Digital Manufacturing Comes of Age

Sponsored ContentDigital manufacturing will see a much larger footprint at IMTS 2020, where you’ll see not theory, but proven and practical applications of digital tools.

As digital tools become more widespread, more attendees at IMTS 2020 will be looking for ways that software can provide practical solutions to manufacturing challenges.

A lot of manufacturers coming to IMTS 2020 will have digital manufacturing on their minds. As digital technology in the manufacturing world continues to find its footing, many see it as necessary for competing in the marketplace. According to AMT Vice President and CTO Tim Shinbara, digital tools are firmly establishing themselves as essential for simplifying and improving manufacturing businesses.

According to Peter Eelman, IMTS visitors will find digital solutions that they can implement today.

Every investment that a shop makes is a business decision, which means that every investment has to pay for itself,” Shinbara says. “What data-driven manufacturing does is provide the infrastructure to improve how a business runs.” Essentially, these digital tools are designed to provide resources for making informed decisions on how to run a shop.

Cutting Tool Management

Cutting tool management is a vital part of the daily functioning of every machine shop, as no chips are flying without the right tools in stock. Some companies have recognized this and developed digital tools to help manufacturers keep accurate digital records of their cutting tool needs.

IMTS will feature digital technologies that improve facilities’ ability to monitor their tooling needs.

Some manufacturers create a “digital twin” that represents the tool’s current state of wear, temperature, positioning and vibration. In addition to helping optimize the cutting process and predict tool life, software can keep track of stock and even the location of cutting tools to improve the users’ ability to prepare for upcoming jobs. The software fundamentally does the work of keeping track of the tools so that the user can make informed decisions.

Machine Monitoring and Facility Management

Machine monitoring has evolved beyond individual machine data collection. Now systems are becoming integrated and connected across the entire factory floor.

Monitoring machine uptime is becoming more and more common, and manufacturers are finding more ways to exploit this data as the practice evolves over time. Keeping track of this data can help managers make more informed decisions to address issues with production. If, for example, a high-volume job is showing frequent downtime because of part changes, the facility manager has exactly the information needed to justify investing in automated solutions for changing out parts.

Machine monitoring is coming into its own as manufacturers find ways to exploit machine data to make informed business decisions.

More importantly, machine monitoring systems can provide a facility with the tools needed to enhance the contributions of the people working there. These systems can identify bottlenecks that slow down jobs, helping the manufacturing team to gain a clearer picture of what processes need their attention. If the data shows that one process is slowing production, it provides a focal point for shopfloor personnel to develop improvements that can drastically cut down the time a part spends in the shop.

Machine monitoring is not a solution in and of itself. Rather, it is a guide that can illuminate problems in a process, enabling users to fix those problems on their own. Whether the solution is to retrain an employee, develop a new process or invest in more advanced machinery will depend on the problem. However, solving that problem is impossible until you manage to identify it. That’s where this technology can help.

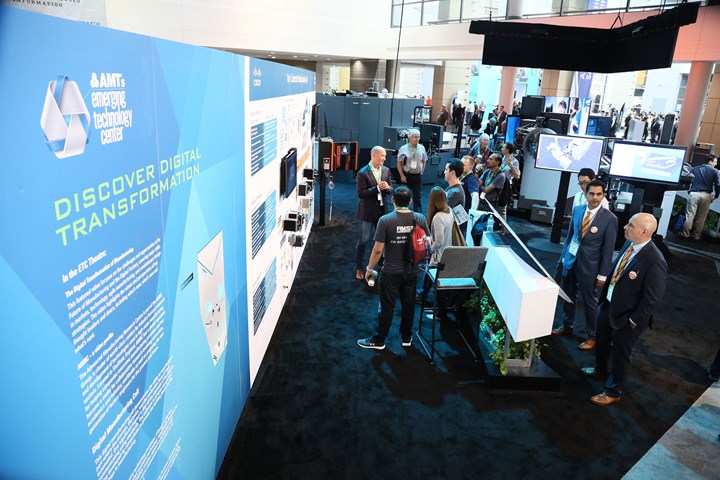

AMT’s Emerging Technology Center at IMTS provides hands-on educational demonstrations to help manufacturers grow more familiar with new technology, including digital tools.

Preventative Maintenance

Another emerging area in which data-driven manufacturing is proving its value is in preventative maintenance. Few things are more expensive than repairing a large machine, as the loss in productivity magnifies the drain the busted equipment has on a manufacturing firm. Fortunately, newer digital tools can avoid unplanned repairs by scheduling preventative measures that are less expensive and more effective than making repairs after a breakdown occurs.

This technology is an outgrowth of standard machine monitoring. However, it takes advanced software to analyze the fail states of machines, identify patterns in machine data that precipitates these breakdowns, and identify maintenance needs before anything goes wrong. While it often takes months for software to recognize the problems that can shut down a machine, once a preventative maintenance system familiarizes itself with your machines, it can drastically reduce the number of breakdowns you experience, paying for itself many times over.

Out-of-the-Box Digital Tools

The Athena voice interaction software was introduced at IMTS 2018, where attendees were able to interact with the software and speak with experts on its use.

One of the most common concerns with adopting any new technology is the time, training and resources needed to introduce it into the mix. With new digital tools on display at IMTS 2020, attendees will find solutions that are easier to implement than ever before. This includes more modular options that are accomplishing more tasks in a single installment, offering more interoperability with minimal training required.

Rather than needing 2-3 pieces of equipment each built with its own interface, and then struggling to connect them all to each other, users can introduce fewer components with more simplified means of integration with other pieces of equipment on the factory floor. This degree of consolidation, and sophistication, brings multi-tasking to a whole new level, and alleviates concerns with getting new technology up and running as soon as possible.

According to Shinbara, “Those thinking more intentionally about integrating their machines on a larger digital scale are setting themselves up to get the most benefit of these trends.”

A New Manufacturing Ecosystem

Visitors to IMTS will have the opportunity to attend conferences that discuss the practical applications of advanced technologies in the manufacturing world.

Many of these technologies have been developing for a while. But according to Shinbara, what’s emerging now is the practicality of making these disparate components of manufacturing technology work together. Or as he puts it, “These tools create super users without adding extra buttons to the machine.” Eelman agrees: “At this IMTS you’ll see very few significant components of the manufacturing enterprise that aren’t digitally enabled. It’s a whole new way of operating, and it’s something that manufacturers can implement now.”

Another component of the evolving digital landscape is standardization. IMTS introduces you to resources driving digital connectivity forward, such as MTConnect, a set of open-source interoperability standards that establishes a common language for equipment and devices to interact on the factory floor. The benefits of data-driven systems, like those using the MTConnect standard, offer increased productivity, detailed system monitoring, and real-time data to make informed decisions.

Looking to the future, attractions such as AMT’s Emerging Technology Center add another dimension to the IMTS experience, devoted to ground-breaking disruptive technology making waves in manufacturing.

The theme for IMTS 2020 is “Digital Manufacturing Implemented,” drawing focus towards the myriad ways digital technology is coming into its own.

For these reasons, the theme of this IMTS is “Digital Manufacturing Implemented.” Reflecting this theme, AMT has unveiled a new floor plan for IMTS 2020 that dramatically increases the size of the Quality Assurance and Additive Manufacturing Pavilions by more than 10 and 40 percent, respectively. The plan also consolidates the EDM Pavilion into the Metal Cutting Pavilion, which has been renamed the Metal Removal Pavilion.

IMTS 2020 runs from Sept. 14-19, will occupy all four buildings of Chicago's McCormick Place and is poised to offer more than 1.42 million sq. ft. of exhibit space. For more information, check out imts.com.