Machining for Air Quality

Honing experts describe the significance of this machining process for meeting the most recent emissions standards affecting cars, trucks and other vehicles.

Makers of all types of engines have been under pressure for decades to reduce emissions. And for decades, they have done so. Not just car and truck makers, but also makers of engines for vehicles ranging from lawn mowers to locomotives—all have improved fuel efficiency and air-pollution performance to meet increasingly tighter government standards. Today, though, the difference is not just a matter of degree, but also a matter of difficulty. Engines are now so efficient that their designers have to work that much harder to obtain further incremental efficiency gains.

Two witnesses to this are Dennis Westhoff and Rich Moellenberg with Sunnen, a company that specializes in bore honing systems and tooling. Perhaps more than any other machining process, honing is particularly important to the search for tighter engine-emissions performance.

“In the 1980s, all the easier stuff was done,” says Mr. Westhoff, Sunnen’s global business development manager. Straightforward improvements were made to vehicle engine designs that originally had not treated fuel efficiency or air quality as paramount concerns. The history of meeting emissions standards proceeded from these mechanical refinements to improved form and dimensional tolerances resulting from better machining, including improved accuracies for cylinder bore roundness and cylindricity. Now, engine makers seeking further refinements look to even more minute levels to meet current emissions requirements. Specifically, opportunities for winning greater engine performance today tend to focus not on dimensional form tolerances, but on the even smaller surface-finish characteristics of piston, injector and fuel pump bores. Honing is perhaps uniquely suited among machining process for repeatably achieving a desired finish on these bore IDs.

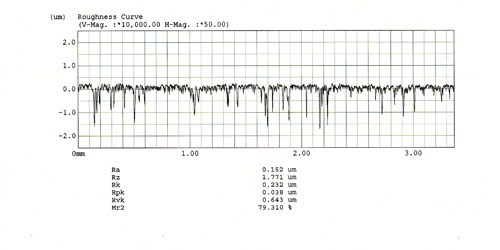

Mr. Moellenberg, the company’s manager of system sales, says those modern engine-system surfaces are specified in ways that go well beyond the “Ra” (average roughness) commonly used to describe finishes. Parameters from the “Rk” family, for example, describe microscopic attributes including the surface’s bearing-area curve and its peak height under load, as well as the capacity of troughs in the surface to retain oil. In honing, the selection of stones and equipment—as well as the programmed motion and the sequence of separate honing operations—can be tailored to generate precisely the surface that might be specified by an engine company’s tribologist (or specialist in interacting surfaces).

Holding Oil

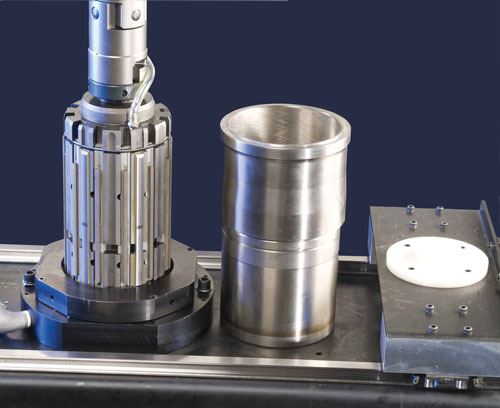

Honing, for bores, is a process in which an expanding tool assembly with abrasive stones rotates inside the bore, while the tool or part reciprocates. Because the cutting points of the honing abrasive are small and numerous, the heat and stress produced in the workpiece are small. An outcome characteristic of honing is a crosshatch pattern that facilitates lubrication transfer along the length of the bore. This crosshatch pattern is another aspect of honing that can be precisely controlled.

Lubrication transfer is one of the principal areas in which a cylinder surface might be designed for improved emissions performance. Along the bore ID, if the surface itself can help to use oil efficiently and let it spread more easily, then less oil will be needed in the cylinder. That means less oil will burn as the engine runs. “As much as possible, the goal is to get the cylinder dried up,” Mr. Moellenberg says.

However, another goal in surface design is to reduce sliding friction—and this goal might compete with oil transfer. A surface that is “smoother” in terms of sliding friction might be less effective at retaining and transferring even quantities of oil. Tribologists and other engine specialists seek to realize the right balance between aims such as these. The resulting surface design is often complex, characterized by various surface-finish parameters with exacting meanings. The honing technology provider might then spend months developing a process to achieve this surface and proving that process for high-volume production.

“They know what surface they want, but not how to machine it,” Mr. Westhoff says. In fact, he says the early stages of discussing a new process sometimes reveal that, from a machining perspective, certain surface callouts are mutually contradictory and cannot both be achieved.

Honing Under Load

Beyond these surface characteristics, other capabilities of honing—including controlling dimensions such as bore size, roundness and taper—also remain important, he says. If manufacturing devotes less attention to these parameters today, that is only because they have long been tightly controlled in engine-related machining. However, in the pursuit of greater fuel efficiency, tolerances in these areas are getting tighter as well, with clearances between moving parts shrinking micron by micron. One result that Sunnen sees is that practices from performance race car engine making are migrating into conventional automotive engine production.

An example Mr. Moellenberg cites is torque-plate honing, in which torque is applied to a cylinder to simulate the cylinder’s eventual assembly into the engine block. The cylinder is honed in this loaded condition. The reason for machining in this state relates to how small clearance dimensions between moving parts have become. The specified fit between the piston and cylinder might now be so tight, he says, that just the tiny distortion of the cylinder resulting from its fit in the engine could prevent the piston from functioning.

Related Content

Ford Partners With Rockwell Automation to Advance EV Program

The companies will jointly collaborate on assembly tooling designs and architectures that will increase speed to market.

Read MoreEliminating Automotive Defects Per Million With Automated Visual Inspection

This automotive manufacturer virtually eliminated PPM defect complaints after implementing an automated visual inspection system at its facility.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreElectric Vehicles Spark Bright Ideas

Ford alone expects to have production capacity for 600,000 electric vehicles by late 2023, and more than 2 million by the end of 2026. The effects on manufacturing are BIG.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)