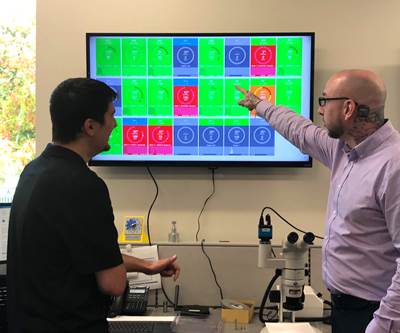

OPS uses information from machine monitoring systems and CNC programs to tell operators where to go within their cell at any given time. This information helps operators increase the productivity of their cells and manage more machines at once.

When shops first implement a machine monitoring system, it’s not uncommon for them to discover their machine uptime is lower than they thought. “All machine monitoring solutions out there show you how bad the production is because you collect data. You know that you’re at like, 40% uptime, but you don't know how to improve,” says Frederic Scherer, CEO of JITBase (Montreal, Quebec, Canada), a machine monitoring solutions provider. Shops are usually on their own when it comes to using this data to increase uptime. However, JITBase has devised a way to use machine data to create a clear map for shops to increase production.

Making the Most of Machine Data

Scherer says the idea for the product came from one of JITBase’s customers, an aerospace manufacturer that makes landing gear components with cycle times that range to 24 hours. “What they realized is that 80% of the time they had one machinist that is behind the machine and is just waiting for the machine to do the job,” Scherer says. “It was independent production from 80 to 90% of the time. The operator was waiting, doing nothing.” The customer asked him if JITBase could use the data it was collecting to help its machinists manage more machines. Scherer said yes, and as he thought about it, he realized this solution could help address the shortage of skilled manufacturing workers many areas are facing.

“It’s really like a GPS,” Scherer explains.

The resulting product, called Optimal Path System (OPS), uses machine monitoring and CNC programs to calculate the most efficient path for machine operators to take across the shop floor during their shifts, and displays it for operators via a tablet or other screen. “It's really like a GPS,” Scherer explains. “The vision is really to have one machinist in a cell of a few machines. It could be from three to six machines, and the machinist is able to manage efficiently all machines.”

Although the system is based around the concept of machine cells, OPS is flexible. Operators can choose which machines they’ll be running, even if they’re in different cells. According to Scherer, this is especially helpful for shops that have night shifts, when fewer employees are on the shop floor.

OPS is suited to several types of shops. These include manufacturers that produce parts with long cycle times (like the first customer, whose cycle times ranged from two to 24 hours) to medium cycle times (in the 30-minute range). Shops that produce parts with short cycle times can also use OPS if the machines are automated (for example, lathes with bar feeders). Scherer says the only shops that won’t be able to take advantage of OPS are ones that do a wide variety of parts with short cycle times (custom work or prototypes, for example).

Calculating the Optimal Path

The first step to implementing OPS is to implement a machine monitoring system. JITBase offers a machine monitoring program for shops that don’t already have one, but for businesses that already have a system in place, OPS can use data from any machine monitoring program. OPS uses this live data to gather information on the status of the machines (whether they’re active, interrupted, stopped, etc.) and spindle load. It updates every 10 seconds and sends alarms to operators if, for example, the spindle load is too high, indicating an issue that an operator needs to address.

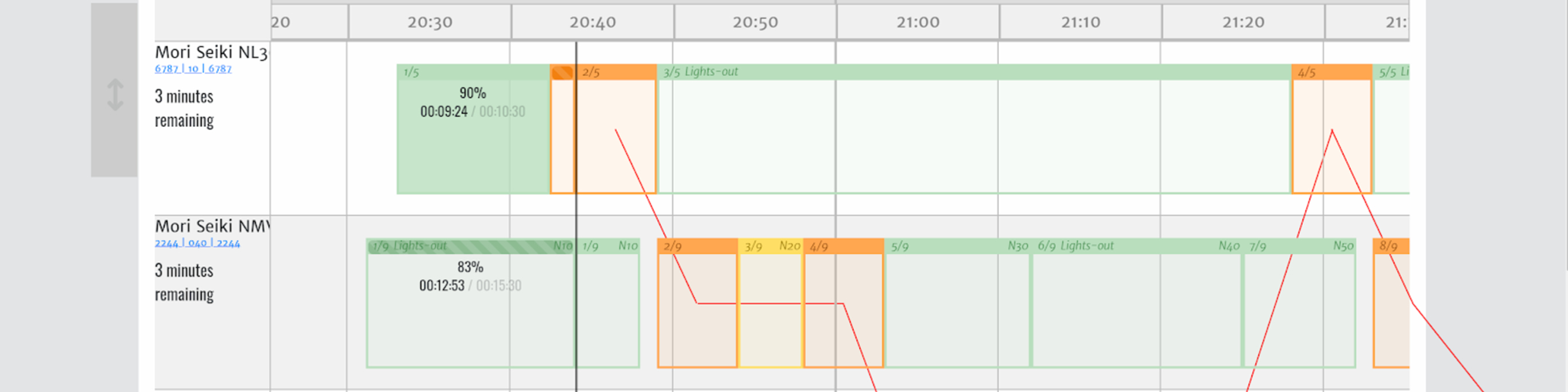

The system also looks at the CNC programs to determine where the periods of uninterrupted machining time, planned stops and program ends are. This enables OPS to create work plans for every program, which show when operators need to be at the machine (for example, to perform a manual inspection or unload a finished part and reload the machine), and when they don’t.

OPS uses the information from these two sources to categorize machines into

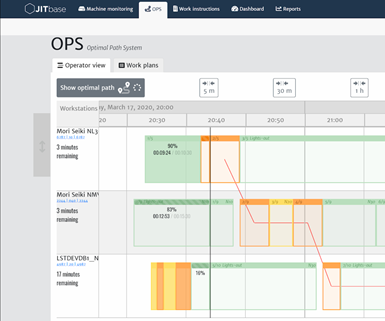

OPS creates a work plan for every machine program, which shows lights-out machining time (when the operator doesn’t have to be at the machine), planned stops (when the operator needs to be at the machine to do something) and stay on machine time (when the operators don’t have time to do something else before they need to return to the machine, or when the machine is performing a critical operation).

one of three states when a program is running. “Lights Out” means the operator doesn’t need to be at the machine. “Planned Stop” means the machine isn’t running and requires attention from the operator, and “Stay on Machine” means that the machine is running but the operator needs to be there (for example, if the cycle time is so short that the operator doesn’t have time to go somewhere else, or the machine is performing a critical operation). If there is an unplanned stop (for example, if the machine stops during an unfinished lights-out operation), OPS will alert the operator that there is a problem.

Looking Ahead

OPS also uses algorithms to calculate the best path for operators to take from machine to machine during their shift. According to Scherer, this decision isn’t always clear to operators. For example, it may be a machinist’s instinct to go to the first machine that stops, but this isn’t always the most efficient path. If a machine stops and the operator has to spend awhile there getting it running again (performing a manual inspection, unloading/loading the machine, etc.), other machines in the cell may stop during this time. These machines are being held up while the operator works on the first machine, especially if they only require a few minutes of the operator’s time. By looking ahead at the programs for all the machines in the cell, OPS can tell the operator which machine to go to first to keep the cell as productive as possible.

OPS can also help operators plan their breaks efficiently. Sometimes a machine stops five minutes after an operator goes on break and is down for the rest of the hour until the operator returns from lunch. “But if you see the future, you can actually see that in five minutes the machine is going to stop,” Scherer says. If machinists can see when they need to be at their machines and when they don’t, they can plan to take their breaks during periods of lights-out machining, increasing their productivity. “That's a really simple example but we truly see that it is a pattern,” he adds.

OPS Beyond the Shop Floor

The supervisor view in OPS shows machine progress and performance, as well as the initial and revised estimation of completion times. This enables supervisors to see when jobs are falling behind and adjust accordingly.

OPS isn’t just for machinists. The system also has a “supervisor view” that provides information on machine progress and performance, as well as the time a job was initially expected to be completed and the revised completion time, which takes into account unplanned stops. Because it’s tracking in real time, supervisors can see if projects are falling behind and adjust schedules accordingly.

Programmers can also use the work plans to increase efficiency. “It provides a kind of feedback on the programs that are created,” Scherer explains. “You really want to maximize that and have 90% of your CNC programs be lights out.” Programmers can optimize machine programs in a number of ways, including combining planned stops so the operator doesn’t have to continually return to the machine, or eliminating planned stops, for example by changing the tool that’s used for an operation so the program doesn’t have to stop for the machinist to change the tool.

Results

Scherer says OPS primarily impacts two metrics:

- Machine uptime. “The operator is more proactive because he knows exactly where to go next,” Scherer explains. “And because of the algorithm, it's the optimal path.” He adds that if operators follow the optimal paths the system lays out, shops can expect to see a 15 to 20% increase in uptime.

- Number of machines per operator. According to Scherer, this metric is related to machine uptime, because if operators are more proactive and know exactly where to go, they can manage more machines at the same time. The improvement shops could see on this KPI depends on the cycle times of the parts they run. “If the cycle time is in hours, it can go to four or five machines for one operator,” Scherer says. “If it's more like a 30-minute cycle time, you can go to three or four machines for one operator.”

Once shops implement OPS, they can expect to start seeing these results very quickly, within three months, Scherer says. “With OPS, as soon as you have the system, the operator is going to follow the optimal path and they directly improve the productivity,” he adds. “It's really super fast.”

Related Content

Beyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreReinventing a Precision Shop With a Data-Driven Mindset

When this machine shop lost 90% of its business within three months, a reinvention was in order. Here's how it survived after quickly falling on hard times.

Read MoreRead Next

Communication Clears Machine Monitoring's Morale Hurdles

When pen-and-paper methods of tracking job efficiency left AccuRounds’ engineers and managers in the dark, the shop switched to MachineMetrics. But machine monitoring brought morale challenges along with it.

Read MoreVideo: The Impact of Artificial Intelligence (AI) on Manufacturing and Machining

The machine tool monitoring that many CNC machining facilities are doing today could be a first step toward their use of machine learning. In this conversation, MMS’s “Data Matters” columnist Matt Danford speculates on the coming role of AI for refining machining processes.

Read MoreCNC Data Unleashes Shop Management System

Machine monitoring evolves from a progress-tracking tool to a foundational element of quoting, scheduling and process planning.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)