Crossing the Skills Gap One Student at a Time

Every year, thousands of high school and college students who are enrolled in public career and technical programs make their way to the SkillsUSA national-level championships to compete for scholarships and awards. These students are the best in their states and are part of a growing movement to ensure that America has a skilled workforce.

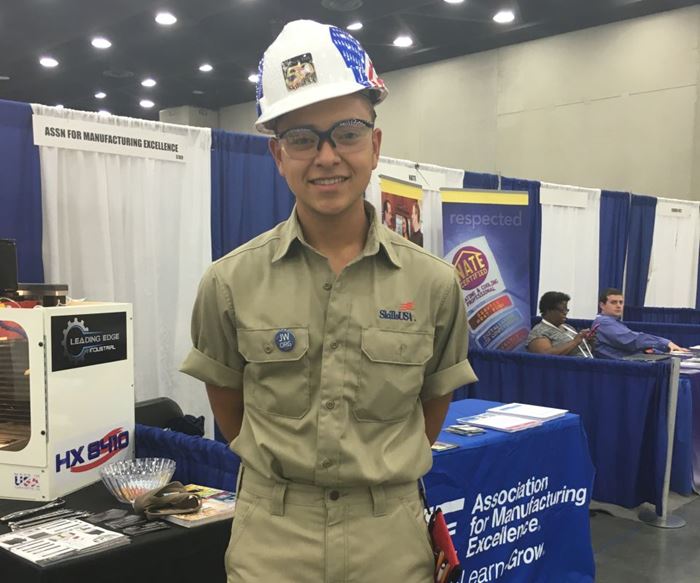

Frances didn’t think he would make it to the SkillsUSA championships.

“The competition was really tough,” he said. “There was someone that I thought was better than me because she was faster.”

Frances is one of the thousands of high school and college students who take part in the competitions that SkillsUSA hosts in their efforts to prepare the next generation of America’s skilled workforce and overcome what many see as a growing skills gap.

The so-called skills gap is a topic that I’ve heard a lot about during my time as an editorial intern at Modern Machine Shop. Older generations are retiring at a rate faster than young people can replace them, and as they leave, they take with them a lifetime of tribal knowledge. Unfortunately, according to some, there aren’t enough young people with the required skills to successfully replace them. While the skills gap is an issue that concerns many in the manufacturing industry, what are people actually doing to address it? That’s where organizations like SkillsUSA come in.

Formerly known as the Vocational Industrial Clubs of America (VICA), SkillsUSA is a nationwide organization that trains public high school and college/postsecondary students who are enrolled in career and technical education programs to become skilled workers in their desired fields. Since its founding in 1965, the organization has served 12.2 million members. As part of its mission to prepare students for entry into the skilled workforce, SkillsUSA hosts a variety of local, state and national competitions where students can showcase their skills and compete for awards.

I recently had the opportunity to attend the final competition day of the 2016 SkillsUSA national championships. and I have to say, it was mind-blowing. This year, the championships took place in Louisville, Kentucky, at the Kentucky Exposition Center and the Crowne Plaza June 20-24. In order to make it to the national-level competition, each competitor first had to earn a gold medal in their state.

As we walked around the exposition center and watched a wide variety of competitions ranging from video-game design to CNC programming, the level of talent and dedication that it takes to make it to the national-level championships quickly became apparent. This year, SkillsUSA hosted more than 6,000 contestants in 100 different skills and leadership contests. I watched as kids younger than me displayed skills that I would have expected to see from industry veterans, not 16-year-olds.

Of course, the real reason I was there was to view the manufacturing portion of the competition. Science, Technology, Engineering and Math (STEM) programs are a well-established focus of SkillsUSA as evidenced by the wide variety of competitions we observed as well as by the overwhelming support that the industry offers to the individuals who are participating in these competitions. (One judge we spoke to told us that in the past three years, eight students had been hired straight off of the competition floor by big-name companies like Toyota and Nissan.) We saw a huge variety of manufacturing-related competitions, including additive manufacturing technology, CNC milling and turning, and robotics and automation technology, to name a few. Each of these competitions required specialized equipment and donated materials that the students could use to showcase their skills. According to the organization, the 2016 SkillsUSA championships received more than $36 million in donated time, equipment and materials. There were also scholarships available for students who placed in select competitions.

When we first entered the competition, we were told that SkillsUSA is full of big fish from small ponds, but it’s where the sharks come out to play. Students like Frances train year-round for the opportunity to compete at the SkillsUSA championships. The competition is tough and many students walk away without a medal to show for their hard work. However, it is the hard work and time spent training that many students claim as the most important takeaway from their journey to the national championships. Regardless of whether or not they come away with a medal, the students who participate in SkillsUSA leave it having been better prepared for their future careers.

Related Content

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read More8 Ways to Increase Productivity on the Manufacturing Floor

When it comes to machine shop productivity, continuous improvement depends on efficient employees, equipment and processes.

Read MoreFinally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More