CNC Technology For Mold Applications

Accessible control features play an expanding role in mold machining.

CNC technology is changing rapidly, and the changes are helping to improve the productivity of machine tools used in the mold industry. Faster central processing units (CPUs) are at the heart of many CNC changes. However, the improvements go beyond just faster processing, and the speed itself touches on many different CNC advances. With so much that has changed in recent years, it's worthwhile to present a summary of the state of mold-making CNC technology today.

BPT And Beyond

As CPU speeds have increased and CNC manufacturers have incorporated this speed into highly integrated CNC systems, there have been phenomenal changes that increase CNC performance. The faster, more responsive systems do more than just process program blocks faster. In fact, a CNC system that can process part program blocks at a very high rate may perform as well as a system that processes data at a slower rate, because there are other potential bottlenecks downstream that the overall feature content of the CNC system also has to address.

Most mold shops today intuitively understand that high speed machining requires more than just block processing time (BPT). In many ways, the analogy of a race car illustrates why this is so. Should the fastest car win the race? Even a casual observer of racing knows there is more to it than this.

First, the driver's knowledge of the race track is important. He has to know a sharp curve is coming so he can slow down just enough to take the curve safely and efficiently. CNC look-ahead performs a similar role in high-feed-rate mold machining, giving the CNC advanced knowledge of the sharp curves coming up.

Similarly, how quickly the driver reacts to what other drivers do, and other unpredictable effects, can be compared to the CNC's servo loop times—including position loop, velocity loop and current loop.

Consider also the smoothness of the driver's execution as he goes around the track. Skillful braking and accelerating have a significant impact on performance. Bell-type acc/dec in the CNC system gives similar smoothness to machine tool acceleration. Look-ahead helps here as well, because it allows many small acc/dec adjustments to replace an abrupt acc/dec change.

The analogy also applies in other ways. The power of the engine can be compared to the drives and motors. The weight of the car can be compared to the mass of the moving elements of the machine tool. The strength and rigidity of the car can be compared to the strength and rigidity of the machine. And the CNC's ability to maintain a specified path error can be related to how well the driver keeps the car on the track.

One other way the analogy relates to the state of CNC today is this: A car that isn't one of the very fastest may not need the most skilled driver. In the past, it was only high-end CNCs that could maintain high accuracy at high speeds. Today, mid-level and low-end CNCs are so powerful that they may also do an acceptable job. The high-end CNC still offers the best available performance, but perhaps for the machine you have, the lower-level CNC will permit the same performance as a CNC at the top of the line. It used to be that the CNC was the limiting factor determining the maximum feed rate in mold machining, but today the limiting factor is the mechanics of the machine. A better CNC won't deliver more performance if the machine itself is already operating at its performance limit.

Features Inherent To The CNC System

Here are some of the CNC features fundamental to many mold machining processes today:

- NURBS Interpolation. This technology for interpolating along curves instead of dividing curves into short, straight line segments is still gaining in popularity. Most of the CAM packages for die/mold applications today now have an option for outputting NURBS-formatted part programs. At the same time, more powerful CNCs have allowed CNC manufacturers to add five-axis NURBS capability, as well as NURBS-related features that deliver improved surface finish, smoother motor performance, faster cutting rates and smaller part program size.

- Finer command unit. Most CNC systems issue motion and positioning commands to machine axes using a command unit of 1 micron or coarser. Taking advantage of the increase in processing power, some CNCs today offer a command unit of 1 nanometer (0.000001 mm). This control increment is 1,000 times finer, providing for improved accuracy. It also provides for smoother motor performance, which can allow some machines to accelerate faster without increasing the shock to the machine.

- Bell-shaped acc/dec. Also called "jerk control" or "S-curve acc/dec," bell-shaped acc/dec allows a machine tool to accelerate faster than linear acc/dec. It also provides less position error than various acc/dec types including linear and exponential.

- Look-ahead. This is a widely used term, with many performance differences separating the way the feature works on low-end versus high-end controls. In general, look-ahead lets the CNC pre-process the program to ensure superior acc/dec control. The number of look-ahead blocks can range from two blocks to hundreds of blocks depending on the CNC. The number of blocks required depends on factors such as the minimum part program execution time and the acc/dec time constant, but 15 blocks of look ahead is probably the minimum acceptable value.

- Digital servo control. Digital servo technology has improved significantly, and most CNC manufacturers can now offer a digital servo solution. Advances include faster communications, serial connections between the drive and CNC, and faster and more numerous digital signal processors. These advances have combined to allow CNCs to control the servo loops more tightly and thus control the machine better.

The technology helps in many ways:

1. Increasing the sample speed of the current loop, combined with better current control, results in the motor heating up less. This not only extends motor life, it also means there is less heat transfer to the ballscrew and therefore improved accuracy. Increased sampling speed can also make possible a higher velocity loop gain, helping to increase the overall performance of the machine.

2. Because many newer CNCs offer a high-speed serial connection to the servo system, the CNC can now get a lot more information about motor and drive operation through this communication link. This has resulted in improved maintenance features.

3. Serial position feedback permits higher accuracy at high feed rates. As CNCs got faster, the position feedback rate became a bottleneck in determining how fast a machine could move. Conventional feedback is carried by a signal type that limits speed according to the sample rate of the CNC and the electronics of the external encoder. Serial feedback eliminates this bottleneck, allowing fine position feedback resolution even at high speeds.

- Linear motors. This technology has improved significantly in recent years in both performance and acceptance. Every IMTS sees more machining centers offered with linear motors, and to date, Fanuc has shipped more than 1,000 units. Some of GE Fanuc's advances have resulted in machine tool linear motors with a maximum force of 15,500 newtons and a maximum acceleration of 30 G. Other advances have led to smaller size, lighter weight and more efficient cooling. All of these changes serve to enhance the benefits linear motors offer over rotary motors—benefits that include higher acc/dec rates; superior position control and higher stiffness; improved reliability; and inherent dynamic braking.

Features Added From Outside:

Open-System CNC

Open-system CNC products have changed rapidly. The higher speed communications choices available today have led to many different types of open architecture. Most of these open-system CNCs integrate the "openness" of a standard PC with conventional CNC functions. The key advantage of specifying an open-system CNC is that it can allow the CNC features to remain current with the state of technology and the needs of the process even while the machine hardware ages. Among the capabilities that can be added to an open-system CNC via third-party software, some are more relevant and some are less relevant where mold machining is concerned. But across all shops using open-system CNCs, some of the most common choices include:

- Low-cost network communications

- Ethernet

- Adaptive control

- Interfaces to bar code readers, tool ID readers and/or pallet ID systems

- Mass part-program storage and editing

- SPC data collection

- Documentation control

- CAD/CAM integration or shopfloor programming

- Common operator interfaces

The last item is particularly significant. A growing requirement in the mold industry is for the CNC to be easy to use. An important component of this ease of use is commonality of operation from CNC to CNC. Typically, operators must be trained separately for separate machines because the CNC interface differs between machine types and between machine tool builders. Open-system CNCs provide new opportunities for working toward a control interface that's common throughout the shop.

Now, machine tool owners can design their own interfaces for CNC operation—and they don't have to be C programmers to do so. In addition, open-system controls can permit individual log-on so personnel performing various functions—operator, programmer, maintenance and so on—see only the screens they need. Eliminating unnecessary screens makes CNC operation even more straightforward.

Five-Axis Machining

Five-axis machining is increasingly being applied to complex mold work. The technology can reduce the number of setups and/or machine tools required to produce a part, thereby minimizing work-in-process inventory and reducing total manufacturing time.

As CNCs have become more powerful, CNC manufacturers have been able to add more five-axis features. Capabilities once found only in high-end controls are now available in mid-range products. Most of these features have to do with making five-axis machining easier to use for shops that have little five-axis experience. Today, accessible CNC technology can deliver all of these benefits to the five-axis machining process:

- Eliminate the need for qualified tooling

- Allow tool offsets to be set after the part program has been posted

- Support "machine anywhere" programming, so that posted programs are interchangeable from machine to machine

- Improve surface finish

- Support various machine configurations, so the program no longer has to account for whether the spindle pivots or the workpiece pivots. This is now accounted for by parameters at the CNC.

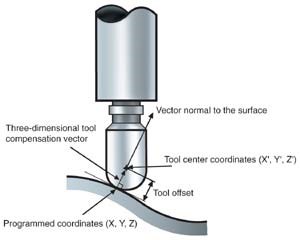

One example of a five-axis machining feature specifically suited to mold machining is ball-nose end mill compensation. In order to properly compensate for a ball-nose end mill as the part or the tool pivots, the CNC must be able to dynamically adjust the cutter compensation vector in X, Y and Z. (See illustration above.) Better finish is one benefit of keeping the tool's contact point constant.

Other five-axis CNC functionality can be separated into the features related to pivoting the tool; features related to pivoting the part; and features that allow the operator to manually move the tool to a new vector.

When rotary axes pivot the tool, the tool length offset that normally affects only the Z axis now has components in X, Y and Z. In addition, tool diameter offsets that normally affect only the X and Y axes also have X, Y and Z components. And because the tool may be feeding in the rotary axes while it's cutting, all of these offsets have to be updated dynamically to account for continuous changes in the tool's orientation.

A CNC feature called "tool center point programming" can take of this. The feature lets the programmer define the path and speed of the center point of the tool, while leaving it to the CNC to take care of the commands in the rotary and linear axes to ensure that the tool follows this programming. This feature makes the tool center point independent of the specific tool loaded into the machine, meaning (A) tool offsets can be input at the machine tool just as in three-axis programming, and (B) programs don't have to be re-posted to account for tool length changes. The feature simplifies programming and posting for machines that achieve rotary-axis motion by pivoting the spindle.

Machines achieving rotary motion by pivoting the workpiece use similar functionality. Newer CNCs can compensate for this movement by dynamically adjusting fixture offsets and rotating coordinate axes to match the part's rotary motion.

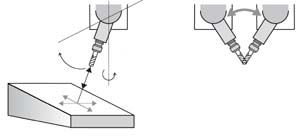

The CNC can also have an important role when the operator is jogging the machine manually. Newer CNCs allow the axis to be jogged in the direction of the tool vector . . . and allow the tool vector to be changed without the location of the tool tip changing. (See illustrations above.)

These features make a five-axis machine easier to use for 3+2 programming—the most common use of five-axis machines in mold making today. However, as new five-axis CNC features continue to evolve and gain acceptance, true five-axis mold machining is likely to become more common.

About the author: Bill Griffith is CNC product manager for GE Fanuc Automation North America, Charlottesville, Virginia.

Related Content

For This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

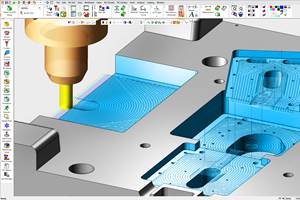

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreTwin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)