Extreme Tool Setting

A plant performing 79,000 tool setups per year measures these tools with one presetter and two gatekeepers.

For its 26 machining centers alone, PHD's Huntington, Indiana manufacturing facility has 4,875 tools in its active library. And "active" is the operative word. The rate at which tools are swapped in and out of machining centers is increasing. Last year, the plant did 63,717 tool setups. This year, it will do more than 79,000. No matter how you look at it, this plant uses a lot of tools.

Yet just one tool presetter measures all of the relevant data for all of the tool setups for these 26 machines. The software associated with the presetter manages lathe tooling as well. Two employees, one for machining centers and one for lathes, serve as the gatekeepers who maintain the integrity of this information. In short, while the plant uses a lot of tooling, it has a tightly controlled and centralized system for keeping that tooling in order.

PHD started building this system about a decade ago. At that time, it wasn't clear just how important the system would become. The company's business is changing. This maker of automation components—including cylinders, grippers, slides and rotary actuators—is seeing lot sizes and leadtimes shrink, while the number of product designs proliferates. In greater numbers, customers are asking for just-in-time service at the same time that they ask for custom products in place of catalog items. These changes are good, because PHD feels particularly capable of meeting these demands. However, the response to the demands is effectively transforming the Huntington production plant, along with a sister plant in Fort Wayne, into something more like a job shop.

However, the difficulty is that PHD lacks many of a job shop's options. In a job shop, a smaller number of machining centers might have substantial tool capacity in each machine. The shop might equip these machines with a standard complement of general-purpose tools that could be applied to almost any job coming in the door. In other words, a job shop wouldn't have to swap out tools so much.

PHD can't afford these kinds of concessions. It can't afford to devote that much floorspace to tool magazines, and it can't afford to hold that much tool inventory in every machine. Nor can it afford the cycle-time compromises that come from using general-purpose tooling instead of tools specifically suited to specific details of the part. What this plant needs is a system controlled and responsive enough to handle a large volume and variety of tooling. The plant had the foresight to begin putting such a system in place in 1994.

Over the years, the system has reduced human error, reduced the plant's overall scrap rate and improved the change-over time between jobs. Today, this system is facing a challenge, but it's not a challenge related to effectiveness. The challenge has more to do with physical limits. Part of the system's elegance lies in the fact that one presetter can serve so many machines, but the plant is now running this presetter around the clock. At 79,000 tool setups, the plant is pushing the upper limit of how many tools per year a presetter can measure.

Year One

The first presetter that the plant installed, like the plant's current model, came from Zoller, Inc. (Ann Arbor, Michigan). Even though the model PHD was using in 1994 was quite possibly the most sophisticated presetter installed in the United States at the time, the technology has improved significantly since then. The plant still has this first model sitting in a corner, because the plant can't find a buyer for it. The current model, purchased 4 years ago, beats it handily in terms of both precision and ease of use.

At least a year went by before presetting was integrated into the plant's process in something like the way it is today. The presetter itself is only part of a package that also includes tool management software—a vital element for using the presetter well. Tooling technicians at this plant used that first year to populate this software with the shop's preferred tools. They assigned tool names and ID numbers, associated toolholders with the tools, and input nominal dimensions and cutting parameters for the plant's various workpiece materials. All of this information had to be entered one tool at a time, in spare moments as PHD's production continued. Only after a year was there enough information in the system that a sizeable proportion of the plant's tools could be called up from memory instead of being entered for the first time. The tool crib personnel called up tools in this way, but just as importantly, so did the programmers. Their ability to select from a common reserve of tooling saved them time and guesswork, and it made the process more consistent by ensuring that standard tools were used in standard ways. At about this same time, the presetter itself was connected to the shopfloor network.

There was resistance from the shop floor then, and understandably so. Operators had long been accustomed to keying in their own tool offsets, and in many cases, even measuring their own tools. Now they were being asked to hit "cycle start" on programs using tool data they had never even touched.

But part of the problem had been the need for human beings to "touch" the tool data. Miskeying information was a frequent source of error. Because of this and other error sources, the plant's scrap rate used to stand at 7 percent. Tooling and process engineering manager Pat Young says networked presetting was adopted as just one component of a plant-wide effort to address such sources of error. This effort also included rethinking processes, improving fixturing and enhancing training—a team effort, Mr. Young stresses. Thanks to these measures, the scrap rate is now down to 1.5 percent.

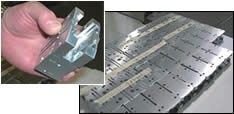

The presetter today is the control point for initiating every new machining job. The plant's objective is that an operator should never have to leave the machine to get tools or tool-related information. Tool/toolholder assemblies that are set up and measured in the tool crib are sent to the appropriate machine tool on a cart, arriving there well before the job is run. The tool sheet arriving with this cart tells the operator which pocket in the tool magazine should receive each tool. The operator then obtains the tool offsets by downloading them directly to the CNC across the shopfloor network.

Connecting the presetter to a network, and not to any machine or cluster of machines, was the choice that allowed this presetter to serve the entire shop floor. Mr. Young says various safeguards have been necessary to make this approach to using the presetter more reliable. One example is the use of a software program to automatically clear the system of any tool data more than 2 weeks old. Mr. Young says experience has been the best teacher for revealing where safeguards such as this one are needed.

Keeping Control

The tool library has to be safeguarded, too. This database of tools, large though it now is, provides programmers with the range of tools they have available, as wells as the machining parameters that have been demonstrated to be effective with these tools. The integrity of this library contributes directly to the effectiveness of PHD's process. For that reason, restricted access is another important element of the system. A gatekeeper is needed to guard the information.

Or more specifically, two gatekeepers are needed—one for machining centers and one for lathes. Darrin Colbart and Jim Wilson are the tooling technicians who not only monitor the plant's tooling inventory, but also enter and modify the tool data in this library. If a programmer wants to use a tool that doesn't exist in the system, then he comes to one of these men to make the request.

Mr. Wilson is the lathe guy. The fact that he uses this system might seem surprising, because the lathe tooling has no use for the presetter. For stationary tools, the plant uses quick-change tooling from both Kennametal and Sandvik Coromant to ensure repeatable tool location when tools are changed. For live tools, each lathe uses a probe to measure tool length. But despite the fact that the presetter isn't needed, the software accompanying the presetter is still valuable for managing the tooling.

For just the lathes alone, the plant uses a lot of tools. Ten turning centers draw on 837 different turning tools. In addition, any particular turning machine uses a lot of tooling at one time. When PHD buys a turning center, the standard complement of tool turret positions is just a starting point for the company. This plant looks carefully at each machine's potential use to decide just how many live tools and how many stationary tools it needs. It buys additional live tool heads and multiposition toolholder accessories not only to achieve the right mix of fixed versus live tooling, but also to increase the number of tool positions available. Most of these accessories have come from Euro-Technics (Huntley, Illinois), while accessories for the larger lathes come from Exsys (San Antonio, Florida). On one of its turning machines, the plant adapted the lathe to have 45 tool positions. Thus the tooling cart that arrives at a lathe might be just as stocked with tooling as the one that arrives at a machining center—and the tool sheet generated by the software is just as useful for instructing the operator in how to load these tools.

Employee Acceptance

The cutting tool is the element of any machining process that introduces the most potential for variability. One machine can run many different jobs, and the same workholding can hold many parts, but the required mix of cutting tools is almost certain to be different from job to job. Add to this the variation that might come from different programmers favoring different tools and choosing different parameters. For PHD, the value of presetting is not just to be found in measuring tools—though this is vital—but also to be found in the role that presetting plays to help take control of the tool-related process variation.

"It really is the hub of our process," Mr. Colbart says.

A clue as to how well tool setting has now been integrated into the plant can be seen in the operators' level of acceptance. Many operators who work with the system now were also operators before presetting. (Average seniority at the plant is 14 years.) Any resistance on their part to using tool offsets transferred across a network was overcome long ago. Mr. Young says the resistance now comes on those rare occasions when the system happens to be off-line.

"It used to be that no one trusted offsets they didn't enter themselves," he says. Now, personnel are more vocal when they have to hand-key information.

Related Content

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read More6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. Derek Korn, Production Machining’s editor in chief, shares suggestions from a CNC machine shop.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)