Features for More Flexible Measurement

To support a variety of applications, materials and workpiece sizes, measurement and inspection equipment suppliers are offering features such as automated measuring and multiple sensors.

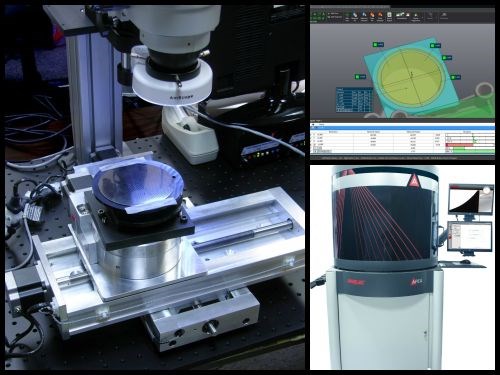

While measurement and inspection are necessary parts of the manufacturing process, the right equipment and features can help reduce the time and operator involvement required and limit the number of machines and steps. Fully automated systems such as Parlec’s Apex profile measuring machine and those with one-touch measurement like the Mitutoyo Quick Image 2D optical measuring machine can speed this step while reducing operator error. Other systems emphasize flexibility and diverse capability, such as the Zeiss O-Inspect which can be equipped with three different sensors to accommodate a range of workpiece sizes.

Click the image above for a slideshow featuring these and other measurement and inspection products.

Related Content

-

Building an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

-

How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

-

How to Choose the Right Cut Off When Measuring Roughness

Measurement results for surface finishing parameters can vary depending on the filter parameter (Lc), also known as the cutoff.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)