MMS Looks Back: 1980s - CAD/CAM Comes on Strong

As CNC machine tools displaced conventional, manually operated machines, computerized systems were taking over other manufacturing functions. This story is part of our 90th anniversary series.

The development of the computer numerical control (CNC) machining center in the late 1970s signaled the total eclipse of the manual machine tool in the following decade. Very few shops would still rely on standard, “conventional” machines for anything but toolroom work by the end of the 1980s. However, the rise of the computerized machine tool marked an even broader shift in machine shop operations. Computerization came to a wide range of other manufacturing functions (“applications” as we refer to them now) on the shop floor and in the front office. This shift represented two fundamental changes for almost all shops and plants reading this magazine.

One: For the first time, running the manufacturing business and running the production machines would be influenced by a single, powerful technological advance—the personal computer (PC), which was often called a microcomputer around that time. Two: Also for the first time, our industry would be dependent on advances coming from outside the metalworking or manufacturing world. General hardware and software developers such as IBM and Apple Inc. were in the lead, while applications for industrial design and manufacturing followed closely in response. The umbrella term for these applications was clearly “CAD/CAM,” but CAD/CAM was essentially a collection of specific uses for digital technology that was otherwise soaring on its own, independent trajectory of innovation and invention.

Just how prevalent and dominant CAD/CAM had become is strikingly evident in our September 1985 issue. Almost the entire magazine, it seems, is devoted to manufacturing software: computer-aided design (CAD); computer-aided manufacturing (CAM), which is primarily numerical control programming; material requirements planning (MRP); statistical process control (SPC) and other vital applications. However, the cover story, "A CAD/CAM Checklist," is emblematic.

The content of this article, authored by Paul Olsen of GrafTek, was conveniently summarized on the cover itself. It is apparent that this article was directed to company management (that is, business owners), who were advised to consider how several departments within the company would coordinate or interact via the CAD/CAM system. Workforce skills and training (people) were a factor. Company culture was a consideration. Vendor relationships also were a concern. The author assumed that many readers would be first-time buyers of a CAD/CAM system.

Inside the article, the author raises a number of additional management and technical issues (in a way that seems somewhat superficial and generalized to me today). Several are noteworthy, given the relevance of these same issues in the present. For example, exchangeability and interoperability were just as likely to be barriers in 1985 as they are now.. The Initial Graphics Exchange Specification (IGES), which had been introduced five years earlier, was cited as an important solution, although the fact that IGES was not a perfect or complete solution went unacknowledged. Maintaining a CAD/CAM system with updates and new releases from the developer was mentioned as a discussion point. That is still true 30 years later. The idea of sharing data among applications via a centralized database earns only a few sentences in this article—the details of communication across a network are not discussed (at the time, the internet as we know it today was still about five years away and most shop networks relied on serial ports and RS-232-C capability).

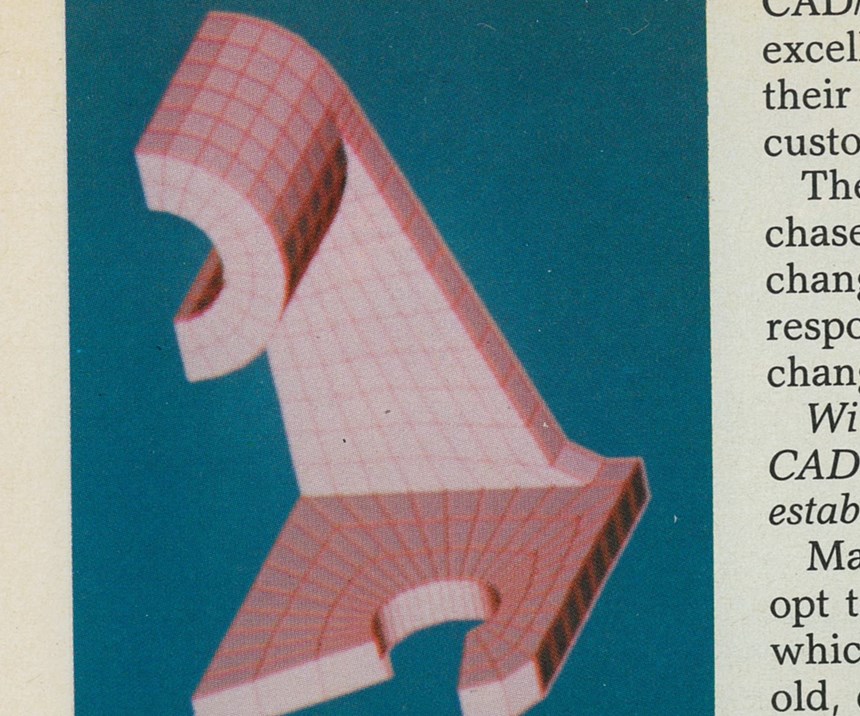

The article gives a glimpse of the state of computer technology in the mid-1980s. For example, it points out that 32-bit processors were displacing 16-bit products. 2D drafting had evolved into 3D wireframes, but solid modeling capability (available and recommended by the author) substantially upped the cost and system requirements, so it prompted this cautionary note: “If the added capability is not needed, don't buy it.”

Browsing the other articles and advertisements in this issue provides a much richer picture of the manufacturing software and hardware landscape of the time. IBM PC, XT and AT personal computers were vying with Apple Macintosh II and IIe models. Digital Equipment Corp., maker of the VAX and PDP-11 “minicomputers,” was also a major hardware supplier, as was Hewlett Packard. PC-DOS, MS-DOS and CP/M were in contention as operating systems. (Microsoft Windows, one of the early graphical user interfaces for PCs, would be released by the end of the year.) The 5-inch floppy disk was giving way to the 3.5-inch diskette (which, oddly, is still the universal icon for the “save” function in today’s software).

For machine shops, punched-paper-tape equipment and time-sharing for automatically programmed tool (APT) processing of NC programs were still around, but fading.

At Modern Machine Shop, editors were working with word-processing systems, and learning the hard way that frequently saving long documents to the disk was very, very important.

Related Content

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreLarge-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More