Case Study: Chip Conveyors Run Production Efficiently

Hennig chip conveyors on Niigata machining centers maintain efficiencies and production on ductile iron castings used in heavy truck and military drive train projects at this Michigan shop.

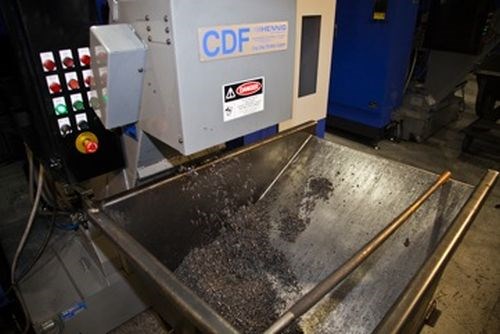

While machining large workpieces made from ductile iron for the heavy truck and military drive train markets, Acurate Gage of Rochester Hills, Michigan noticed an iron sludge buildup in its coolant tanks that required frequent maintenance and machine downtime. By incorporating four Chip Disc Filtration (CDF) conveyors from Hennig to run in tandem with its Niigata SPN 701 HMCs, the company was able to reduce downtime for maintenance.

Hennig’s magnetic chip disc filtration system caught the attention of the team at Accurate, because change-over seemed relatively easy compared to the traditional drum screen filtration systems. As Accurate’s Engineering Manager Mark Tario says, “Replacing the drum filter screen is not an easy task, in fact, it can be downright miserable. The Hennig disc arrangement seemed much easier to operate and maintain. The incorporation of rare earth drum and scraper assembly inside the conveyor appeared to be a great solution for minimizing the amount of cast iron fines reaching the coolant tank side of the system.” Mr. Tario notes the heavier-duty mechanical components and drive chains used on the Hennig conveyor could provide greater wear life and reduce likelihood of downtime.

Downtime for maintanence was perhaps Accurate’s biggest challenge. Machining cast iron creates considerable problems, such as the frequent need to replace conveyor chains, drum screens and other mechanical components that get infiltrated by the iron files and lock up.

Accurate found Hennig’s conveyor chains to be stronger and not need frequent repair and replacement. The discs can be removed and cleaned on a workbench rather than reaching through narrow access ports to wrestle with a drum-style filter. This entire process takes as much as two hours and screen replacements can be done in 30 minutes or less, Mr. Tario says.

Accurate has already installed four Hennig systems, just received an additional three and plans to purchase two more in the near future.

To see video of this installation, click here.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.