CNC Grinding with Less Labor

As difficult as it is to find skilled machining personnel in general, finding skilled grinding personnel is more difficult still.

As difficult as it is to find skilled machining personnel in general, finding skilled grinding personnel is more difficult still. Meanwhile, many shops are doing more grinding than ever, as they respond to tight lead times by bringing grinding in-house. How can shops minimize their need for skilled labor in grinding?

In this article, Shane Farrant, national product manager for Toyoda Machinery USA, and Steve Earley, the company’s proposal engineering supervisor, suggest two ways:

1. In-process gaging. This is one of the most accessible ways to reduce human intervention in grinding, they say. Automatic gaging of the workpiece allows the CNC to respond to measurement trends resulting from the wheel’s changing diameter. With the process changing offsets on its own to maintain consistency, the wheel might not have to be dressed as often.

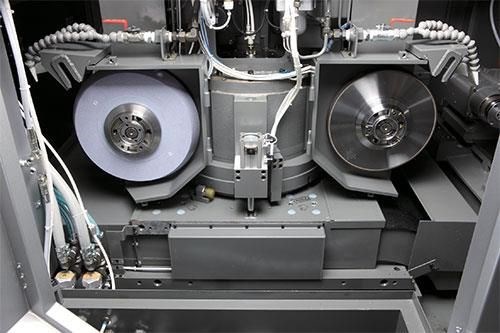

2. Universal grinding machine. This is a much bigger step, but potentially a valuable one. A universal machine makes it possible to switch between multiple grinding wheels in the same setup, so ID and OD grinding can be performed on the same machine, or rough grinding and finish grinding can be performed within a single cycle—with no extra handling or setup between these steps.

One step that might not be the answer is switching to a more expensive CBN wheel, they say. CBN’s effectiveness is material-dependent. It is good for grinding hard metals. In soft metals, the material might load the wheel to the same extent as a conventional wheel, resulting in a process in which dressing is just as frequent.

Related Content

-

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

-

When Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

-

Grinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)