For Enhanced Spindle Performance

There are a lot of things that a job shop can do to improve the performance of a machining tool spindle.

There are a lot of things that a job shop can do to improve the performance of a machining tool spindle. The following suggestions and illustrations come from Chris Hetzer, vice president of engineering, and Jeff Pfeiffer, manager OEM sales, for SKF Precision Technologies (formerly Russell T. Gilman, Inc.), (Grafton, Wisconsin).

Monitor That Spindle

Installing a spindle monitoring and recording unit (SMRU) helps keep track of critical maintenance issues. Maintenance of spindles is hard to predict because they are designed to work in a certain temperature range for a certain period in time. For example, when operated at 15°C above normal, grease life decreases by a factor of 2. SMRUs record temperature, speed and running hours. In one brand of these units, the SKF iSpindle SMRU, the information is stored in a histogram form that provides the maintenance engineer with information to assess how long the spindle has been running and to make a prediction of the remaining grease life. The unit can be integrated into the spindle or bolted to it. A maximum of 255 uniquely addressable units can be connected to a wireless wide area network. PC software is available for configuration of the SMRU's settings and displays.

Ceramics Are Cool

Consider replacing a spindle's bearings with hybrid ceramic bearings. On a grinder, for example, 25 percent higher rpm can be achieved by replacing steel ball bearings using oil/air-mist running at 10,000 to 15,000 rpm with hybrid ceramic bearings and synthetic grease lubricant. Grinding spindles with hybrid ceramics may run 4,000 hours without problems, compared to 3,000 hours with steel bearings. SKF reports running hybrid bearings up to 5,000 hours at speeds exceeding 2.0 million ndm before part degradation occurs. (Ndm is the bearing pitch diameter in millimeters multiplied by rpm, a value that compares the relative performance of bearings of different sizes.) Some steel bearings quit after 700 hours. Hybrid ceramic bearings can lower temperatures nearly 50 percent and last as many as seven times longer than steel bearings. In a horizontal machining center, switching from steel to hybrid bearings has been shown to drop bearing temperature from 60°C to 36°C at 12,000 rpm.

Belt Drives Can Be Hip, Too

Conventional belt-driven spindles, which use a pair of angular contact bearings at the belt-drive end, may have problems with spindle deflection and premature failures. At high speeds, the belt pull loads the bearings radially and also restricts the axial movement of the bearings to compensate for the thermal growth of the spindle system. In a typical hybrid ceramic roller bearing upgrade for a 40-taper vertical machining spindle operating at 15,000 rpm, the rear bearing set is a single row hybrid ceramic roller bearing with a composite plastic cage while the front bearings may be triplex angular contact hybrid ceramic ball bearings. Lubrication is synthetic grease. The hybrid ceramic roller bearing offers twice the radial rigidity as the original angular contact set and allows for smooth shaft thermal elongation. The operating performance of the cylindrical roller bearing with grease may be as high as 1,162,500 ndm at a temperature of 36°C.

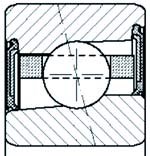

Shielded Is Faster

Upgrading to shielded ball bearings can eliminate the need for air purge or spot oil lubrication while reducing contamination and allowing increased spindle speed. Standard shielded bearings have the same internal geometry, ball diameter, speed rating, load ratings, preload classes, matching criteria and contact angles as the bearings they replace.

Double-shielded bearings are dependent solely upon the pre-packed lubricant of the bearing. An SKF high speed double-shielded design incorporates smaller diameter rolling elements. Its rings have been designed with open conformities for high speed performance. This design has higher speed capability but lower load ratings than the corresponding size of the standard bearing. These high speed shielded grease bearings will run faster than spot oil lubricated standard bearings.

Let The "Force" Seal It

Air seals are available from a few manufacturers. Air seals, such as those from Gilman, use an air distribution ring and a rotating metal cased elastic sealing member combining the advantages of contact seals and air purge. The elastic sealing member slightly lifts from the contact surface as the spindle rotation increases the centrifugal force. The metal case slings away any oncoming contaminants. The air-distribution ring allows for uniform airflow, which ensures that the seal will ride on a thin film of air while rotating. The air also pushes contaminants away from the spindle. In a static condition, the elastic seal provides a positive contact by keeping contaminants from entering the spindle.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)