German Precision Tool Industry Projects Decline in Consumption

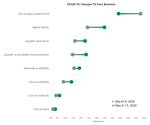

The economic impact of the coronavirus is predicted to draw a negative effect on Germany’s precision tools industry in 2020.

Manufacturers of precision tools are increasingly feeling the effects of the coronavirus pandemic as it inevitably continues to spread worldwide and break supply chains. According to the German VDMA Precision Tools Association, demand for cutting tools, clamping technology and toolmaking is decreasing significantly as a result of the measures to fight the pandemic. Since most car makers put brakes on European production, the whole supply chain has been affected, says Chairman Stefan Zecha.

The German precision tools industry is facing a rocky road ahead.

“Our forecast for 2020 that showed a 6% decrease in precision tools consumption is unfortunately no longer valid. We are currently facing the enormous challenge of ensuring our employees’, customers’ and business partners’ health, as well as keeping our companies liquid and running in the long term. Moreover, manufacturers of urgently needed parts for medical technology must continue to be supplied, especially now.”

According to Mr. Zecha, most precision tool companies still are currently able to deliver because they have set up their value chains in a crisis-proof manner. However, not all companies will be able to bridge the gap until the global economy recovers. Therefore, short-time work is now indispensable for many tool manufacturers. (Through the short-time work scheme, the government partly replaces an employee’s lost income from reduced working hours — in the most extreme cases, all the way down to zero hours — if the business does not lay off the employee.)

While the cutting and clamping tools sector was still able to produce at a high level last year, a large part of the toolmaking industry has been struggling with a weak order situation for some time now. Many toolvand die makers in the automotive supply chain have been running on empty for about a year now, since customers were reluctant to place orders in view of weaker demand from abroad, stricter emission rules and electrification.

"My appeal to politicians and financial institutions is to act quickly to keep the economy running during the coronavirus crisis. Jobs are attached to every single order and, in the case of medical technology applications, often the life of a sick person," Mr. Zecha says.

.png;maxWidth=300;quality=90)