Attacking Unplanned Machine Tool Downtime with Predictive Maintenance

Sponsored ContentA new predictive maintenance application on Makino machining centers identifies issues before they turn into production problems. It also helps optimize machining processes and increase equipment utilization.

Share

Read Next

Maybe you don’t think much about it when a machine is new. But over time, a machining center is going to require more than routine maintenance. Sooner or later mechanical components are going to wear, alter machine performance and may even lead to catastrophic failure. The questions to ask now are: When is that most likely to happen? How disruptive will unplanned maintenance be to your production schedule? And how much will it cost you in substantial repairs and lost production?

What if a machining center could monitor itself and predict impending problems before they occur? Now that could cut out preventable production interruptions and enable shops to perform maintenance at the most convenient times.

Much has been made of the potential of IIoT technology to address “predictive maintenance” and a host of other issues sometime in the future. But what can the industrial internet of things or Industry 4.0 do for manufacturers right now?

Makino has a very practical answer for that with its MHmax machine health monitoring system. By applying sensors and proprietary predictive analysis algorithms that constantly check the health of a machining center’s spindle, toolchanger, coolant and hydraulic systems, machine-resident software can detect when critical systems are trending toward the need for repair. This isn’t technology coming somewhere down the road. It’s available on selected Makino 1-series horizontal machining centers today.

View Mhmax machine monitoring video.

Out-of-the-Box Diagnostics

Manufacturers have been using sensors to measure data points like sound, heat and vibration on machine tools for years, but making the best use of the data has not been easy. External monitoring systems had the ability to compare sensor data to a known set of baseline conditions but still required continued technical development to be effective. What’s different with MHmax, which stands for Makino Health Maximizer, is that a fully functional monitoring and analysis system resides entirely in the machine control.

Sophisticated machine learning software paired with a sensor array works from day one and adapts to machine characteristics as it monitors performance over time. This is what enables the system to predict component failures before they happen. With a constant stream of sensor data to analyze, the system “learns” which machine characteristics are normal and which are not. And it can determine early on when machine characteristics are beginning to trend toward a non-conforming condition.

An interesting aspect of MHmax is how it originated. You can try to monitor virtually any component on a machine tool, but going overboard adds needless complexity and costs that may not really add value. Makino wanted to develop a cost-effective predictive solution that solves the most common real-world problems. So they began by analyzing their own service dispatch records to determine systems posed the highest probability of causing unplanned downtime should they fail. According to Makino’s Dan Wissemeier, IoT customer support engineer, “It’s not necessary, for example, to measure ballscrews. They are so reliable that it wouldn’t be cost effective.” On the other hand, “A production machining center can have two million tool changes per year. Sooner or later, that’s going to need maintenance,” he says.

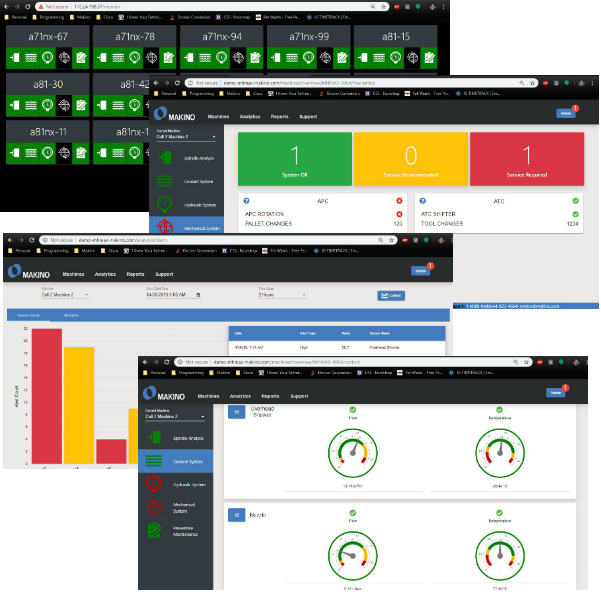

MHmax provides actionable insights into the status of critical machine tool systems. Shown here are all machines overview (top), mechanical systems status (2nd), machine alarms history (3rd), and coolant pressure and temperature (bottom).

In all, the MHmax system includes multiple embedded sensors collecting data at the most critical points in a machine. Using this data the predictive software checks for spindle health, analyzes controller data and calculates the needs for alerts or warnings on critical machine functions. It checks spindle vibration, load and speed; automatic toolchanger alignment; coolant flow and temperature; and the hydraulic system pressure and temperature. A 24/7 alert system pushes notifications via email or text to designated recipients.

In addition to the predictive maintenance aspects of MHmax, it also provides a real-time portrait of a machine’s status, which can be enormously helpful in optimizing processes, improving equipment utilization and enabling more worry-free hours of unattended or lightly tended machining.

Monitoring data can be viewed on Makino’s Pro 6 HMI display, or remotely via a network connection, depending on the user’s preferred level of system connectivity. Daily, weekly and monthly uptime and predictive reports are available, and frequencies are selectable.

It’s Your Data

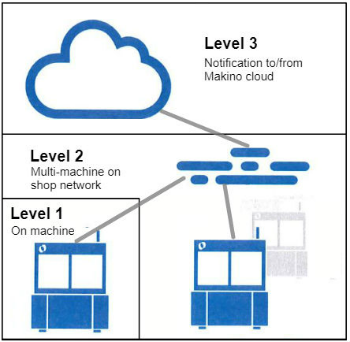

Most IIoT systems today rely on uploading sensor data to cloud-based application. Data is frequently pooled with other users allowing the vendor to mine data in ways that are not necessarily shared with the customer. MHmax is distinctly different from this approach because most of the data processing and analysis happen right at the machine tool and are shared in a way in which the user has total control. There are three levels of system connectivity:

In Level 1, the entire application runs in a standalone mode and is viewable only on the machine Pro6 control screen.

With Level 2, multiple machines can be connected to a company network. A common dashboard displays all connected machines and can be accessed by desktop computer or mobile devices.

Level 3 provides a direct link to Makino’s service management system. While the data remains secure inside the shop’s network, individual machine alerts are pushed out so Makino can keep a machine history for the customer. With this level of support, highly trained service technicians can contact customers in a proactive fashion.

It’s Just the Beginning for Machine Monitoring

Initially, Makino is offering MHmax as an option on selected horizontal machining centers and has future plans to apply it on all production-oriented equipment. Also, a retrofittable kit is in the works. The software is continually in development and moving toward “prescriptive maintenance” where the system identifies possible causes of non-conforming conditions.

What’s the value of having predictive maintenance on your next production machining center? For a moment, don’t look forward but instead, look back. What has your service history been, and what did unplanned equipment failures impact? What did they cost, not just the repairs, but the lost production? That may not be top of the mind for the machine you are buying today, but it will be. It’s just a matter of time.

Go here for more information on Makino’s MHmax.