit 10.10.10, LM and HB are designed to provide real-time metrology which is foundational to anything that is Industry-4.0-driven.

Read MoreSensitive and Strong: Advanced Digital Comparators

Borrowing from cell phone touchscreen technology, user interfaces on industrial gages are increasingly sensitive — and strong.

Read MoreGage Management Software Optimized for Ease of Use

1factory announces the general availability of its Gage Management solution. Features include gage calibration management, gage transactions (issue/return), gage kits, gage R&R and work order traceability.

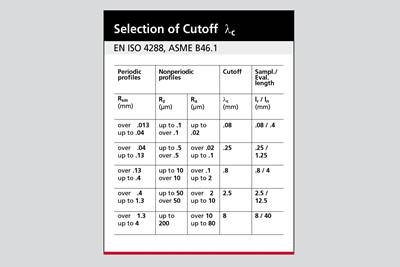

Read MoreHow to Choose the Right Cut Off When Measuring Roughness

Measurement results for surface finishing parameters can vary depending on the filter parameter (Lc), also known as the cutoff.

Read MoreHow Manufacturing Data Can Save the World

Digital spaces rooted in real-world sensor data help scale big ideas and move humanity toward a more sustainable, autonomous future.

Read More