ESSENTIAL READING

VIEW ALLMission Critical: An AM Breakthrough in Commercial Aviation

The GE9X is the first commercial aircraft engine to reach production with significant additive content. The story of GE’s accomplishment and why it matters.

Read MoreVideo: Safety Is No. 1 in Metal AM

John Murray of Concept Laser discusses safety, quality and automation as they relate to additive manufacturing for production metal parts.

WatchSlideshow: Inside the New Honeywell AM Facility for Reactive Metals

Seven machines currently committed to aluminum expand the company’s capacity to 3D print both tooling and parts. One of the photos illustrates a safety measure addressing reactive metals.

Read MoreVideo: Step by Step AM for Aerospace

A short video from Pratt & Whitney outlines the steps necessary to take a metal AM part from design to installation.

WatchHear UL’s Recorded Webinar about Training and Certification in Additive Manufacturing

Personnel development will be an important prerequisite for the advance of AM. Christopher Krampitz discusses the skills and knowledge necessary in this webinar.

Read MoreVideo: The Additive Nozzle’s Origin Story

The LEAP engine fuel nozzle is likely additive’s greatest success in part production so far, but it wasn’t always clear that the nozzle could be made this way. This video from GE Aviation tells the story.

WatchLatest Aerospace News And Updates

America Makes Names Winners of EARTH Project Totaling $1.2 Million

Recipients of America Makes’ EARTH project awards will explore sustainable approaches for reusing and recycling additive manufacturing materials and designs. Their initiatives are expected to make substantial contributions to reducing waste, conserving energy and mitigating carbon emissions

Read MoreAmerica Makes Announces Winners of Open Project Call Totaling $1.2 Million

The open project call topics were initiated at the America Makes’ Additive Manufacturing Technology Roadmap workshops in 2021 and 2022.

Read MoreValiant Products Buys Velo3D Sapphire XC to Produce Mission-Critical Parts

Valiant Products purchased a Velo3D Sapphire XC large-format 3D metal printer which is calibrated for high-temperature, high-performance Inconel 718 alloy.

Read MoreMT Aerospace Expands Services With AddUp PBF Technology

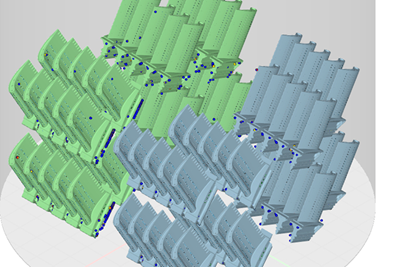

MT Aerospace says its FormUp 350 machines have proven their ability to produce highly complex parts, such as heat exchangers, with an unrivalled surface finish.

Read MoreGKN Aerospace Invests £50 Million to Grow Sustainable Additive Fabrication Capability

The investment will establish a Center of Excellence in Trollhättan, Sweden, which the company will use to accelerate and scale up production of the groundbreaking technology.

Read MoreAmerica Makes Announces Winners for IMPACT Project Call

The project call focuses on additive manufacturing research related to casting and forging, metal powder sourcing and robotic AM process planning for continuous fiber-reinforced composite structures.

Read MoreFeatured Posts

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More7 Lessons From General Atomics on AM for Aircraft Part Production

A manufacturing leader overseeing the way additive manufacturing is transforming unmanned aerial systems (UASs) offers observations about succeeding with 3D printing as an aircraft production process.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreFeatured Media

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

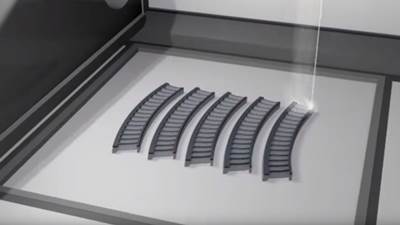

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

WatchThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Watch3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

WatchFAQ: Aerospace

Why is additive manufacturing an ideal option for aerospace training devices?

High-fidelity trainers need to be as close to the actual aircraft as possible, so they’re often made using salvaged aircraft parts. There is currently a low useable inventory of salvaged parts. These are low-volume, one-off parts, which is a strength of additive manufacturing. Read more here.

How can additive manufacturing benefit space exploration?

Because additive manufacturing is continuously progressing in material adoption and end-use application, its benefits to almost every industry, including space exploration, are potentially endless. Here are two examples:

AM can assist with getting vehicles to space by providing weight reduction and improved performance to complex parts such as thrusters and engines.

Printing spare parts in space is another benefit, alleviating supply chain and inventory challenges.

Click here for more benefits and to see a part that was 3D printed on the International Space Station.

What are examples of AM impacting the aerospace supply chain?

- An airline used 3D printed molds to cast covers for aircraft engines while the planes were docked during the height of the Covid pandemic and engine covers were difficult to source.

- Metal AM is used to provide fast turnaround, customization and complexity to aircraft repair parts, including integrally built rotors or “blisks.”