Medical

Meeting Microgrinding Challenges

A technology for microgrinding reminiscent of Swiss-type machines' sliding headstocks can handle higher length-to-diameter ratios in the grinding of medical guidewires and other long, skinny parts.

Read MoreA Harder Surface for Stainless Steel

When it comes to hardening finished parts, the more control you have over the process, the better the results will be.

Read MoreCAM Software Provides Competitive Edge in Bringing Ideas to Life

Intriguing Concepts LLC, a mold prototyping and production shop, uses Surfcam CAM software to achieve better surface finishes and production times.

Read MoreMaking it in Medical

Here are the challenges that modern medical machine shops face and how they have helped shape this shop in particular.

Read MoreArmed for Accuracy

Portable metrology arms provide many benefits, as do standard CMMs, but how do these devices differ from each other? This company relies on both and describes the applications for which these technologies are particularly well-suited.

Read MoreMedical Shapes a Shop

Medical job and contract shops face challenges—some unique to the market they serve—that push them to become more efficient. Learn about the efforts this shop has made to clear the hurdles it has encountered along the way.

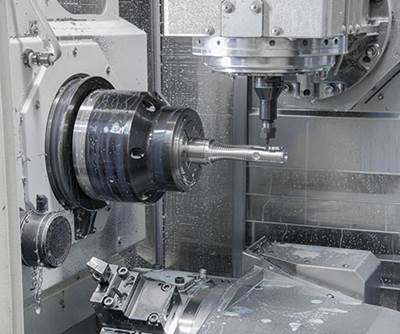

Read MoreHMC Provides Quality Needed for Medical Manufacturing

Big River Engineering and Manufacturing purchased a high-precision Makino a51 HMC to meet FDA regulations and gain customers in the medical device manufacturing industry.

Read MoreThe Big Step Up

A small shop added two new machines, each of which is more advanced than any of the previous machine tools the company has used. One of the co-owners committed to the work of bringing both of these machines fully into service. Here is the shop’s experience so far.

Read MoreShop's Success Turns on Swiss-type Technology

During the past few decades, the Swiss-type lathe has evolved from a niche product to a go-to platform for done-in-one production of small precision parts. This shop has evolved right along with it.

Read MoreAuto EDM Wire Changers Compete at the High End

Automatic EDM wire-change capability can improve efficiency and reduce costs for high-end tool and die work, especially parts with small internal radii.

Read More

.png;maxWidth=300;quality=90)