Turning Tools

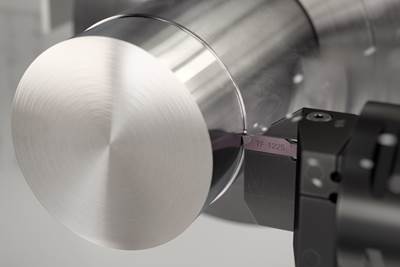

Sandvik Coromant Parting Tool Provides Improved Surface Quality

CoroCut QD Y-axis parting tools feature upgraded blades with no Y offset, providing easier programming and increased stroke.

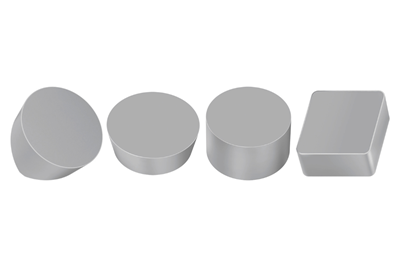

Read MoreTungaloy Modular Turning System Provides High Repeatability

The ModuMiniTurn tool system incorporates a specialized coupling mechanism between the modular head and tool shank.

Read MoreSandvik Coromant Grooving Tool Provides Stable Performance

The CoroCut 2 system features an improved clamping finger design, which offers a higher clamping force and better side stability.

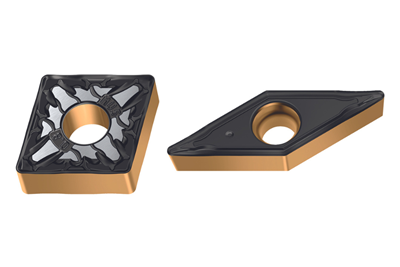

Read MoreWalter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

Read MoreWalter Turning Grades Reduce Machining Times

The WKP01G and WPP05G grades are ideal for continuous cutting and occasional interrupted cuts in high-tensile materials.

Read MoreSandvik Coromant Turning Grade Provides High-Feed Roughing

The GC4405 steel turning grade features a new carbide substrate with an optimized microstructure, which reduces plastic deformation in high-feed applications.

Read MoreAllied Machine's Threaded Lathe Sleeves Maximize Coolant Flow

The sleeves are well suited for job shops that are using aging lathes, and are designed for use on machines that do not have the capability to run through-the-turret coolant.

Read MoreTungaloy Grooving Toolholders Provide Highly Stable Machining

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

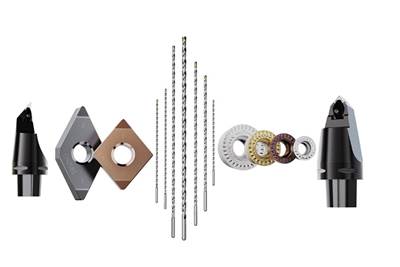

Read MoreSeco Tooling Lineup Promotes Optimized Part Processing

The company’s expanded tooling lineup is aimed at applications ranging from general ISO turning to high-volume hard turning and deep-hole drilling.

Read MoreTungaloy-NTK Swiss Turning System Provides High Repeatability

The ModuMiniTurn modular turning tool system provides exceptional repeating accuracy for the cutting point when swapping out modular heads for new inserts.

Read More

.png;maxWidth=300;quality=90)