Manufacturing Touches Lives, Now More Than Ever

History shows that crises like the coronavirus pandemic can produce exceptional human efforts on a global scale. Is your shop participating?

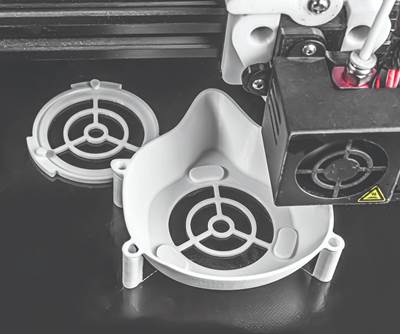

New masks, new challenges, same team at the Pioneer Service machine shop. The shop has shifted to making precision parts for ventilators, stretchers and biotech equipment in response to COVID-19 demand.

Like wars and natural disasters, the coronavirus represents an unwelcome crisis that will have long-lasting effects on the global economy and, most importantly, the lives of our loved ones. However, if history has taught us anything, it has taught us that such events can produce exceptional human efforts on a global scale. It is our time to shine.

Manufacturing has a huge part to play in this effort. Demand for parts for ventilators, stretchers and other biomedical essentials is some six times greater than normal and expected to continue for the next several months. During these lean times, Pioneer Service is only one of many manufacturers that are grateful for the opportunity to contribute and keep their doors open to do so.

All the talk about Industry 4.0, digital transformation and continuous improvement is paying off as we ramp up to meet unprecedented demand for medical device parts. The process of retooling our equipment hasn’t been easy, but the power of real-time data has helped. Few would claim the transition is anything close to plug-and-play, but standardized tooling and training makes the transition substantially less painful.

We’re fulfilling an essential need, but it’s not exactly lucrative (nor should it be). While I believe the industry will emerge stronger, the reality is that some manufacturers will still go under. In some ways, it’s the Great Recession all over again. Across manufacturing, long-time customers have closed their doors or simply put their orders on hold. The ones remaining, many of whom are in the medical sector, are counting on us to deliver desperately needed parts, but this need alone won’t solve cash-flow challenges for most businesses.

This disruption is not a problem unique to our industry. We are not martyrs. If anything, we’re at an advantage because we’re in the position to simultaneously safeguard the needs of our community and the livelihood of our employees. The challenge is finding the balance point between the two, even and especially when it’s hardest to do so. Many of us facing this challenge feel overwhelmed, and for good reason. There’s no manual for “How to Protect Employees, Contribute to the Greater Good, and Stay in Business at the Same Time.” My answer is: I’m making it up as I go, but doing the best that I can. This is not a blemish-free effort, but this is our chance to create a company culture that spans generations.

It might be cheaper and easier to just close up shop, but are we ready to lay off our people because business is inconsistent? Or are we ready to stick it out? I’m proud to be part of an industry that is, for the most part, striving for the latter. Our solution doesn’t need to be perfect, and we’re sure to make mistakes, but the point is that we’re trying.

Financial support is understandably at the top of most employees’ concerns. Even so, many companies are taking extra steps to show that they care. This means little gestures, like sending them home with sanitizers, disinfectants and masks because the store shelves are empty. It means rotating toilet paper donations among the employees. It means having conversations about their concerns and well-being, asking about their families and child care, and following up with them in the coming days and weeks.

Through the Precision Machined Products Association (PMPA), I know many companies are offering discounted lunches from local restaurants. The restaurants appreciate the business, and it eases employees’ financial burden while filling their bellies. Other manufacturers are providing Grubhub gift cards to local firefighters and police, or sending volunteers to work at local food banks.

As terrible as COVID-19 is, I cannot help but marvel at the industry-wide effort to fight for the greater good. Companies overwhelmed with ventilator part requests are sending those requests to former competitors. When one PMPA member company was facing a production stoppage due to a missing gage, multiple competitors offered to send them the tool to keep production rolling. How often does that happen, in any industry? This is evidence that #StrongerTogether is more than just a pretty hashtag.

One day soon, this pandemic will pass. If manufacturing is truly about touching lives, then what will remain are the promises we kept to our employees and the satisfaction that we fought this pandemic together. Decades from now, when we revisit this historic event, perhaps we’ll also remember how we were united in our resolve to show the very best of what humanity has to offer. Not profit, but compassion. Not politics, but unity. Not fear, but resilience. This too shall pass, and we’ll be more ready for the next challenge because of it.

About the Author

Aneesa Muthana

Aneesa Muthana is co-owner, CEO and president of Pioneer Service Inc., a Certified Women-Owned Small Business contract manufacturer specializing in Swiss precision parts, CNC turned parts and centerless grinding services in Addison, Illinois.

Related Content

View From My Shop, Episode 2: 3D Printing and Postprocessing With Tangible Solutions

Collaboration between Tangible Solutions’ additive and machining departments simplifies their work. Learn more in this episode of The View From My Shop.

Read MoreYCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Read MoreBeyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreFive-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

Read MoreRead Next

Which Kind of "More So" Are You?

The coronavirus pandemic has brought many people, businesses and industries to a standstill. How are you reacting?

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)