Chuck Selection: How The Experts Capture Optimum Efficiency

The factors considered by experienced workholding engineers reveal that choosing the right lathe workholding isn't a matter of meeting, but of exceeding, expectations.

Replace or revise. It's a choice every purchaser faces when updating technology. This is also true for workholding. The "replace" option only takes a simple phone call. The decision to revise requires working through a series of questions to find answers that can greatly improve production efficiency, quality and safety.

To determine the proper lathe workholding for the job, one must consider more than the size of the lathe and the chuck originally included with the machine. Key factors in choosing the right chuck include workpiece dimensions, the material of the workpiece, production volume and the shop environment. Many workholding suppliers can recommend a solution based on these factors, but the most resourceful supplier possesses a combination of experience and intuition to arrive at the best solution.

For instance, experienced workholding engineers examine the manufacturing process and application involved in excruciating detail. The fact is, most workholding strategies can be improved. The old adage, "if it ain't broke, don't fix it" no longer applies in a highly competitive, global marketplace. To succeed, you have to exceed. And that means re-evaluating every detail of a job. Some customers are struggling with their workholding and perhaps doing it wrong. Others are basically right but could grab another 20 to 30 percent efficiency.

Dialogue

Workholding experts engage in dialogue with their customers to learn the reasons behind what their customers are doing, what they have tried, what worked and what failed, and what improvements they would like to see. These engineers use further deductive reasoning and ask questions such as

- Are gripper marks on the part acceptable?

- Do you need seating confirmation?

- Is the part tapered, requiring a pull back chuck?

- Is a through-hole required?

- Is the workpiece bar, flange or center work?

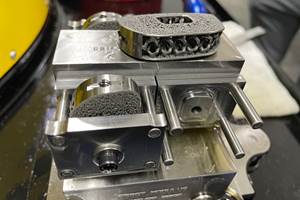

- These engineers are also trained to consider fixtures, stops, positioning pins, coolant/air blast or custom jaws. Short runs can sometimes gain efficiency with a quick-change chuck such as the one pictured in Figure 1 (above right).

There are many, many considerations when selecting the optimal workholding solution. A general selection guide is summarized in Table I, Jaw Chuck Selection Guide (the table is in a printable format).

Understanding Forces

It is important to understand the forces used in workholding. These include radial force (the inward movement of jaws toward each other), axial force (the pulling back toward the face of the chuck), and the combination of these two forces (as achieved with a pull back or power wing chuck).

Doing The Math

Even after workholding engineers come to a conclusion, their questions don't end. They have to prove their decisions are right, and these are procedures they go through. The workholding specialist will rough out a general concept of the chuck jaws and their holding position relative to the part.

The customer is then consulted regarding his or her feeds, speeds and depth of cut requirements. Finally, a series of calculations identifies how the workpiece is gripped during operation, whether there are any part distortions, if the chuck safely holds the part and more. Only after a workholding solution passes all of these tests do the engineers have a complete concept to present to the customer.

In short, a thorough examination of a process can lead to workholding solutions that optimize production with results that exceed expectations.

Solutions Are Not Always Obvious

A manufacturer of aluminum wheels questioned why he was not getting the same cycle times on certain machines. Before consulting with lathe workholding experts, he worked extensively with cutting tool manufacturers to find replacement inserts that delivered improved speeds and feeds. He also worked with the lathe manufacturer to find improvements in cycle times. None of these efforts proved to be completely satisfactory.

Then he approached the workholding experts. One of them, a trained engineer, realized that certain fittings in the customer's hydraulic system were restricting the flow of oil. A simple change in hoses and fittings eliminated the problem and improved the actuation rate of the manufacturer's hydraulic cylinder and functionality of the chuck. By improving the flow rate, chuck actuation dropped from 4.5 to 1.5 seconds. To the manufacturer, this benefit was as valuable "as finding some new wonder insert," to borrow his own words. Figure 2 (at right) shows the type of chuck used in this application.

Less Pressure

Recently, a major manufacturer of heavy-duty trucking couplings sought to improve a manufacturing process in which a turning operation was critical. Here, the chuck was suitable for the application, but the workholding needed evaluation. Kitagawa experts found the top tooling to be too stressful for the chuck, resulting in the need for chuck replacement every nine or ten months.

The engineers replaced each of the existing 15-pound top jaws with more efficient 4-pound top jaws. By replacing the top jaws and bringing the part closer to the face of the chuck to allow for lower hydraulic pressure, chuck wear and tear was minimized. (A replacement chuck, Kitagawa's N15 chuck, uses much less hydraulic pressure to grip the same part as securely as the company's previous workholding equipment.) See Figure 3 (below, right).

In chuck selection, it is helpful to keep in mind that the jaws usually have two functions. On one hand, they grip the component for safe machining and overcome all cutting forces. On the other hand, they establish workpiece location and orientation with a degree of repeatability to meet the customer's requirements.

Dealing With Deflection

Here's another example of the effects of proper chuck selection: a manufacturer's application was encountering workpiece deflection when the OD and the center hub were gripped. When the back face of the workpiece was machined, it was flat, but when it was released it was no longer in specification.

Again, lathe workholding experts worked with the customer to achieve gripping without affecting the hub, while allowing the machine to hold size and flatness. Kitagawa's PW style chuck (see Figure 4, below, right) was selected because it gripped the OD without distorting the features the customer was machining. The results of the operation were now predictable and within specifications.

How Many Jaws?

The number of jaws in a chuck is also a critical consideration, but a single point sums up the situation. If someone were to ask, "How can I hold an imperfect part every time?" the textbook solution may not always be correct. The shape of the workpiece determines the number of jaws needed, and the unlimited variety of workpiece shapes makes it impossible to reduce this issue to simple rules of thumb. That's where the experience of workholding engineers comes in.

Experience must also be backed up with follow-through. Be sure the workholding engineer is willing to test and verify tooling before committing.

Bang For The Buck

Investing in correct lathe workholding is a relatively inexpensive option that can substantially boost productivity. A state-of-the-art chuck represents only around 3 to 5 percent of the cost of the turning center or lathe itself. Yet the cost of a custom workholding package required to make thousands, or even millions, of good parts results in just a small added cost per part.

The improvement in efficiency that can be attributed to proper workholding is typically around 10 percent. When this improvement is applied over thousands or millions of parts, it represents a huge cost savings.

Consulting with lathe workholding experts, however, does not always result in a recommendation to replace the chuck. In an age when consultants are often called upon to improve a company's time management practices, application-driven companies like Kitagawa seem to be serving just that function in the world of manufacturing. They strive to provide solutions for customer needs as efficiently as possible. Goals, not components, determine what kind of workholding is needed.

About the author: Spencer Hastert is Vice President of Kitagawa Division of Sumikin Bussan International Corporation (Schaumburg, Illinois). He can be reached at (800) 222-4138, fax (847) 310-8787.

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=860)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)