Adopting a 24/7 Mindset

This shop considered a number of factors before establishing an effective process to run an HMC cell around the clock for applications in aerospace, oilfield and other industries.

Soon after starting R&G Precision Machining in 2004 with partner Ronald Gladnick Jr., company President Paul Ryan determined that an HMC would be more effective in producing families of parts than the shop’s existing VMC.

R&G, originally located in its lone customer’s Southern California facility, used its VMC to machine parts that it subsequently assembled into the customer’s helicopter accessory products. These products required multiple part numbers, and assembly couldn’t begin until all components were available. Therefore, the shop had to set up and tear down numerous small-batch jobs on the VMC until it had enough components to start product assembly.

Mr. Ryan had experience with HMCs working for an aerospace shop prior to starting R&G, so in 2005, he purchased a stand-alone, 60-tool HMC with a pallet changer. The four-axis horizontal could machine three sides of part at a time using a tombstone, minimizing setups. It also enabled the shop to fixture multiple part numbers on one tombstone, while its larger tool capacity—three times that of the VMC—meant tools for various jobs and/or redundant tools for long-running jobs could remain installed in the machine’s toolchanger magazine.

The HMC’s versatility and improved throughput reduced the lead time for the helicopter products by 40 percent. Plus, the added capacity prompted the shop to pursue additional customers in aerospace, oilfield, firearms and other industries. However, Mr. Ryan admits that his shop wasn’t as proactive as it could have been at prepping and staging work for the HMC, which caused the machine to sit idle during setups more that it should have. In addition, the machine wasn’t realizing every bit of potential production time available in a day with just the two pallets. Eventually, Mr. Ryan began to consider an HMC with a multi-level pallet rack, which would enable numerous pallets to be set up and placed in a queue for automatic delivery to the HMC when the production schedule called for them. The machine also could run around the clock, tended by a single operator or on its own, maximizing spindle utilization time.

R&G’s HMC cell was installed in September 2012 at the shop’s current facility in Oceanside, California. Things were looking up until, very soon after the cell’s installation, the shop’s biggest customer unexpectedly reduced its work by 40 percent. Since then, though, R&G, now with ISO 9001:2008 and AS 9100 certifications, has hustled to add additional customers and solicit new work from existing ones. Mr. Ryan has also recently started a precision weapons business, Shield Defense, and machining work for that product line flows through the cell, too.

R&G continues these growth efforts today, leveraging the 24/7 production process it has developed over the years as well as the faster cycle times the new HMC offers, resulting in faster deliveries to customers. Mr. Ryan and Dax Harrison, the shop’s sales engineer, explained during a recent visit to their San Diego-area facility how adopting a 24/7 approach to parts production has impacted the shop.

New Machine, New Approach

Mr. Ryan moved R&G out of its first customer’s building to its current facility in 2011, because the growing operation needed the additional space. Today, the shop has seven CNC machine tools and turning centers installed around the perimeter of the HMC cell that is located in the middle of the shop floor.

When the shop began looking into HMCs with pallet racks, a variety of suppliers were considered. Ultimately, R&G chose a modular 18-pallet Makino MMC2 production cell using the machine tool builder’s a61nx HMC. Mr. Ryan says a number of factors played into the shop’s decision to go with an MMC2. He points to Makino’s good reputation in the aerospace industry and appreciates the speedy service it provides. The latter is important, he notes, especially because the cell has just one machine. If that were to be offline, the entire cell would sit idle.

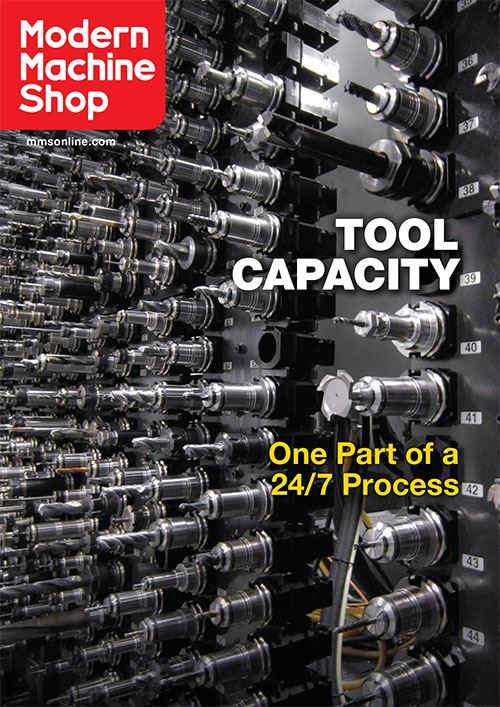

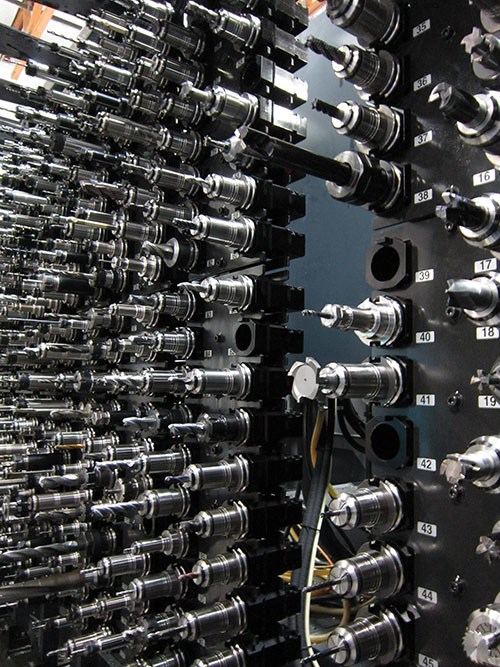

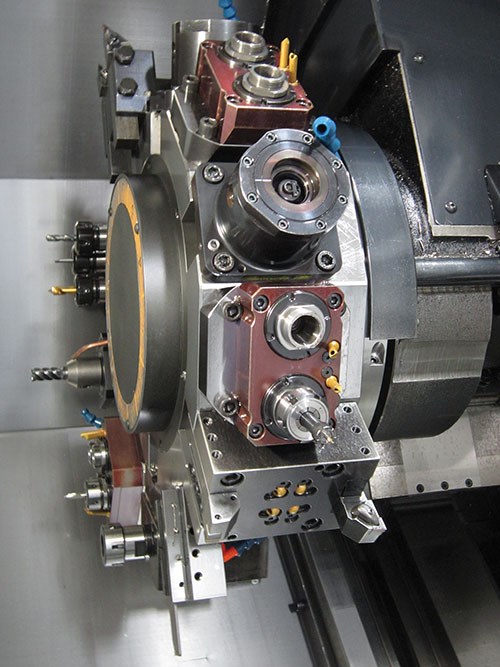

The four-axis a61nx is a 40-taper horizontal with a 19.7 × 19.7-inch table and 14,000-rpm spindle providing 240 Nm of torque. It also has ample tooling capacity. When Mr. Ryan purchased the original stand-alone HMC, he thought its 60-tool capacity would be more than sufficient to accommodate a wide range of jobs. In hindsight, he wishes he would have gotten more tooling capacity with that machine. That’s why there was no skimping when it came to the a61nx. It has a 313-station ATC magazine, which is the largest available with this machine.

Having this tool capacity facilitates faster setups. While some tools are redundant for long-running jobs, the majority are varied for different jobs. At any one time, the machine could have enough tools to run 25 different jobs. This is a great time-saver, because when a job returns, there’s no need to have a person re-measuring and installing tools in the machine. Mr. Ryan estimates that eliminating this step cuts setup times in half.

The cell’s HMC is primarily used to machine aluminum parts, benefiting from a Chipblaster variable high-pressure coolant delivery system. However, Mr. Ryan notes that it has ample rigidity and power to effectively machine the increasing amount of steel and stainless steel work R&G is winning for applications such as oilfield drill bit casings.

To facilitate unattended operation, the machine features a broken tool detector in the tool magazine as well as a Blum laser tool probe. The laser probe can detect chipped tools and perform in-process length and diameter measurement, automatically updating the CNC as tools wear. In addition, the machine has a Blum touch-trigger probe, which is helpful for locating castings fixtured on the machine or to ensure that parts are re-fixtured accurately prior to subsequent operations.

Feeding the Machine

Aside from the HMC, pallet rack design was another factor in the decision to go with the MMC2, Mr. Harrison notes. Some equipment manufacturers offer two-level systems in banks of six pallets. As floor space was a premium in R&G’s 8,700-square-foot shop, it made more sense to opt for a three-level system available with the MMC2. This enables 18 pallets to fit in the same amount of floor space that a traditional two-level, 12-pallet system would require.

The pallet rack has two loading stations and a servo-controlled rail-guided vehicle that transports pallets to and from the machine. R&G creates its own fixture plates and tombstones. When assemblies have matching right- and left-handed components, the shop commonly designs a tombstone to hold those mirrored parts on opposite sides of the tombstone. In other instances, it fits as many components as possible on whatever fixturing device is appropriate.

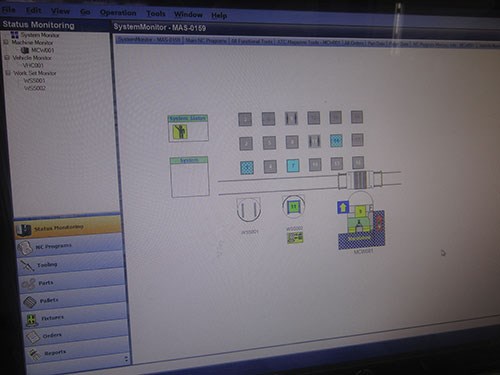

The Makino Advanced System-A5 (MAS-A5) cell control software monitors and controls the production process by automatically assigning work and initiating operations based on machine and material availability. Its intuitive, interactive graphical interface provides the status of equipment, processes and tools at a glance. The shop enters job information including batch size, delivery date and priority number, and the software then considers delivery date and priority to determine job order. It also tracks tool life, providing an alert when a tool requires change-out based on a pre-determined maximum cut time or total number of parts machined. The software can also set a schedule as to when operators are on duty or off duty, enabling the machine to run unattended and make automated decisions even in the event of tool alarm conditions. It can be accessed remotely via computer or smartphone, which is handy if, for instance, a customer calls during off hours to request an earlier delivery date and the job schedule must be changed.

Mr. Ryan says the software can create just about any report he might want, too, such as A5 reporting for production data, tool data, production results, alarm history and utilization. This data can be exported and stored offline in multiple file formats.

Cutter Considerations

The shop has always used advanced cutting tools to get the best performance from its machines, Mr. Ryan says. It has standardized on the Powrgrip toolholding system from Rego-Fix for the cell’s HMC and its other machining centers. This system consists of precision, collet-style toolholders and a benchtop hydraulic press used to insert or remove collets from the holders. These toolholders are balanced to 25,000 rpm, offering TIR of 0.00012 inch and 1,100 Nm of clamping force. According to Mr. Ryan, this toolholding system enables quicker, safer tool changes than shrink-fit systems.

Once tools are installed in their toolholders, tool measurement is performed on a Zoller Smile 400 presetter using Zoller’s Pilot 3.0 software that presents users with a selection of more than 200 automatic cutter shapes from which to choose. It also communicates directly with the cell’s MAS A5 controller. Measured tool presets can be uploaded to the MAS A5 and then to the machining center automatically.

This equipment is found in a tidy area behind the cell’s pallet racks, which represents a big change for the shop in terms of kitting jobs for both the cell and its stand-alone machining centers. In addition to the presetter and benchtop toolholder press, this area includes raw material racks, a saw to cut workpiece blanks and job carts. Setup personnel can load a cart with the tooling, raw material and job traveler for upcoming jobs. This proactive job kitting can save hours of potential machine downtime that would be lost if preparation for a new job was put off until a current job is completed.

Results

Because the shop’s workload changed drastically at the time the cell was installed, it is challenging to determine precisely how the cell has boosted production. However, Mr. Harrison says the a61nx has cut cycle times for some parts by 50 percent, with some operations now running as fast as 500 to 600 ipm. This, combined with a 24/7 production schedule, enables assemblies that previously required 6 weeks for a batch of 20 to be completed in 4 weeks. The shop also is adding more deburring operations to its machining cycles. Although this adds to a part’s total cycle time, features such as chamfers have a more consistent finish than if they were added by hand. This also frees shop personnel to perform other duties.

In addition, the machine’s speed and the automated nature of 24/7 production has the shop looking at scheduling more closely these days while actively staying on top of material purchases for upcoming jobs. Mr. Ryan says a second a61nx machine and additional pallet pool capacity will be added when the timing is right. In fact, the concrete pad for the second addition of pallet racks was poured when the cell was installed. The expansion should be a streamlined effort because the MMC2 is based on a modular design platform. R&G is also looking to bolster its turning capability by adding a twin-turret machine, which, like the HMC cell, will be another first for the growing shop.

Related Content

The Job Shop Is the First Half of the Business

By day, NTL Industries went from a lathe and a mill in a home garage to an 11-employee enterprise in under five years. By night, it tackles a new future.

Read MoreShop Replaces Two Verticals With One Horizontal

By trading two VMCs in to help finance the purchase of a new HMC, this shop was able to significantly increase production and move to lights-out machining.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)