Boosting Productivity For Turbine Engine Part Makers

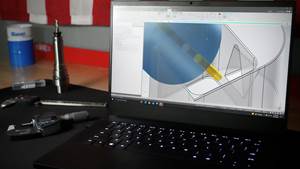

Compared with common steel, the heat-resistant super alloys (HRSAs) and other hard metals used in jet engines and ground-based turbines require far longer cycle times per part. Advanced cutting inserts can boost machining throughput with these materials, but achieving these gains requires proper tooling selection and proper implementation.

Compared with common steel, the heat-resistant super alloys (HRSAs) and other hard metals used in jet engines and ground-based turbines require far longer cycle times per part. Advanced cutting inserts can boost machining throughput with these materials, but achieving these gains requires proper tooling selection and proper implementation.

Cutting In Stages

The turning or milling of complex turbine parts progresses through first, intermediate and last stages. First-stage machining usually starts with large forgings that are often irregular in shape and covered with hard, abrasive scale. Intermediate steps conducted after the hard skin has been machined away account for about 80 percent of the material removed from turbine parts. Last-stage finish machining must achieve high tolerances on turbine components yet impart low stresses into thin structures.

In first-stage machining, the initial slow, rough-cutting pass so critical to producing a usable part is often complicated by interrupted cuts. Round insert geometries typically provide the best edge security in such applications. With no stress-raising corners, the circular shape is inherently strong.

As to grade selection, coated carbide inserts should be the cutting tools of choice. The carbide grade must withstand the shock of interrupted cuts while the insert edges survive the abrasion and micro-chatter brought on by the particle-filled skin. Inserts Sandvik Coromant offers for these applications have a hard fine-grain microstructure and thick titanium aluminum nitride coating. In turbine alloys, these features permit 10 to 40 percent greater productivity than more conventional carbide inserts can achieve.

Intermediate Cutting

Compared with slow first-stage machining, intermediate-stage machining provides turbine part manufacturers with a greater opportunity for fast metal removal. Taking advantage of this opportunity requires extra-hard cutting tool materials able to withstand high heat and abrasion to turn or mill turbine alloys at the most productive speeds and feed rates. In such applications, whisker-reinforced ceramic cutting inserts can sustain cutting speeds up to 1,000 sfm for 10 times the productivity of common carbide inserts. Careful orientation of the silicon carbide whiskers on the part of the cutting tool maker can deliver edge strength able to provide up to 20 percent greater productivity compared to other ceramics.

At high speeds, multiple passes on hard metals commonly cause edge notching of the insert, even on whisker ceramic inserts. However, ramping the insert—varying the depth of cut on successive passes—distributes wear along the cutting edge and extends edge life. It also reduces the risk of catastrophic edge failure midway through a cut.

An exception is made for titanium. Ceramic inserts at high cutting speeds generate too much heat to be used safely on this metal—the workpiece may combust. The optimum intermediate machining solution for titanium has proven to be coated carbide inserts at lower speeds.

The Final Cut

Final-stage machining refers to the last cutting passes made to achieve tight tolerances and fine finishes. Typically, final passes are done at low cutting speeds and shallow depths of cut. During this machining, thin-walled turbine components are vulnerable to machining stresses that can distort their shapes and shorten their fatigue lives. An extra-sharp insert used at a low feed rate can minimize cutting forces to protect these thin parts. A fine-grain coated carbide insert ground with a sharp finishing geometry machining a thin, hollow combustor ring made of Inconel 718 may be capable of 180 sfm and a feed rate of 0.004 ipr.

Another option is cubic boron nitride finishing tools. CBN puts little stress into thin parts. However, the edge security of the cutting insert is essential on large forgings, which can cost $250,000 or more. With edge temperatures exceeding 2,000°F, Inconel machining can be hot enough to melt the brazement holding the CBN tip in place.

Tip breakout has been a common problem leading many turbine manufacturers to shy away from CBN. However, one alternative is to sinter the CBN tips in place, eliminating brazing metal altogether. Further economy can come from inserts having multiple edges, substantially reducing the cost per edge. In place of uncoated carbide inserts, these tools can provide up to 10 times the productivity finishing hard HRSAs.

About the author: Mike Castner is director of rotating products for cutting tool supplier Sandvik Coromant.

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More