CAD/CAM Software Grows Customer Base, Product Offerings

Forward Technologies needed to expand its customer base and broaden its capabilities. With Mastercam CAD/CAM software, it was able to do just that.

Initially, growth opportunities for plastic component manufacturer Forward Technologies, then of Springfield, Ohio, were limited due to its arguably isolated location and small range of manufacturing capabilities. However, by moving two and half hours southwest to Cincinnati and leaning on Mastercam CAD/CAM software from CNC Software Inc. (Tolland, Connecticut), the company is now able make complex parts for a wide range of industries, ultimately growing its customer base.

In 2014, a group of four manufacturing professionals in the Cincinnati area decided to form a partnership and launch their own business. To quickly take advantage of the unique skillsets each person brought to the new venture, they decided to purchase Forward Technologies, an existing business complete with its own staff

and equipment.

There were two immediate problems with this acquisition: The first was location, and the second the lack of diversity in both products and customer base. Machining mostly plastic components, Forward Technologies had only four customers—one of which represented 97 percent of the company’s total business at the time of the acquisition.

To solve the first problem, the owners moved operations to a 10,000-square-foot plant in Cincinnati that is nearly three times the size of the previous facility. To solve the second problem, the company began to tap into the partners’ extensive network of industry contacts to secure contracts for manufacturing a more diverse range of parts in both plastic and metal. As a result, a steady stream of quotes started coming in even before the company moved.

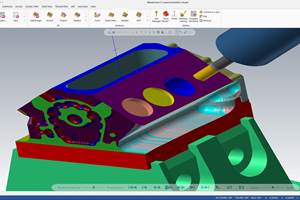

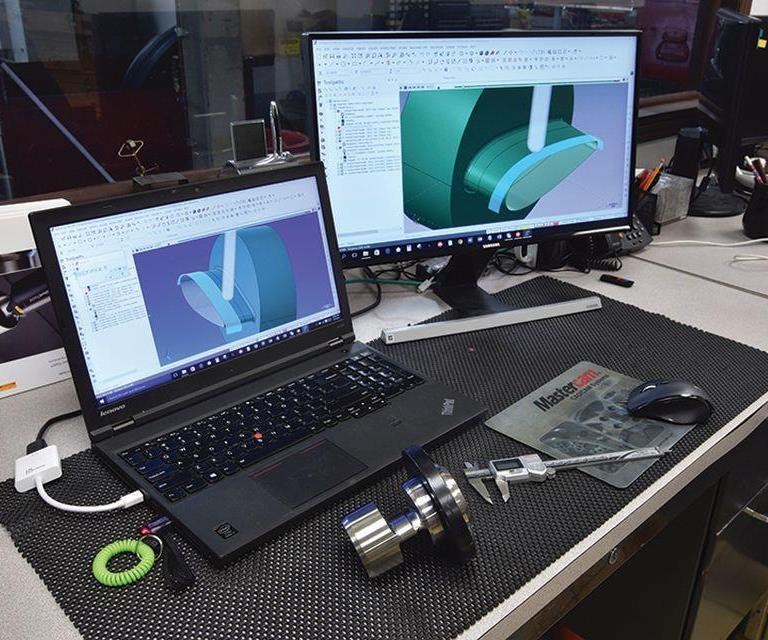

Scott Mason, a co-owner and vice president of manufacturing, says the key to capturing and keeping this business was to establish stable manufacturing processes for each new part so it would be manufactured efficiently and repeatedly each time. The company used Mastercam CAM software to do this, ultimately expanding its manufacturing capabilities to complex parts in a wide range of industries.

Mr. Mason, who had never used Mastercam, says he was surprised by how easy it was for him to learn the software and how well it could be adapted to a variety of manufacturing challenges. This became crucial as the volume of business quickly ramped up and the partners added a second shift.

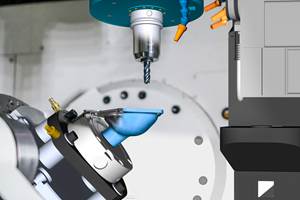

With each new application, Mr. Mason says he is constantly learning new things he can do with the software and ways he can take advantage of its more advanced capabilities. For instance, when 16 aerodynamically shaped Inconel structures required a substantial amount of surfacing, he says that Mastercam made it easy to manipulate the model to avoid interferences and create trichoidal tool paths blending complex surfaces. A programming and manufacturing process that in the past would have taken him three months was accomplished in just two.

In another application, the company made a cast aluminum medical furniture part that just barely fit in the machine’s envelope. Using a simulation model that integrated the part and the workholding solution, the shop was able to efficiently and safely navigate the tool to effective cutting approaches everywhere on the part, even cutting through the workholding solutions in some instances. Creating this single-setup manufacturing program took four hours.

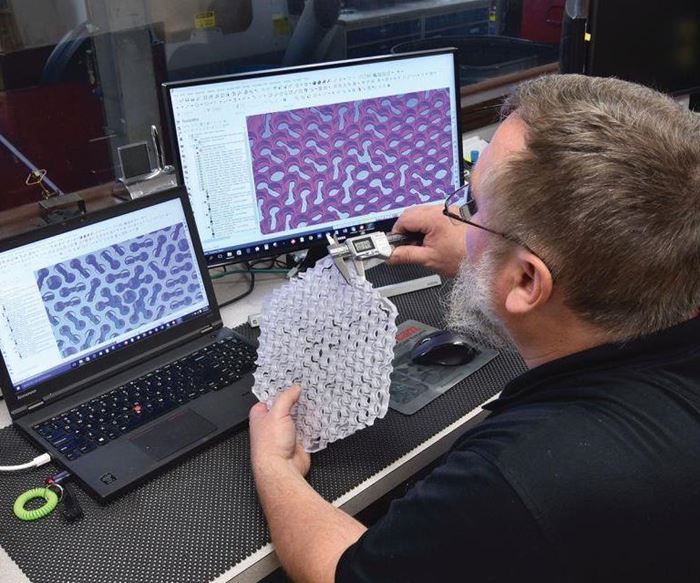

The software also helped the company precision-machine an acrylic component used in the energy industry that consisted of a 9-inch-diameter disk with 207 identical holes and numerous slots interconnecting them. Each part required hours of machining, but programming went quickly. Mr. Mason says all he had to do was mark one point for each hole. Then he drew a window to select all of the points and Mastercam automatically generated all 207 tool paths. He used the same approach for the slot tool paths. For those, he drew a line to indicate the position of each slot.

Using the CAM software’s more advanced capabilities has also helped the company increase the volume of its lathe work. When the partners first acquired the company, Mr. Mason says they sent a small bin of turnings to the metals reclamation center. Today, they send tractor-trailer loads on a monthly basis. The company uses Doosan lathes with live axes to turn barstock into four- and six-axis parts. They are programmed in Mastercam using the same tool paths and features that are available for programming mills, making it possible to machine many parts throughout multiple shifts in a single setup. This capability recently helped Forward Technologies secure a contract for an automotive mill-turned hydraulic component. “We program it in one place and manufacture it with one setup. That is a big savings for us,” Mr. Mason says.

Although Mr. Mason had to learn Mastercam on the fly, he says he was able to find answers to many of his questions simply by clicking on the question mark on the programming screen or seeking technical support from Mastercam reseller Fastech Inc. in Findlay, Ohio. Forward Technologies is also seeking to deepen the capabilities of machinists who are only using the software at a rudimentary level. For example, a younger programmer is making use of a self-paced, online lathe-programming course via Mastercam University to quickly learn how to better use the software.

The company attributes much of its growth to being able to create tightly controlled and highly efficient CNC manufacturing processes for a variety of parts in various industries. In just two years, it has gone from having just four customers to two dozen in diverse industries; grown from a staff of seven to 16 people; expanded from one to two 10-hour shifts; added four new pieces of equipment, including two lathes with live turning; and improved its manufacturing output by 400 percent. Also, Forward Technologies is no longer primarily dependent on a single customer. Even so, the business volume with that same customer continues to grow, as it does with most of the company’s other customers.

Related Content

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreBuilding A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

Read MoreImprove Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

Read MoreCAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)