Custom Control Adds Accuracy, Flexibility to New Machine Tool

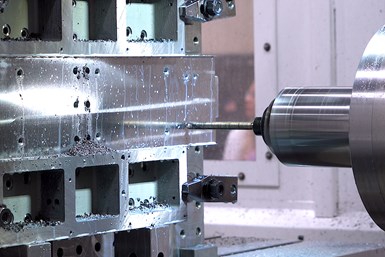

A new boring-mill machine with a custom control is helping a shop hold tighter tolerances and accommodate rapid travel rates for faster machining.

As Lincoln Park Boring expanded into new types of work, including large parts, it needed to make updates to some of its legacy equipment.

Founded in 1956 in the Detroit metro area, Lincoln Park Boring Co. has a rich history in the automotive, machine tool, transportation and energy industries industries. In recent years, the family owned and operated business has begun been replacing older machines with new ones that can handle new production demands and meet customers’ changing needs.

“The key things we’re looking for right now are accuracy, repeatability and ease of maintenance,” says Rick Yesue, president of Lincoln Park Boring. “How long the machine can hold those accuracies without having major rebuilds done, that’s key right now, and also the speeds of feeds and spindle rates.”

As Lincoln Park Boring expanded into new types of work, including large parts, it needed to make updates to some of its legacy equipment.

New Machine, More Accuracy

When the shop was ready to add a new horizontal boring mill, it tapped machine builder Fives Giddings & Lewis to help with the project. “Lincoln Park wanted a machine that could mill all the way through to the center line,” says Micah Mullins, regional sales manager for Fives Giddings & Lewis.

Because Lincoln Park Boring is known for its high-accuracy standards, the new machine was equipped with a high-accuracy package. During the manufacture of the new machine in their Fond du lac, Wisconsin plant, Fives Giddings & Lewis had very strict procedures in place to deliver on the product.

Performance and Flexibility

The machine required robust controls that could deliver the performance needed for the type of work Lincoln Park Boring performs. This led Fives Giddings & Lewis, a FANUC-authorized system integrator, to install a FANUC controller on the machine. Yesue agreed that the FANUC control would be a good fit. “(Fives Giddings & Lewis) have a real trust in FANUC, and that helps us have a trust in FANUC,” he says. “We’ve grown and worked together on a number of things, such as this new horizontal boring mill.”

Lincoln Park Boring wanted a CNC control that had the flexibility to be used manually and could enable quick setups for low part runs. Fives Giddings & Lewis partnered with FANUC to customize the control’s human machine interface (HMI) with a subpanel that has a separate joystick that includes the speeds and feeds. This allows operators to use the machine manually, so they don’t have to program the control to produce one or two parts. “That really helped us to deliver that type of solution,” Mullins says. “And FANUC totally supported us. It was a great partnership.”

The new Fives Giddings & Lewis has more capabilities, can hold tighter tolerances and is able to accommodate more rapid travel rates.

Results

The result is a machine that has more capabilities and can hold tighter tolerances. Additionally, the control is able to run the equipment fast to accommodate rapid travel rates. Yesue says he couldn’t be happier with the end product and believes it will allow the company to go after new business. “FANUC controls are a great control for a boring-mill style machine. It’s a highly capable control and plenty powerful enough for the accuracies needed for this type of work,” Mullins adds.

Additionally, with FANUC offering lifetime support, Lincoln Park Boring won’t have to worry about this control being obsolete in a few years. On top of this, Yesue says his operators don’t have to make a lot of service calls on FANUC products.

“Anything we buy new or retrofit would have a FANUC control,” Yesue says. “Fives Giddings & Lewis and FANUC are where we’re headed in the future.”

Related Content

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreWalter Offers New Solid-Carbide Taps for Blind-Hole Machining

Walter’s TC388 Supreme and TC389 Supreme feature patent-pending cutting geometries that fully shear off the root of the chip when reversing, thus minimizing torque peaks.

Read MoreKay Engineering's Gundrilling Machine Performs Range of Operations

Kay Engineering’s DeHoff 20144 is used to perform gundrilling, pull boring, roller burnishing and thread tapping.

Read MoreNew Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read MoreRead Next

Retrofits Invigorate Old Machine Tools

Retrofitting older machine tools with modern CNC, DRO and linear scales is often cheaper than buying new machines. According to two veteran retrofitters who have worked together for nearly 10 years, such retrofits can often bring outdated machines to like-new condition.

Read MoreCutting Data, Indexable Inserts Optimize Fine Boring

By using digital technology and optimized indexable inserts from Big Kaiser, Schmauser Müller Metalltechnik has increased its process reliability and efficiency in fine boring applications as well as improved tool life.

Read More5G: From the Cloud to the Machine Tool Workzone

Fifth-generation wireless communications standards demonstrate the potential for process control at all levels of a CNC machining business.

Read More

.png;maxWidth=300;quality=90)