Five Go-To Machining Technologies

There are a number of ancillary machine tool technologies that shops can use to become more efficient and effective. Here are five that I appreciate.

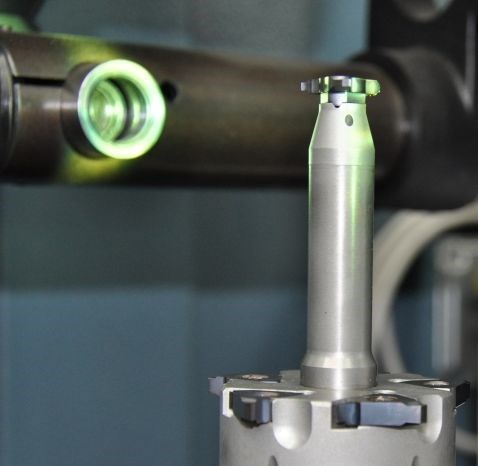

Toolholder assemblies for an upcoming job can be measured in seconds using a presetter, without the machine being interrupted.

We all know what opinions are like. That said, I thought of five pieces of ancillary machining equipment that I feel many shops can leverage to their success:

- Tool vending systems

- Tool presetters

- Machine tool probes

- High-pressure coolant delivery

- Shopfloor CMMs

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

5 Things CNC Operators Must Know About Sizing Adjustments

For CNC operators, sizing adjustment is an essential skill. Keep these points in mind when training new CNC users.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)