Milling Tools

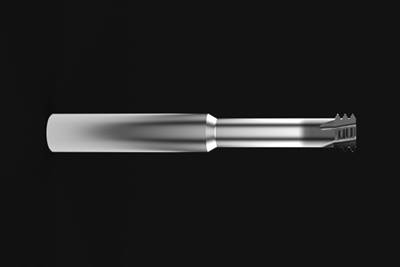

Sandvik Coromant End Mills Feature Specialized Coating

The new CoroMill Plura HD solid end mills, featuring a Zertivo 2.0 coating, are said to improve tool life, process security and productivity over previous versions.

Read MoreKennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

Read MoreOSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

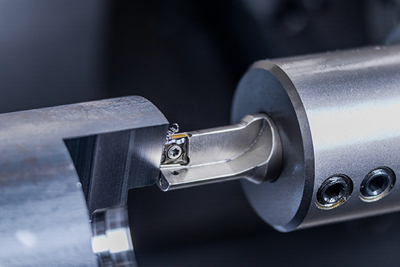

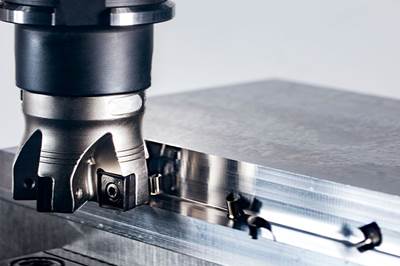

Read MoreWalter Xtra-tec XT Milling Tools Feature Pocket Design

Eastec 2023: Walter’s Xtended Technology (XT) milling tools offer large cross-sections for maximum tool stability and a larger contact surface for a secure seat and reduced surface pressure.

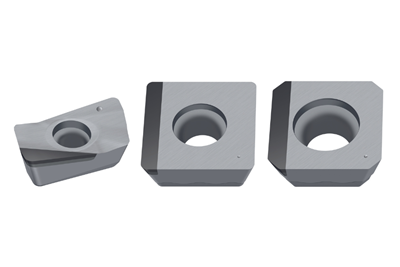

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreBig Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

Read MoreCeratizit's Control System Increases Process Security

Eastec 2023: The ToolScope monitoring and control system can reduce cycle times up to 15% and, with wear monitoring, optimize tool life and provide additional tool reserve usage up to 30%.

Read MoreAllied Machine and Engineering Offers New Sizes of Thread Milling Tools

The AccuThread T3 thread mill line is now available in larger UN and ISO sizes up to 1"-8" and M24 × 3.0.

Read MoreGreenleaf Solid Ceramic End Mills Maximize Material Removal

Eastec 2023: Xsytin-360 end mills feature a four-flute design designed to minimize cutting forces, reduce vibrations and optimize tool life.

Read MoreWalter Milling Inserts Feature PCD Cutting Edges

The PCD inserts are suitable for milling a variety of nonferrous workpiece materials, such as aluminum, aluminum-silicon alloys, magnesium, magnesium-based alloys, plastics and fiber-reinforced plastics.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)