Harnessing the Holding Force

Inserts engineered to augment the vise’s effectiveness allow work to be held rigidly on a tiny clamping area.

Milling and turning inserts have the shapes they do because the insert’s geometry affects chip formation, thereby affecting the performance of the cut. Insert forms are strategically designed to direct cutting forces in the most effective way.

Could inserts also be strategically designed to direct the force of workholding?

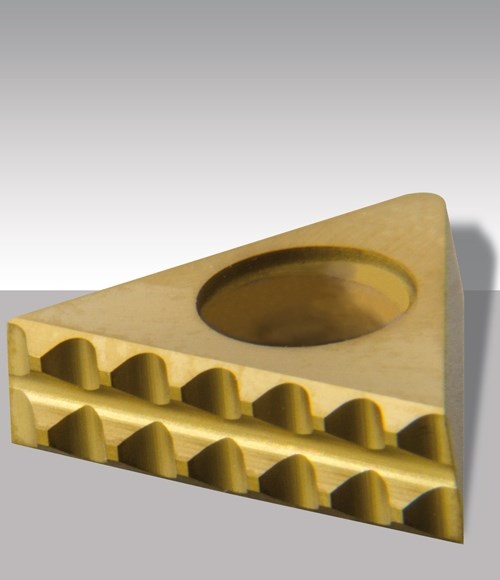

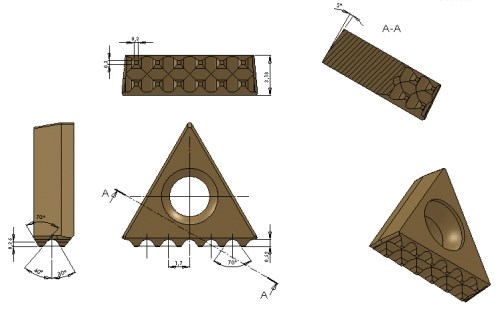

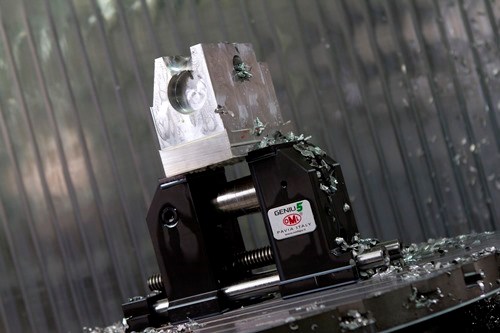

That is the idea behind the “SinterGrip” vise jaws from OML, which use carbide inserts to grip the work. Each serrated insert slightly penetrates the work, while also featuring an engineered form that directs clamping force in a way that improves the vise’s hold on the workpiece. The result is rigid clamping from a system that holds only a tiny edge of the part—just 3.5 millimeters. One of the most important benefits of achieving the secure hold on this small region is more productive five-axis machining.

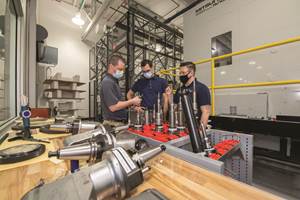

Lexair supplies the vise jaw system (see Editor’s Note). Steve Breslin, national sales manager for Lexair, describes the connection to five-axis machining. Part of the value of five axes is the chance to machine various faces of the part in a single cycle, he says, but this inherently means that those faces have to be exposed for machining. Clamping on a small area, to get the workholding out the way, typically translates to low holding force. Thus, five-axis machining frequently ends up being delicate machining.

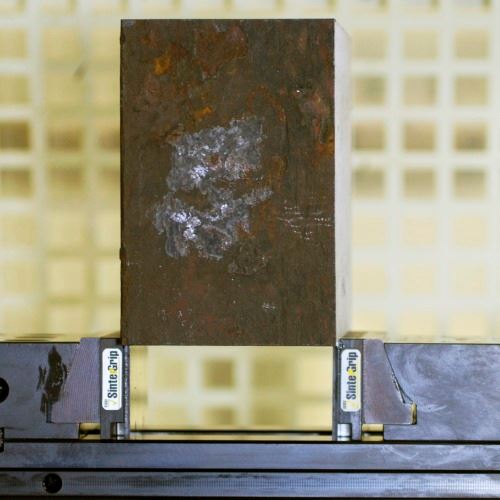

By contrast, the video above of heavy milling in steel illustrates the cutting that is possible using this same small clamping area. The SinterGrip inserted jaws achieve the strong hold for this heavy milling in various ways.

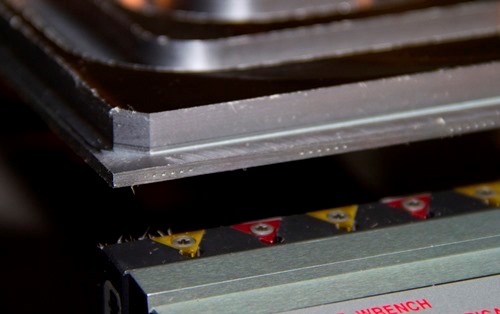

The hold partly comes from penetration. The serrated inserts slightly press into the part upon clamping, to a depth of no more than 0.5 mm (usually much less). In some applications, this impression provides an added benefit, because it creates location references for re-setting the work for re-machining.

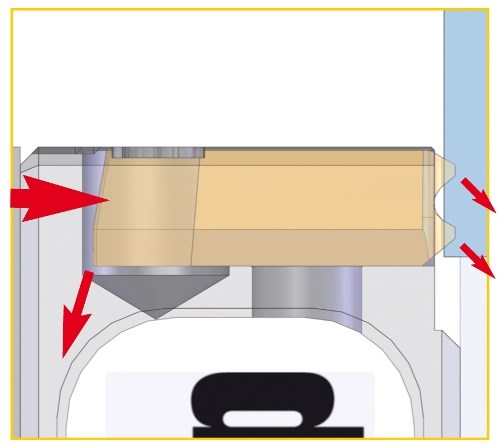

Another component of the rigid clamping is the insert’s form. Just like a cutting insert, the shape of this insert aims to channel forces to the process’s advantage. Different angles above and below the serrations produce a resultant force that directs the work downward toward the machine table. Negative angles on the insert faces that meet the pocket also produce a downward-directed force. These effects make better use of the vise’s holding force than straight jaw faces that simply direct the force into a squeeze applied parallel to the machine table.

The inserts come with parallels as part of a jaw system that can be installed on most mechanical or hydraulic vises. Different clamping inserts are designed for different part materials, varying in the number and design of serrations, as well as in the coating applied to the insert. For holding standard steel, the carbide inserts are coated with TiN, while inserts for aluminum are coated with CrN/NbN and inserts for titanium and hardened steels are coated with TiAlCn. Replacing worn inserts is easy, says Mr. Breslin—though he points out that since the inserts are holding the work instead of cutting it, there is no reason to expect that they will ever wear out.

Related Content

Choosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreBuilding a 5-Axis Cell

5-axis machining has taken over the metalworking industry, but what goes into a high-functioning 5-axis machining cell?

Read MoreDigital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)