Aberration or Accelerant: How Do You View the Past Year?

Will things snap back or will the changes last? In different areas, we might see a dramatic resumption, or we might have seen the new way coming into its own. Recent articles emphasize the different possibilities.

Aberration or accelerant. To describe the possibilities that lay just ahead, this phrasing is pretty perfect.

The words are not mine. I encountered them in a different context, an article for The Atlantic by David Sims in which he used them to wonder about the movie industry, and the ultimate effect the pandemic year will have on it. But those words, and the question they frame, actually describe just about everything: all that the pandemic has touched. For everything that changed because of the disruptions of this past year, the change may or may not be lasting. Thus, for everything disrupted, has the past year been aberration or accelerant? Will the disrupted thing bounce back, and perhaps bounce back dramatically, or will we discover the changed way is the way that was coming anyway?

I think of people working from home versus the culture of reporting to workplaces, for example. Once congregating in office buildings again becomes safe, what will we see? We might discover 2020 was an accelerant: Companies already inclined toward accommodating more flexible work arrangements and employees inclined toward pursuing these arrangements will carry their new thinking forward. Then again, we might discover 2020 to have been an aberration: The culture of workplaces exerts a pull, and people wanting to do well in those workplaces will be drawn back in. I don’t know which it will be; no one does.

Yet this same rhetorical question applies to so much more. For everything disrupted, everything changed: aberration or accelerant? The question applies to air travel, conferences, education, handshakes, meetings, public spaces, restaurants, retail, trade shows and much else. For each area that was unsettled, do things snap back or do they stay the way they have gone?

The question is subtler for manufacturers. I don’t suppose to ask the typical machine shop about its disruptions, because compared to other sorts of businesses, machine shops have continued largely as they were. They have remained staffed, albeit with distancing and other new precautions added, and they have continued making parts. However, in their case, the aberration-accelerant question applies to their customers. For each customer to a machine shop, have the disruptions of the past year changed that customer’s thinking about its sourcing? About its market? About its product lines? The independent shop has to consider these questions. And here is the interesting thing: Aberration or accelerant — for the shop, each answer points to the opposite tactic.

That is, if customers’ business disruptions this year are an aberration, then now is the time to accelerate! Things are coming back, so race ahead now to be ready when they do.

Alternately, if the disruption is an accelerant, then now is a time to hold off. Wait, keep your options open, and watch to see what the form will be of the world that is coming next.

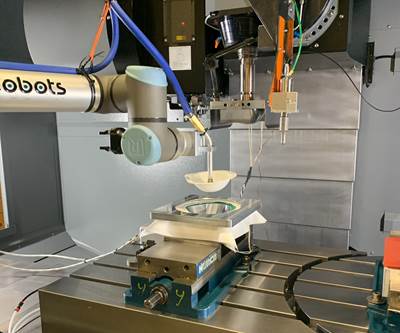

Among articles we’ve posted recently are two pairs emphasizing the two different views. For a sense of the world to come, the world that it might turn out the disruptions have helped to bring more quickly, here are two pieces about additive manufacturing, and how machining and 3D printing increasingly interrelate. The move to additive was already happening, so if disruptions accelerate movement already underway, then watch for this as the direction of the surge. Read about a machine tool designed for the needs of AM and, in a far more speculative case, read about how 3D printing is being offered as a potential aid for quickly expanding America’s capacity to make machine tools.

B.I.C. Precision Machine Co. had been using CAM software for years, but the company made the shift during the pandemic to fully implementing CAM as an alternative to on-machine programming. The shop is more ready than ever to serve customers as business returns.

But complementing these glimpses are two views of machines shops racing ahead — taking advantage of a lull in one case and an increase in work in the other to implement capabilities that will make the shop even more prepared when business as usual resumes. One job shop adept at on-machine programming makes the move all the way to CAM, while a shop using vertical machining centers learns to succeed with its first horizontal.

We are perhaps four months away, or maybe it is more like ten months away, from coming out the other side of this period — looking back on the pandemic and beginning to learn what it was and what impact it had.

Aberration or accelerant? Think of it: By the time we reach the end of this calendar year, in every different area that has been disrupted, likely we will get to see which of these two roles the pandemic year played.

Read Next

Hope Is an Asset: Here Are Machine Shops Following Clear Visions for the Future

A simple strategy offering a clear aim to hope for is particularly valuable during a disruptive time. Recently posted articles offer examples of shops following clear ideas for the way ahead.

Read MoreVideo: Hurco Machining Center Adapted Into N95 Mask Production System

CNC machines can do more than we think. They are automation platforms for insourcing.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)