Insert Provides Long Life, Short Cycle Times

Novatek, a manufacturer of diamond products used in the oil and gas, mining, construction and other industries, needed to reduce both costs and production time on a job involving very large workpieces. The Tiger-Tec black and gold WPP10 insert from Walter USA, which features an aluminum oxide coating designed to prolong tool life at high surface footages, helped the company increase feeds and speeds and create smaller, more manageable chips.

Management at Novatek, a Provo, Utah-based manufacturer of industrial diamond products, believes harnessing technological solutions to improve productivity is important to stay afloat in today’s global market. Faced with insert life and chip control problems that increased costs and cycle times, they knew such a solution was needed for the company to keep its competitive edge. With aluminum-oxide, Tiger-Tec, black and gold coated inserts from cutting tool manufacturer Walter USA, the company was able to drive down costs on its diamond-sintering equipment while maintaining consistency in its turning operations.

Novatek was founded in 1985 as a developer of new technology involving high pressure/high temperature (HP/HT), wear-resistant materials and related applications. Today, the company manufactures diamond products serving the oil and gas, asphalt, mining and construction industries. The company’s presses clarify natural diamonds and sinter synthetic diamonds. Many of its products incorporate industrial polycrystalline diamond (PCD), which has been used in the drilling industry for decades.

Having pinpointed cutting tools as a particularly problematic and costly facet of Novatek’s business, Jay Reynolds, senior production plant engineer, researched several suppliers to find a solution that would increase insert life and improve chip control on rough and finish turning operations. Based on a recommendation from a local distributor, Novatek invited Walter USA’s Curt Nicholson to test that company’s products on a difficult application.

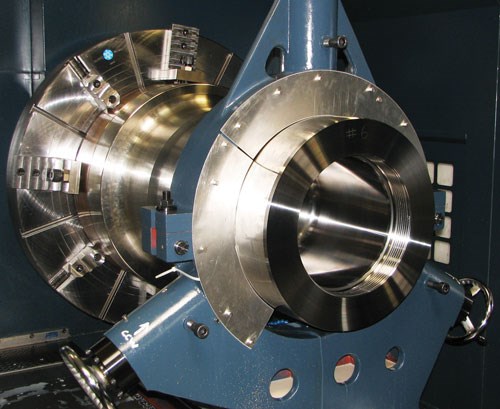

That application involves manufacturing six large cartridges for installation into a 400-ton diamond press. The cartridges are machined from 4340 FX-Xtra steel that is heat-treated to between 38 and 42 HRC. Two machines are used in the operation, a Johnford 60160G Super Turning Center and a Mori Seiki SL603CMC lathe. This is a big job—each cylinder weighs 12,500 pounds prior to any metal removal, for a total of 75,000 pounds of material in all six cylinders. Machining each cartridge to its final weight of 5,000 pounds requires removal of 7,500 pounds of steel, for a total of 30,000 pounds for all six parts.

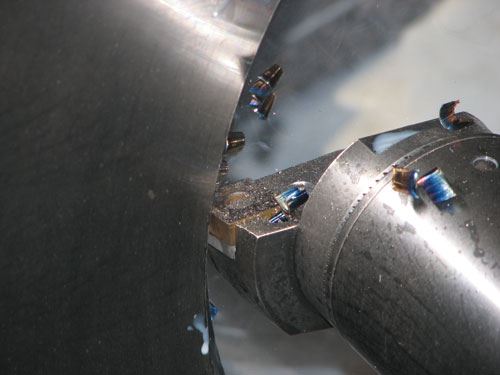

To maximize performance, Mr. Nicholson suggested using Walter’s Tiger-Tec CNMG 644 NM9 WPP10 insert. Running at 0.22 ipr and 225 sfm at a cutting depth of 1/2 inch, the insert removed 450 pounds of steel per hour, outperforming both the previously used insert and competitor inserts tested at Novatek.

Machinist Ryan Reynolds says he was "amazed" by the performance of the Tiger-Tec WPP10 in this application. In addition to providing the capability to quickly hog out a lot of material, insert life was much greater with the WPP10 than with the competition. Two other inserts the company had tested lasted for 12 and 7 inches per cutting edge, respectively. In contrast, the Walter insert lasted for two 36-inch cuts—a total of 72 inches—down the part’s OD before requiring rotation to a new cutting edge. The difference is even greater than it appears at first glance—while the company tested the WPP10 in a dry cut, it ran the other two inserts with coolant. With coolant, the Tiger-Tec WPP10 lasted for 144 inches per cutting edge.

These figures show that compared with the insert that lasted for 12 inches, the WPP10 provides an 833-percent improvement in insert life without coolant and a 920-percent improvement with coolant. Moreover, the insert’s NM9 chipbreaker creates smaller, more manageable chips, saving time for operators who were used to frequently emptying large, stringy chips from the chip dumpster. "Our previous, longer chips created problems in our conveyor during the removal process," Mr. Reynolds says. "With Walter’s insert, our chips are now short and tight."

Walter’s technical knowledge also contributed to Novatek’s success. The cutting tool supplier provided recommendations on proper speeds and feeds as well as how to achieve the desired chip. With the new inserts, the company cut the time it spent roughing the parts from 16 hours to 9 hours. Total time savings amounted to 30 hours for each cartridge.

Mr. Nicholson says the insert’s performance is largely due to Walter’s aluminum oxide Tiger-Tec coating, which is designed to prolong tool life at high surface footages. "The aluminum oxide layer allows heat to be pulled away from the chip, which results in longer life and shorter cycle times," he explains. "This adds up to significant cost savings for the user."

Related Content

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreTwin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)