Accuracy Achieved By Milling On A Magnet

Trilogy Systems ran into a major manufacturing hurdle as the length of its motors increased. The linear motor body comprises a U-section made up of three precision-machined mild-steel plates into which the magnets and coil assembly for the motor are installed.

Trilogy Systems, a leading manufacturer of high accuracy linear motors used for positioning tables in the semi-conductor industry, ran into a major manufacturing hurdle as the length of its motors increased. The linear motor body comprises a U-section made up of three precision-machined mild-steel plates into which the magnets and coil assembly for the motor are installed. As motors became longer over the years, it became increasingly difficult to maintain accuracy using vises to fixture the steel plates. And with the acquisition of a new mill with the capability to machine motor bodies up to 120 inches in length, it became clear that the battle of fixturing in vises had been lost.

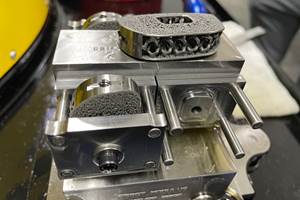

Bruce Beakly, President of Trilogy and chief engineer of the Trilogy linear motors, was aware of the holding power available from magnetic systems and turned to WEN Technology for assistance with a magnetic workholding system for his milling requirements. The solution chosen was a set of Bakker permanent magnetic chucks. Since the parts to be held were thin, it was imperative that a fine pole distribution be used so that the magnetic energy would be held within the part and not cause chip retention problems—which could cause damage to the milling cutters—or reduced holding power. For the linear motor bodies which have a finished thickness of approximately 0.25 inch, the Bakker Standard Pole series of permanent magnetic chucks provided the best combination of features: magnetic energy is held within the workpiece, a holding force of 116 psi is achieved, and thermal stability is maintained.

The choice of permanent magnet chucks for such a large milling table—12 by 120 inches—versus electro-magnetic chucks might at first appear rather unusual. However, the fine pole distribution, full magnetic saturation, ease of installation, reliability and thermal stability of the permanent magnet design proved to be clear deciding factors.

Another factor in machining the motor body components was to be able to machine the parts complete in one setup. In particular, it was necessary to mill both ends, all details on one face and drill through for assembly fastener access. Again, the magnetic solution proved highly versatile with a laminated wear plate used to support the part. Through drilling is accomplished by drilling into this disposable plate thus minimizing setups and helping to maintain accuracy.

"In the old days, we were quite good at setting up 24-inch motor plates in vises," said Production Manager Larry Floro. "But when it came time to set up 120 by 2 by 0.25 inch motor frame plates in vises, there was just no way. If we got it straight, it wasn't flat. If we got it flat, it wasn't straight. And if we could get it straight and flat, it wouldn't stay that way during machining.

"With the magnets, I have a disposable face plate which has been qualified to the machine," said Production Manager Larry Floro. "We can lay the plates down in sets, turn on the magnet and cut. Net result is a set of motor plates that are matched and within our manufacturing tolerances every time Any style, any size: just lay the plate down, load the program and cut."

For Trilogy Systems, the answer to reduced setup time and improved accuracy has proven to be magnetic chucks on their mills.

Related Content

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More