Brackets Are One Potential Win for 3D Printing

They may not be flashy, but they are necessary. Four reasons 3D printing can build a better bracket.

As additive manufacturing (AM) advances along with design software, the parts we see highlighted get more and more flashy. Mold inserts with complex cooling channels following the contours of a part. Topology optimized motorcycle frames with organic lattice work. Even 3D printed guitars.

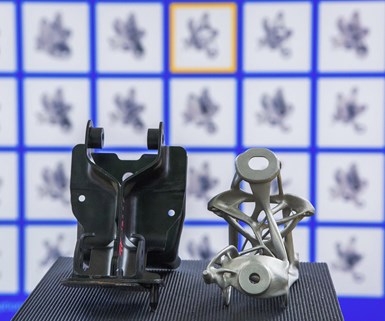

That’s not to say brackets don’t also get beauty shots, as this seat bracket for GM demonstrates (shown next to the assembly it was generatively designed to replace).

These parts are beautiful as well as functional, and help to illustrate the trajectory that AM is on. But these showy parts might not be the applications in which AM will make the greatest impact. That point of impact might instead be something more mundane: brackets.

This basic, but critical, component can benefit from 3D printing in many cases. Here a few reasons 3D printing can win for brackets:

- Avoid assembly. Rather than assemble a bracket from multiple pieces and off-the-shelf joiners, in many cases 3D printing makes it possible to manufacture the entire bracket as one consolidated piece. That means less labor and time spent putting brackets together, fewer fasteners and likely a stronger overall part.

- Reduce weight. When a bracket can be made as one piece via 3D printing, often some of its material can be removed. That weight savings translates not just to reduced material usage and waste, but frequently also into improved end-use performance. Consider a bracket used in an airplane — reducing its weight also reduces the plane’s fuel requirements, leading to a more efficient aircraft.

- Produce faster. For a complex metal bracket that would require multiple setups to machine, 3D printing may offer a faster solution. The ability to nest multiple parts inside a metal 3D printer enables manufacturing multiple brackets simultaneously in the same machine. For a bracket that might have been injection molded, the savings is even greater because 3D printing avoids the lead time of obtaining mold tooling.

- Use alternative materials. Not every bracket needs to be metal, even if it has traditionally been. For the right application, a 3D printed plastic bracket can be not only suitable but desirable. In addition to weight and time savings, plastic brackets may also be a better fit for certain applications such as consumer products with a limited lifespan and use near sensitive electronic components.

8 Times 3D Printing Built a Better Bracket

They may not be the most exciting application, but they are one of the most important. Here are eight instances in which a 3D printed bracket offered advantages over a conventionally produced one, from Additive Manufacturing Media.

Related Content

-

10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

-

5 Tips for Getting the Most From the Historic Return of North America’s Biggest Manufacturing Event

Plan. Explore. Think of the future. And oh yeah, the shoes. Here is how to get the most from the major manufacturing event that none of us have experienced in four years, and that many will be experiencing for the first time.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)