Automatic Tool Dispenser Controls Tools But Builds Trust

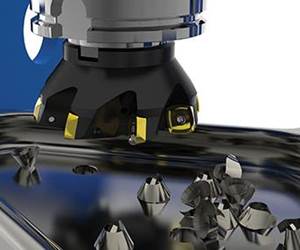

Automatic dispensing device to distribute carbide inserts and diamond tools for dressing grinding wheels. A new level of control over the available supply of cutting tools.

Conventional wisdom might consider the terms control and freedom to be mutually exclusive--you can't have both at the same time. That's not the case at a bearing plant in Indiana, when it comes to using an automatic dispensing device to distribute carbide inserts and diamond tools for dressing grinding wheels. The automatic tool dispenser (ATD) in place at the Federal-Mogul bearings plant in Greensburg, Indiana, gives management a new level of control over the available supply of cutting tools. At the same time, machine operators in the plant enjoy new levels of access to the cutting tools they need to do a job.

At some plants, worries about the availability of essential cutting tools and tooling items have encouraged machine operators to hoard certain items in anticipation of shortages that might otherwise disrupt production. But squirreling away end mills and inserts in tool chests by the machine makes it difficult for tool crib attendants to monitor supplies and restock promptly and appropriately. The result is usually a pattern of overstocking and understocking. Tooling costs inevitably go up while machines sit idle for lack of the right tool. Typically, the response has been to further restrict access to tools and increase usage monitoring and even surveillance. Tool cribs end up looking like fortified bunkers with everything but barb wire and German shepherd dogs.

"That's hardly an atmosphere that builds trust," comments Dan Schwendenmann, Purchasing Manager, at the Federal Mogul plant. "We'd rather our people honor our intentions to make sure they always have the right tools to do the job just as we honor their intentions to use the tools in the most effective manner." A few years ago, the plant looked for new ways to implement this approach.

One of the most successful innovations has been the installation of an ATD manufactured by Vertex Technologies, Inc. (Cincinnati, Ohio). This dispenser looks and works somewhat like a vending machine but is engineered for much more highly reliable operation. The benefits of automatic tool dispensing have been, according to Mr. Schwendenmann, a decrease in tooling costs and virtual elimination of tooling outages that effect production.

The ATD is located next to an aisle across from a bank of multi-spindle automatics and other machine tools. To get needed tools, an operator swipes an identification card through the magnetic reader and types in the tool code with a keypad on the front of the unit. The code corresponds with items listed on a chart posted right on the unit. The list gives the location of the tool inside the ATD, a product code or description, the company's own part number, and a sample item glued or taped to the chart. Operators can choose the right tool by matching up items from a tool list or process sheet, or recognize it by sight from the samples. About 55 or 60 different items are dispensed by the ATD, roughly 90 percent of which are various grades and styles of indexable carbide inserts.

After the selection is entered, the item drops to the retrieval bin or can be taken from a tray accessed through a door on the auxiliary unit beside the main unit. Information about this transaction is recorded and processed by computer.

"What we don't do is use this system to spy on our employees," Mr. Schwendenmann stresses. "Our policy is to ensure that operators are free to take what they need." The system is capable of automatically comparing tool usage by job or employee against usage standards but this installation is not set up for this. "Some items are programmed so that the employee gets notice of excessive usage, but we leave it up to the individual to see a supervisor to check on any problems this might indicate."

What the computer does do is keep track of all items taken out so that the tool crib can print a report of supply levels, with items below the preset restocking limit flagged. The crib can create pick lists for restocking the ATD, and if restocking creates a reorder situation, another report summarizes these by vendor. The required quantity is then reordered from the vendor by fax. The system also allows outside vendors to do on-line monitoring themselves at a remote site, an arrangement the Federal-Mogul plant will continue and expand if additional ATDs are installed in the future.

All items in the ATD are on consignment. "We pay for the tool only after it hits the retrieval bin," says Mr. Schwendenmann. The savings in tooling expenditures that would otherwise have been used to build inventory are sufficient to more than cover the lease on the ATD, he says. Tooling vendors have been happy to go along with this arrangement. It smooths out their delivery schedules and avoids emergency orders that must be expedited.

"Everybody wins." Mr. Schwendenmann explains. "Best of all, operators can trust us to have the tools ready when they need them and we can trust them to get the job done."

Related Content

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)