Milling Tools

High Feed Rates or Deep Cuts - Which is Faster?

Comparing high-feed milling to other kinds, it is clear that the high feed and metal removal rates deliver on promises, but sometimes slowing down the feed and increasing the depth of cut will still end up faster.

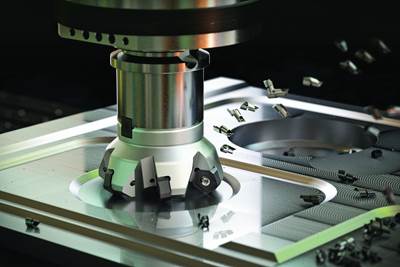

WatchTungaloy Introduces Size 12 Inserts for Cutter Bodies

According to Tungaloy, the TungForce-Rec 12 boasts 1.5 times higher tooth density than other competing shoulder milling cutters of the same size, allowing a 16 mm (5/8″) diameter cutter to carry 3 teeth and a 50 mm (2″) diameter cutter to carry 12 teeth.

Read MoreHow to Manage Cutting Tool Inventory in a Small Job Shop — The One-Person Shop #4

Working in short lead times means maintaining a large range of tools to be ready. What is the right way to stock and organize this investment?

WatchNew Indexable Milling Inserts from YG-1

Eastec 2021: YG-1’s new inserts are designed to separate each cutting edge and wiper, which result in 10 true cutting edges.

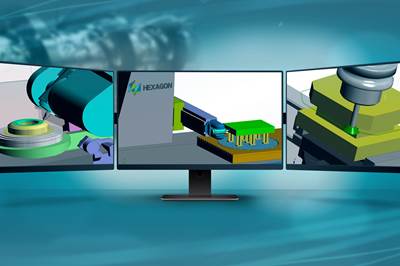

Read MoreHexagon Edgecam Now Supports Six-Axis Machining

Hexagon’s Edgecam offers dedicated six-axis tools that provide greater toolpath control and more accurate simulation of processes, reducing the need for intervention on the shop floor, improving the utilization of advanced machinery and avoiding the risk of costly damage.

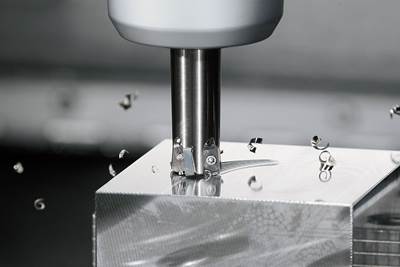

Read MoreWalter Showcases New Milling Cutters and Grooving System

Eastec 2021: Walter will showcase a new family of milling cutters and a grooving system, which provides a positive locking system and reduces indexing time by 70 percent.

Read MoreNorton Ideal-Prime Grinding Wheels Increase Wheel Life

Norton’s Ideal-Prime Internal Diameter Grinding Wheels feature optimized, proprietary grains and matrices that lengthen wheel life and improve grinding and cost efficiency.

Read MoreGWS Alumigator End Mill Reduces Roughing Chatter

GWS Tool Group’s Alumigator ASR-5 end mill sports a chatter-reducing indexing configuration and geometric features that reduce chip size.

Read MoreCNC Machining Gets a Composite Infusion

High-volume milling illuminates the potential of merging metal with lighter, vibration-resistant materials.

Read MoreBig Kaiser Expands Hydraulic Chuck Offering for Swiss Lathes

Company adds inch-sized, standard-type chucks and new F and R type chucks to its offerings for Swiss lathes.

Read More

.png;maxWidth=300;quality=90)