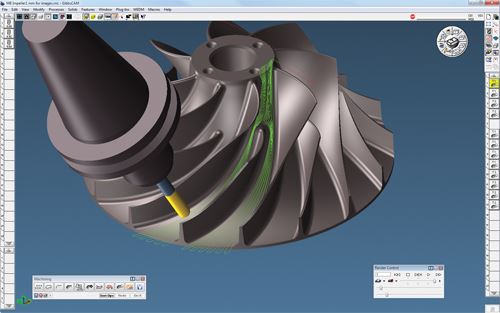

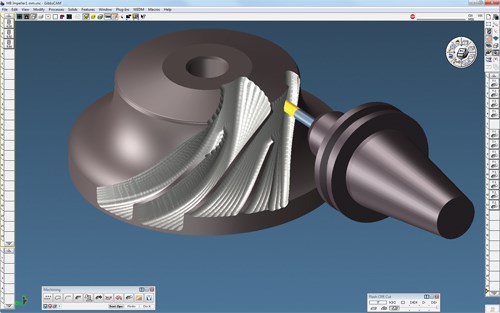

Turbo-machinery parts such as blisks or impellers are often depicted as the epitome of simultaneous five-axis machining. The spiraling blades spaced closely around a hub create complex curves that can be machined only with a twisting, swiveling motion of a slender cutting tool. Maneuvering a cutting tool in such intricate moves requires a machine capable of actuating five axes at once in a coordinated fashion.

CAM software that can generate toolpath programs for parts requiring five-axis motion has become more powerful and easier to use. This development has made five-axis CNC machines more practical and productive. Gibbs and Associates (Moorpark, California) has taken another step to make it easier for CNC programmers to create five-axis tool paths for machining blisks, impellers and similar turbo-machinery parts. The timing seems appropriate because this kind of work is one segment of the machining industry that is expanding.

A new option called “5-Axis MultiBlade,” complements the larger five-axis programming package in the company’s

GibbsCAM product line. Essentially, MultiBlade arranges and formats the software features of the five-axis package to focus specifically on making the programming of blisks, impellers and similar workpieces more intuitive and convenient. For example, the user interface uses common turbo-machinery terminology. Programmers are prompted to select predetermined features that are specific to turbo-machinery parts, such as hubs, blades, shrouds, splitters, fillets and so on. These are the same names given to these features in the part’s CAD file. In turn, MultiBlade provides interface items corresponding to these specific types of features. The associated machining strategies are likewise optimized.

Demand for this kind of specialized programming is increasing because of two concurrent trends. One is the tendency to combine components into a single piece to reduce weight, streamline assembly and increase strength. Parts that were once produced with a separate hub and individual vanes or blades are now being machined from a solid billet or large casting. Another is the proliferation of products that require blisks or similar vaned components. Once mainly represented by jet engines and hydroelectric turbines, one-piece, multi-bladed components are now found in other aerospace products as well as compressors, power generators, pumps and automotive turbochargers.

Software specialized for turbo-machinery parts will ease the burden on programming departments and help meet the need for programmers with these critical skills. For its part, Gibbs says the machining strategies provided by MultiBlade can make programmers more productive. For example, roughing and blade finishing routines include options to offset layers from the hub, from the shroud or from a blending between them. In addition, tilt controls enable programmers to define lead and side tilt, as well as clearances between the tool assembly and the workpiece. Likewise, programmers have options for toolpath extension at the leading and trailing edges, both tangential and radial, with leading and trailing edge tool control. Another handy feature is the ability to automatically copy and rotate toolpaths around the part. For example, the programmer can simply enter the number of blades required for a given part, along with a few variables, and the software will evenly space the machining routines to generate the entire set. Gouge checking is then applied to the compiled chain of tool paths.

Because MultiBlade is an option within the GibbsCAM 5-Axis package, postprocessors are available for all of the five-axis machining centers and multitasking machines in the company’s library. Likewise, all of the models in GibbsCAM Machine Simulation library are available to check for errors or tool interference. An advanced version of MultiBlade provides additional capabilities.

.png;maxWidth=300;quality=90)