Machine Monitoring Has a Lot to Learn

Supplementing CNC connections with sensors and machine learning enables predicting performance on the level of the individual part.

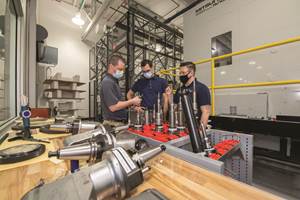

In the immediate term, the Datanomix/Caron partnership will provide joint customers with aggregate Caron system data for display in machine monitoring dashboards like the one seen here at Eptam Plastics, where team leader Jesse Bunnell (picture) has used machine monitoring to identify training gaps. Photo: Eptam Plastics.

Comparing your machine monitoring software to a fuzzy, 1980s-era television may not seem like a good sales strategy, but context matters. And in the context of a recent conversation with Greg McHale, co-founder and chief product officer at Datanomix, the analogy referred to a gap in the capability of virtually any machine monitoring system — a gap that he says is closing through the addition of data from sources beyond the CNC. The end game is moving from monitoring to automatic predictions of process performance (and perhaps even quality) at the level of the individual part.

“The gap is high-fidelity data that better characterizes the physical machining process,” McHale explains. “When it comes specifically to things like cutting tools and their health and their wear, and the harmonics and frequencies around spindle health, (monitoring via the CNC) is like a 1984 Zenith, where you need tinfoil in the antenna to get a signal.” Now, thanks to a new partnership with Caron Engineering, “there are no missing pixels.”

Caron Engineering has been fitting power, vibration and other such sensors to machine tools for nearly 35 years. These sensors provide higher-resolution data than the CNC can provide, even if the CNC offers the same information. Rob Caron, founder and president, cites the example of measuring horsepower consumption for the smallest cutting tools. “If there’s a 20-hp spindle on a machine tool, you get a 0- to 20-hp resolution when you pull the data from the machine control,” he explains. “Cutting with a small tool drawing 1 hp will barely show up.”

In contrast, Caron’s sensors are “infinitely scalable,” he continues. These sensitive horsepower measurements can feed systems like Tool Monitoring Adaptive Control (TMAC) to detect when a tool is working harder than it should to maintain the specified feed rate — an indicator that the cutting edge is breaking down — and then issue alerts or even adjust parameters to compensate for wear.

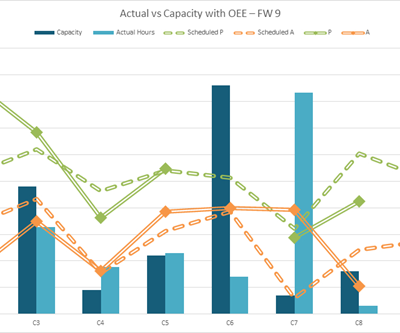

Datanomix’s machine monitoring software operates on a different scale. Its focus is plant-wide cycle times, utilization rates and metrics like overall equipment effectiveness. This work does not require high-resolution sensor data, McHale says. Likewise, macro-level data is not required for his new partner Caron’s systems to essentially “run a machine better than it runs itself.” A manufacturer could conceivably install TMAC independently, then watch Datanomix numbers tick up as productivity improves.

What, then, is the need for further integration? What, exactly, does McHale’s “4k UHD” (ultra-high definition) picture look like?

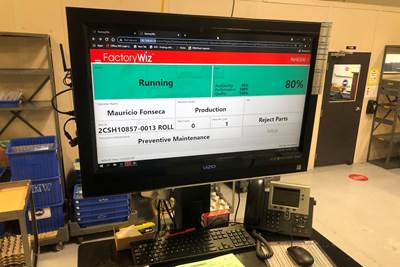

The most immediate benefit of aggregating Caron’s localized data into Datanomix’s cloud-based analytics engine is visualization, he says. The monitoring software now features the status of every TMAC-enabled machine in a plant, including not just tool wear information, but also the health of the machine’s spindle bearings.

“The waters are muddied by everyone selling bits and pieces, but they’re not tying it together.” – Rob Caron, Caron Engineering

However, new dashboards merely tease at the potential benefits that Caron says he can envision with the machine learning algorithms that drive Datanomix’s analytics engine. “We have so much information on a per-machine basis, but we need to tie it all together and look at new ways of finding problems and anomalies,” he says. One potential example involves data from the company’s ToolConnect system, which uses data from the presetting equipment that measures tool assemblies to update offset, identification and other information in the CNC. “If you hold a tool (assembly) to a tighter tolerance, what happens downstream, with surface finish and dimensional data?” he asks hypothetically. “Do you get a better result?”

Datanomix is ideal for such analysis because the system’s output is organized primarily around individual part numbers, McHale says. Specifically, the system sets and dynamically adjusts a specific productivity benchmark (in the form of a letter grade) for each new job as the job runs. Supplementing this information with sensor data could not only improve the benchmark directly, but also unlock capabilities like predicting tool consumption and costs (or, with the right sensors, coolant consumption and costs) at the level of the individual job as well. “For instance,” he explains, “I want to understand exactly how many cycles, how many cutting hours — how much work I’ll get out of each tool on each part number that I have, based on real performance data. I want to predict what real tool life will be for each part I make, my tooling consumption and how that plays into my tooling cost.”

In fact, he says the engineers that develop Datanomix’s machine learning algorithms are “salivating” about new possibilities. One example is predictions of part quality. For example, with sufficiently granular data to characterize virtually every tool an every cut, the company could potentially link even the most minute changes with downstream part geometry changes, thereby identifying specific dimensions as being particularly worthy of inspection. “With this partnership, we are declaring our intention to be co-collaborators on solving higher-level problems that neither of us can solve alone,” he says.

Caron agrees. “We’ve been able to provide this same data for 35 years now, but when the customer doesn’t need to look at any data, when the system says ‘I see something wrong because I’m pulling data from all these different places and applying machine learning’ — that’s when Industry 4.0 becomes something real,” he concludes. “Today the waters are muddied by everyone selling bits and pieces, but they’re not tying it together.”

Related Content

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreDigital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read MoreShop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

Read MoreShop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read MoreRead Next

Adding Part Traceability to CNC Machine Monitoring

Focusing on what makes money puts CNC machine monitoring data in context.

Read MoreMonitoring Machine Tools? Don’t Discount DNC

Networks that feed part programs to shopfloor CNCs can double as a foundation for pulling data from them.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)