Haimer Shrink Fit Toolholders Raise Boulevard's Feed Rates

Haimer’s Inductive Shrink Fit technology provides efficiency benefits over side-lock and collet holders, with Boulevard Machine & Gear seeing its feed rates more than double on certain materials.

Haimer’s inductive shrink fit technology has more than doubled Boulevard’s feed rates with certain materials, while also maintaining a higher rigidity than the shop’s old equipment.

Boulevard Machine & Gear is a family-owned gear cutting shop in the Pioneer Valley of Massachusetts serving the aerospace and defense industries. In 2006, Susan Kasa acquired the company and began implementing plans to increase Boulevard Machine & Gear’s efficiency.

Complicating Kasa’s focus on growth and efficiency was an observation from several of the shop’s machinists, who determined that they would run into issues completing certain jobs with the shop’s conventional side-lock and collet holders. Tool holding became a priority for Kasa as she started investing 20-30% of revenue into modernization and innovation of the shop. Boulevard Machine reached out to Jim Roberts, sales engineer at Lindco Springfield, to see if he could guide them to a solution.

Expanding Versatility With Shrink Fit

“Boulevard wanted to run more accurately and extend tool life,” Roberts says. “I immediately recommended Boulevard take a look at the Haimer product offering.”

After seeing Haimer’s tooling firsthand, Boulevard Machine decided to invest in a Haimer Power Clamp Special Edition shrink fit machine, Standard Shrink chucks and Power Shrink chucks and extensions.

Haimer specializes in inductive shrink fit technology for tool holders. The company says its technology’s high gripping torque and 360-degree clamping around the cutting tool provides superior gripping torque while allowing for reduced runout, balance repeatability and clamping consistency.

“We've had extensions stacked into Haimer basic holders with more than 10" of projection and as little as 0.0002" runout,” says Kristian Kasa, CNC programmer at Boulevard Machine.

Swift, Stable Results

Boulevard Machine now has a wide assortment of CAT40 and HSK-63 holders in both Power and Standard Shrink, as well as a wide variety of extensions. Since switching to the heat shrink holders, Boulevard Machine says it has been able to pick up its feeds and speeds. One notable example stemmed from the 0.75" Haimer Ultra Short Power Shrink HSK-63 holder, which cut one material at 750" per minute where before the shop could only cut 300" per minute. The shop now says the holder is its go-to for roughing, and that the holder keeps projection lengths short — resulting in more rigidity than conventional side-lock or milling chucks.

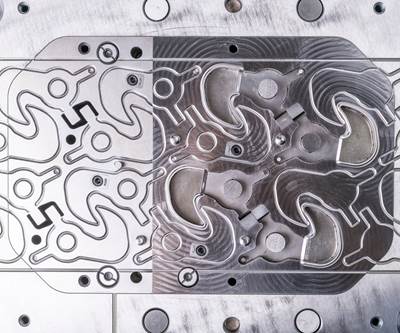

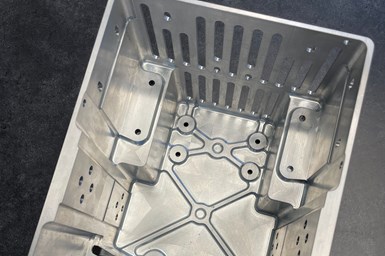

Difficult-to-machine parts like this billet 6061 aluminum block for an aerospace customer required the versatility and rigidity of Haimer’s holders and extensions to meet dimension, surface finish and tool life requirements.

Boulevard Machine & Gear now finds themselves doing as many five-axis jobs as they do three- or four-axis jobs. The Haimer Power Mini shrink fit holders and shrink fit extensions enable the shop to machine hard-to-reach areas without concern. This includes the interior of billet 6061 aluminum blocks for the aerospace industry, which Boulevard Machine work down to 10" × 7" × 7" before hollowing them out to a 0.125" wall thickness, with corner radii also at 0.125". ER holders could not reach the corners due to the nose of the holder, and side-lock holders produced too much runout to achieve the necessary surface finish and tool life. The Haimer Shrink holder and extensions were able to reach the corners, and the reduced runout maintained an even chipload to improve surface finish and tool life.

“We've had extensions stacked into Haimer basic holders with more than 10" of projection and as little as 0.0002” runout," says Kristian Kasa, CNC programmer at Boulevard Machine. “Without these holders, we would not be able to machine a large amount of our jobs through our shop.”

“We work closely with our programmers and engineers to make sure that what we are implementing and using is making their jobs as easy and efficient as possible,” Susan Kasa says. “Between having the Haimer technology and staying up-to-date with everything else, our team is no longer hesitant about quoting or taking jobs, and they have the confidence to do any task because of the sophisticated technology.”

Related Content

T.J. Davies Retention Knobs Maximize Cutting Tool Life

Custom-made retention knobs are sized to fit the machine tool and spindle or toolholder to extend the life of existing machine tool assets.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreBig Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

Read MoreRead Next

Choosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreCutting Tool Technology Aids Lights-Out Machining Applications

These features can help improve cutting tool stability, standardize cutting performance and extend tool life, enabling shops to confidently run unattended shifts.

Read MoreHard Milling Replaces Hand Grinding in Finishing Die Components

A focus on repeatability, geometric capabilities and speed led this manufacturer of fine-blanking machines and components to embrace hard milling as its go-to finishing process, eliminating hand grinding.

Read More

.png;maxWidth=300;quality=90)