Coolant Delivery System Clears The Air For Specialty Manufacturer

According to this shop owner, this coolant delivery system met his objective of minimizing coolant usage while reducing or eliminating the misting problem.

Ward Staniforth and his wife, Ellen, had an intense interest in snowmobiles. In fact, Ellen had become the world drag racing champion in two separate classes of the winter sport. As a result of this interest, Mr. Staniforth started making special parts to enhance their snowmobile's performance. Friends and then dealers began asking him to supply them with parts, so he and his wife started their own business, WMS Enterprises (Evanston, Wyoming). In addition to a snowmobile product line, the company also manufactures parts for rock climbing equipment and for medical equipment. The shop has four CNC vertical machining centers and two CNC lathes, as well as standard milling machines and lathes.

At one point, the future of the shop seemed cloudy—literally. "Misting was a most serious problem in our shop, as a foul smelling cloud was hanging in the air," recalls Mr. Staniforth. He was aware that there have been widespread discussions about coolant delivery systems. While dry machining has been a recent trends that he was watching with interest, he saw that machines capable of milling, drilling or turning in the dry state present a very expensive alternative to flood coolant. Delivery of coolant through the spindle was also found to be very expensive. Special spindles and high pressures are often required, he learned. Regular coolant systems, which use large amounts of coolant to flood the workpiece, also presented problems in his shop. Wastes, contaminants and way lubricant were getting mixed into the coolant, necessitating an oil separation system to keep the coolant from going bad prematurely.

"Other systems we've tried in the past, such as spray coolant, released the coolant in such a fine mist that a coolant cloud can and often did develop in the shop," Mr. Staniforth says. Therefore, the challenge was to find a system that could deliver the coolant at low pressure without excessive misting.

For WMS Enterprises, the solution was a relatively new system called the Fog Buster from Hench Manufacturing Inc. (San Clemente, California). According to Mr. Staniforth, this system met his objective of minimizing coolant usage while reducing or eliminating the misting problem. The Fogbuster system is now used on the shop's CNC machines instead of the usual flood coolant. The system is adaptable to commands from the control unit and the strong airflow created works well for chip control, Mr. Staniforth says.

The system delivers coolant without fine atomization. A small stream of coolant is carried precisely to the work zone by an accurately aimed flow of air. In essence, the liquid spray is surrounded by the column of air, rather than mixed with the air, preventing the coolant from turning into a mist or a fog. This method allows the sprayer to produce a small but effective spray pattern several inches or more from its target. A precision needle valve at the sprayer head adjusts the coolant flow, an adjustment that Mr. Staniforth says is very easy to do on the shop floor.

One of the main benefits, in addition to a cleaner shop environment, is improved tool life. According to Mr. Staniforth, the cutting tools used in his shop could stand up to high temperatures and high cutting speeds but could not tolerate temperature changes, a problem he experienced even with flood coolant. Surface finish on parts also improved because the Fogbuster's accurate but strong air stream not only cooled and stabilized cutting tool and workpiece temperatures, but it also cleared chips. Finished workpieces are described as drier and cleaner.

The new coolant system operates on 10 to 20 psi and uses most types of coolant. The system comes with a 1/2 - or a 1-gallon coolant reservoir. A clear coolant bowl on the smaller model allows quick visual inspection of the coolant level, whereas the larger system comes with a sight gage. According to Mr. Staniforth, the system's quick mounting features allow it to be used on all of his machines.

Mr. Staniforth sums up his shop's experience with the non-misting coolant system: "Ellen and I breathe much easier. We save on coolant while meeting machining requirements with a system that accurately places the coolant where it is needed."

Related Content

Rego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreIMTS 2022 Review: Attention to Automation Extends Beyond the Robot and the Machine

The advance toward increasingly automated machining can be seen in the ways tooling, workholding, gaging and integration all support unattended production. This is the area of innovation I found most compelling at the recent International Manufacturing Technology Show.

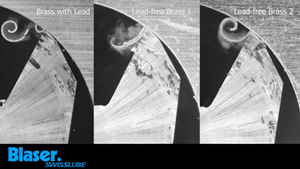

Read MoreHigh-Speed Videos Analyze Machining Processes in Fine Detail

Blaser Swisslube captures the machining process, chip formation and behavior of its Synergy 735 metalworking fluid through high-speed, macro photos and videos.

Read More168 Manufacturing's Coolant System Automates Delivery

PMTS 2023: FullShop systems monitor and replenish all CNC machine sumps with optimized top-off ratios before the coolant runs low.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More