Flexible Transfer System Is “Factory within a Factory”

Jebco Manufacturing needed to increase productivity with limited floor space. The TFL 400 transfer system from Gruppo Riello Sistemi increased productivity and flexibility without the need for multiple machines.

Jebco Manufacturing Inc. of Colborne, Ontario, had reached its limit. To increase its capacity, the company needed to buy more machines; however, limited floor space kept it from doing so. Instead, Jebco turned to the experts at Gruppo Riello Sistemi North America (GRSNA) located in Windsor, Ontario, who suggested installing a TFL 400 rotary transfer system. The machine’s high level of flexibility enabled Jebco to increase its own manufacturing flexibility without the need to purchase multiple CNC machining centers.

Jebco specializes in the precision machining of OEM nonferrous components. With an 80-person workforce and a product line that includes valve housings, the company serves major equipment manufacturers in the automotive, transportation and industrial industries. Its facility is home to technologically advanced equipment for high- and medium-volume machining.

Over the years, the company has grown more competitive by sourcing high-quality, low-cost forgings, castings and extrusions. Still, it needed to find better ways to meet or exceed customer-driven project requirements and timelines. It did this by purchasing equipment that provides flexibility, quicker setups, faster cutting rates and enhanced process capabilities. By placing a great deal of time, resources and development into serving raw-material suppliers and using the latest technologically advanced equipment, tooling and logistics, Jebco says it meets the frequently changing needs of its customers.

One such advanced technology supplier, GRSNA, has worked with Jebco since 2010, when the company began installing Riello Sistemi SpA rotary transfer machines. Jebco’s most recent addition from Riello Sistemi was the first TFL 400 in operation in North America. “We are very pleased to supply and fully service to Jebco the first TFL 400 for the North American market,” says Jeff Grubisich, president GRSNA North America. “Riello is more than a brand, it is a proud family that has more than 50 years of experience in the rotary transfer machining industry worldwide. A Riello machine has proven to be an excellent investment because the majority of Riello machines are still in production on our customers’ floors more than 20 years later.”

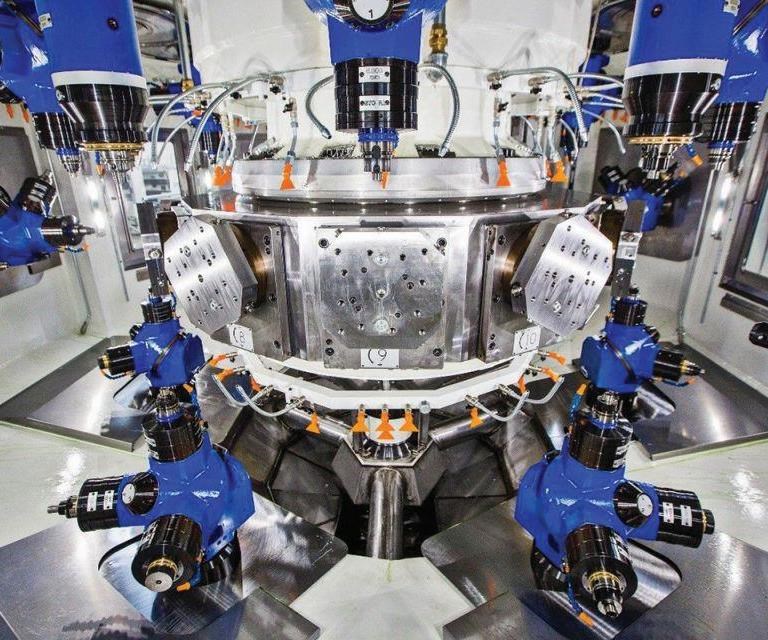

The TFL 400 is a flexible machining cell consisting of 21 independently operated three-axis work modules arranged around a 12-station rotary table. Sixteen of the three-axis modules include a three-position tool turret, while the table includes rotary B-axis fixtures at each station. This strategic system combines the high-production capacities of traditional transfer machines with the flexibility of advanced machining systems such as the Riello Vertiflex machine. For Jebco, the flexible machining cell is a more feasible alternative than a traditional bank of machining centers because it occupies less floor space, requires less manpower and provides greater productivity.

Scott Larsen, general manager at Jebco, says the throughput, almost equal to a dedicated transfer line, combined with the ease of change-over and ability to run different parts are key features he appreciates on the TFL 400. It is able to run both fixture plates and self-centering chucks. Best of all, it resolved capacity issues by enabling the company to expand into other product families within the same machine, saving significant capital. Although it had a higher purchase price than older transfers, it had better throughput, he says. Other key features include user-friendly controls and productivity rates as much as 15 times those of a conventional machining center. According to Mr. Larsen, Jebco benefits from its reliability, minimal downtime and the ability to run more than 5,000 hours per year.

Process Manager Kevin Chute says he is most impressed by the TFL 400’s refined user interface as well as the machine’s “seemingly infinite possibilities of machining process options” with its 21-spindle, 53-tool capability that spreads over 12 stations. It can output the equivalent of a large bank of conventional four-axis milling machines, he says.

Aside from the flexible transfer machine’s advanced features, Mr. Chute appreciates the quality of service provided by GRSNA and Riello Sistemi SpA (Italy). “GRSNA’s technical department’s response time has improved greatly over the years, and we are now at the point where it feels like they are right here on-site at Jebco,” he says.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)