Can Palletizing Reduce Your Setup?

Locating and securing blanks and then unloading finished workpieces can take a significant amount of setup time. For some applications, palletizing workpieces off-line and then clamping them in common receivers can achieve dramatic setup reductions.

Reduced in-cut time from faster machine tools puts increasing pressure on setup reduction to achieve throughput goals in the shop. Workholding accounts for two of the biggest setup problems. Specifically, these are repeatability of location from one workpiece blank to the next, plus transfer of work from one machine tool to another while maintaining relative position of related geometric features on the work-in-process.

Palletizing a workpiece blank off-line may eliminate probing for a datum on the initial setup and the need to re-establish a datum when moving from machine to machine. Saving setup time by eliminating load/unload variability is driving the application of palletized work in shops.

When loading, even the most conscientious operators are challenged to accurately place each blank in its fixture. Slight variation in position, especially for tight tolerance parts, can result in scrap and re-work.

Machine tool builders have made major advances in single setup processing using machine tools designed to perform multiple operations—single machines that can turn and mill for example. Even so, many workpieces require the processing services of more than one machine tool for completion.

Traditionally when loading a new job on a machine, accurate location of the blank or blanks must be established prior to the machining cycle. This is usually done with a touch probe or gage block.

Likewise when moving a workpiece from one machine tool to another, it is necessary to reload the partially machined part into a fixture or vise and then establish a datum point from which to continue the processing. Time can be lost in this transfer because of the need to re-establish location of the workpiece on the second machine tool.

To find out more about how palletization can eliminate these problems, we visited EROWA (Arlington Heights, Illinois). They have developed a systemized approach to shop automation with the goal of eliminating on-line setup of machine tools. While 100 percent elimination may be elusive, the company believes significant setup reduction can be achieved using a palletizing system. Here's how it works.

What Is Palletizing?

In most metalworking shops, pallets are associated with machining centers, flexible manufacturing cells, and systems. That association is correct. Use of pallet shuttle mechanisms, employing two pallets to 20 or more, has boosted the competitiveness of most shops that employ them. Loading workpieces off-line onto a tombstone or other fixture enables shops to make significant improvements in spindle utilization.

But there is another kind of palletizing. What EROWA and some other companies have developed is a systematic approach to workpiece loading and unloading. Using this system, a workpiece reference location need only be established once.

Once the location of a blank is established, relative to the pallet, that data can be captured electronically. Work can then be moved from a turning center to a grinder, or from a machining center to a CMM, without the need to relocate the reference point.

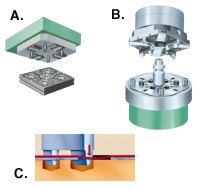

The system is composed of two components, a chuck or receiver, and a pallet. A workpiece blank is mounted on the pallet. For example, on a prismatic workpiece blank, one side of the cube is mounted to a pallet, usually attached with bolts. The pallet is then placed into a chuck or receiver and clamped. Using this setup technology, five sides of the workpiece are accessible to the machine tool cutter.

Palletizing a workpiece augments pallet shuttles and can give many of those pallet-shuttle benefits to single-table machine tools. Basically it's a building block approach. On single-worktable machines, palletizing work can decrease load/unload time. It takes only a few seconds to exchange pallets with the chuck or receiver. In these applications, more time is saved by the elimination of the need to re-establish a datum for each blank.

Why Palletize?

EROWA's palletizing system saw its first use in EDM, where it is still applied to the manufacture of graphite electrodes for die-sinking machines. In use, a blank of graphite is mounted to a standard pallet. The machining center on which the graphite is cut has a receiver for the pallet.

Alignments for the receiver are established from the receiver center line. The machine tool CNC knows where zero is. Likewise the ram on the EDM machine is fitted with a receiver. The machined electrode is clamped into the ram, which is also aligned from its center line.

The mold cavity blank is also mounted on a pallet. The machining center on which the cavity is cut has a receiver for the pallet. Alignments are established from the receiver center line and those coordinates are kept in the machine's CNC.

When the cavity is ready to go to the EDM machine for its final burn, a receiver in the bottom of the tank is aligned on center with the ram that holds the electrode. Setup consists of placing the palletized mold under the palletized electrode. Their alignments are within 80 millionths (±0.00008) of an inch. Correct orientation is set in the fixtures and the machine is ready to burn.

Once the various alignments are established on the machines, it is not necessary to re-establish them from one job to the next. That's where a significant amount of setup time reduction can be realized.

Standardization

In metalworking, standards among equipment makers have been elusive. Reluctance to establish compatibility between unlike machines and accessories carries over into both hardware and software.

While there are efforts underway to change some of this, achieving open architecture is a daunting task. Even if a common standard for pallets or T-slot sizes and distances were established today, it would be many years before the industry replaced its older non-standardized machines with standardized ones.

Much of the burden of standardization falls on the shop's shoulders. Tooling is an example. Most shops, whether they use 40 or 50 taper, will specify machine tool spindles with CAT, ANSI, or other standard so toolholders can be interchanged among various makes of machine tools.

For workholding, the problem of standardization is more complex because of the huge variety of applications. EROWA's workholding standard is to use common components to hold the blank and common fixtures to secure the palletized blank to the machining center, turning center, grinder, or measuring machine. Thus, once the part is palletized, it can be placed securely on any machine equipped with a compatible receiver or chuck.

Modularity

Standardization gives a shop the ability to interchange work among various machine tools. However, it is modularity that gives the shop a method of dealing with various applications.

If a shop made one part by the millions, then standardization of workholding, tooling, material transfer, and measurement would be sufficient to reap large manufacturing efficiencies. But such a single-workpiece shop is not reality. Even in automotive production lines, there are generally families of the same parts that must run on a given line.

Modularity is key to processing different sizes and shapes of workpiece blanks. In EROWA's system, for example, the chuck or receiver is designed to accept a very large selection of pallet configurations.

The chuck is the foundation of the modular system. In one model, a workpiece blank, 500 mm by 500 mm, can be secured. The chuck has four holes to accept draw studs that protrude from the pallet. The chuck contains the lock mechanism. Also there are four steel centering plates that give repeatable accuracy on the pallet system. Once in place, the pallet is clamped. Then, if a smaller workpiece is set to run after the larger one, the chuck is designed to accept this as well.

Accuracy

Repeatability specification for EROWA's system is quoted at 80 millionths of an inch. Other palletizing systems deliver similar figures. It is accuracy that makes the concept of palletization a viable solution.

Eliminating the variability of workpiece loading and unloading is a big step to more consistent quality. That's one major advantage to a palletizing system.

The design of the pallet and its receiver guarantee consistent placement of a workpiece in a machine tool whether it is done by hand or by an automated material handling device.

The critical component of this system is the steel centering part. It operates using the assumption that radial positioning, axial positioning, and clamping are separate functions within the chucking unit. One or four draw studs couple with four punched holes; or, hardened centering plates establish radial positioning.

For axial positioning, hard stops called supporting feet create hard contact between the chuck and the pallet. Once in contact, the four feet form a plane. The centering plate, in contact with the prisms, flexes slightly and self-centers. The action is repeatable, giving the system its accuracy. Position and repeatability of the centering plate amount to less than ±0.00008 inch in all axes, according to the company.

Clamping is achieved using a ball lock mechanism. The lock is positive. It is pneumatically actuated and designed to be fail-safe. Air actuates the opening of the chuck only. It closes mechanically, so if the air is cut off, the chuck remains securely clamped.

Is It For You?

Like any standard pallet, the pallet used on EROWA's system can be set up with a variety of workholding systems mounted to its surface. Different vises and fixtures can be mounted on the pallet. Three-jaw chucks or even magnet tables can be used to affix a workpiece to a pallet.

Key to gaining efficiency from the system is to incorporate the quick changeover features afforded by knowing the relative location of the receiver chuck and simply mating the pre-loaded pallet to it.

Once done, location is established for any subsequent process step that a workpiece will encounter. More process-intense workpieces reap even more throughput gains. Each handling saves a given amount of time. More handlings represent more savings—it's additive.

For shops that need high accuracy from location to location within the shop workflow, whether it is to maintain geometric relationships or to help eliminate load/unload variability, palletizing might be worth investigating.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)