Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

This video depicts the cable reel system the shop installed to maintain a permanent power connection to the magnetic fixtures supplied by WEN Technology. Mazak, which supplied the V 655-60 VMC with twin 24 × 60-inch pallets seen here, provided an M-code function that enabled switching the magnets on and off via the CNC program. In addition to avoiding the hassle of continually connecting and disconnecting the cables, the ability to demagnetize the fixture in the machine’s interior facilitated chip removal and enabled manual operations such as cleaning and deburring to be performed as part of the machining cycle.

It might be easy to think of productivity problems only in terms of what happens during the cut. However, inefficiencies observed while the machine is running could actually be a result of procedures performed offline — namely, how a job is set up. Improper workholding can be a particular source of lengthy or multiple setups, insufficient rigidity and other issues that can hamper both production and part quality.

One application at a manufacturing facility in Warner Robins, Georgia, provides an example of the benefits that can be gained by choosing the right workholding for the job. This shop, which is one of Cascade Corporation’s seven North American facilities, battled with poor surface finish and less-than-optimal setup and cycle times when attempting to machine a family of steel rails. Switching from hydraulic clamping to a magnetized system from WEN Technology doubled productivity by virtually eliminating setup changes and tool interference issues; increasing the number of parts mounted on each fixture; improving rigidity; and perhaps most importantly, enabling a single operator to run two machines.

A Big Clamping Lift

Cascade Corporation designs and manufactures material-handling equipment and related technologies. Founded in 1943 as a four-man machine shop in Portland, Oregon, the company is now a global operation with subsidiaries located throughout the world. The Warner Robins facility focuses on forklift accessories such as side shifters, fork positioners and load back rests, most of which are machined from steel castings. The shop’s approximately 40 employees work with six CNC machines (two horizontal and four vertical) as well as robotic welding equipment.

The steel rails involved in the troublesome application are components for side shifters, which are attachments for forklift trucks that allow sideways load positioning. Each side shifter includes two rails — one shaped vaguely like an "S" and the other like an "L" — for attachment to the forklift. The shop machines the rails in matched A/B pairs to a wide variety of sizes, though all are long and skinny. Each would fit within a 2-by-3-inch rectangle, and lengths range to 60 inches.

Operations include selective face milling and through-drilling along the length of each rail for mounting and attachment. Initially, the shop used a hydraulic fixture to clamp one A/B pair at a time for machining. Each sat on a locating block while operators oriented the clamps in configurations that would keep the machining area clear.

While this method was relatively effective, it had drawbacks. The clamps typically needed adjustment for almost every different part to accommodate various rail lengths. Additionally, ensuring cutter clearance often required locating clamps some distance from where the actual machining occurred, increasing vibration and deteriorating surface finish. These problems were exacerbated when corporate management decided that every side shifter should be able to accommodate a fork positioner, another attachment that enables the fork itself to shift in and out. Adding the holes and other part features required to mount the fork positioners to the side shifter rails required nearly twice as much machining work.

Consistently Seeing Double With Magnets

To speed rail operations, the shop acquired a new machine: a Mazak V 655-60 VMC with twin 24-by-60-inch pallets. The shop recognized that many of its problems on this job stemmed from setup issues rather than anything inherent to the machining operations, so it also opted to reevaluate its workholding system. Based on significant success at a sister facility, corporate management suggested using magnetic fixtures from WEN Technology with the new machine.

A major difference between mechanical and magnetic clamping is that the former solution pushes the part into a stop, whereas the latter pulls the part onto the magnetic face. In other words, as opposed to the mechanical method of squeezing a part from two sides, a magnetic system generates all clamping force from a single face — the same face that provides the reference positioning. This essential difference would provide a number of improvements for the rail-machining job, as staff manager Ricky Schnable soon discovered.

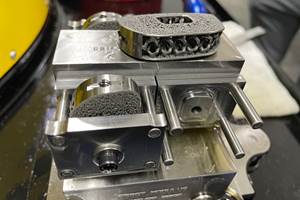

Originally skeptical and a little nervous, Mr. Schnable came on board when he realized that magnetic fixturing would enable each pallet to accommodate two sets of rails at a time (A:A/B:B), as opposed to the hydraulic system that could accommodate only one pair (A/B). That’s because the new workholding method promised to eliminate the requirement to mount clamping mechanisms between parts. This would allow the shop to stack the rails as close together as possible while leaving just enough room for cutting tools to exit one part without running into the next.

Eliminating the clamps also provided other benefits. Operators no longer need to continually reposition clamps from part-to-part to ensure machining access because each rail is mounted atop the magnets, leaving the entire top face open. Moreover, the magnets can run the entire length of the pallet. With an X-reference stop installed at one end, the system can accommodate rails of any length, eliminating the need to change setups for different sizes. Clamping a rail magnetically over its entire length also ensures that all areas are supported equally, reducing vibration and improving surface finish. Finally, without clamps to avoid, the shop can deburr the rails as part of the machining cycle and produce finished pairs in a single fixturing.

To meet required production levels, the shop still uses the old machine with hydraulic fixturing alongside the new Mazak for rail production. When the economy improves, it expects to add magnetic fixtures to that machine as well, Mr. Schnable says. In the meantime, setup time reductions and the elimination of manual operations such as deburring enable the new machine to run with relatively little operator involvement. As a result, a single operator can run both machines, spending the majority of his time on the previous process while the Mazak churns out finished parts. "The cycle time on the new machine is a little bit longer because we’re doing more operations, but overall production has improved," Mr. Schnable says. "The idea was to set it up so that even with slightly longer cycles, the operator wouldn’t have to perform any manual operations between cycles and could keep both machines running continually."

Managing Smarter Magnetization

However, the shop had to overcome a significant hurdle before it could realize the full benefit of these setup time reductions and productivity gains. The problem was the switching of the magnetic circuit; specifically, the fact that the electrical cable had to be disconnected before the pallet could shuttle into the machine. Initially, operators had to repeatedly connect and disconnect the cable from the fixtures, an inconvenient task that added no value to the process. Perhaps more significantly, chips tended to stick to exposed faces of the magnetized fixture — the areas not covered by the part — and resist standard blow-off techniques. Demagnetizing the fixture inside the machine was impossible because the cable had already been disconnected to free the pallet. As a result, all the stray chips were dragged out to the loading station.

To alleviate these problems, WEN provided redesigned electrical boxes, and a permanent connection was installed between the magnet controls and the fixtures using a cable reel system. Once the cable reels were in place, Mazak provided an M-code function that enabled the shop to switch the magnets on and off within the CNC program. Now, the fixture is demagnetized after the machining cycle, and a fan blows stray chips into the machine’s interior before the pallet shuttles out. An auger disposes of the chips, and the pallet moves to the loading station clean and ready for re-use.

Mr. Schnable credits the maintenance department, headed by his brother, Jay, for its dedication in working with WEN Technology to get the fixtures and cabling system up and running. He notes that the "icing on the cake" is the in-cycle chip blow-off. "You load two pairs of rails onto the pallet, and the machine does its thing and delivers two pairs of finished rails that are ready to install on the side shifters," he says.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)