New Waterjet Technology Offers Micromachining Alternative

Micro Waterjet LLC offers a machine that overcomes the lack of positioning accuracy and limited cutting stream control that have historically barred waterjet from work at the micro scale.

This year’s International Manufacturing and Technology Show (IMTS) will mark the U.S. commercial debut of a development that could redefine conventional wisdom about the capabilities of waterjet machining. Said to improve positioning and cutting accuracy by a factor of 10 compared with conventional machines, the Micro Waterjet promises to bring the benefits of abrasive waterjet to the micro-machining realm.

Available this fall from Micro Waterjet LLC, the machine offers an alternative method for manufacturing miniature, high-precision 2D components that previously could be produced only via laser or EDM machining—which, like most processes, aren’t necessarily the best fit for all jobs, says Steve Parette, national sales manager. "One of the biggest advantages of waterjet is the lack of heat-affected zones," he explains. "If it’s important to reduce heat, this technology takes EDM and laser out of the competition."

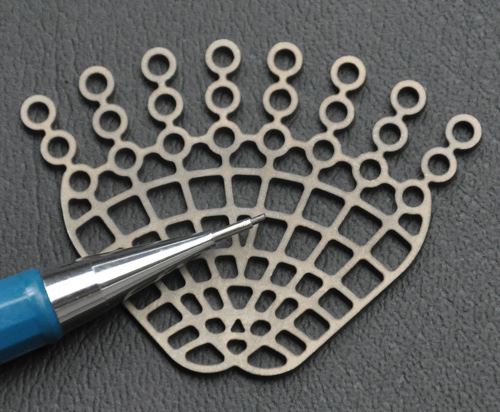

This and other advantages have led increasing numbers of manufacturers to adopt the technique. However, a relative lack of positioning accuracy and limited control of the cutting stream have historically barred waterjet machines from micro work, Mr. Parette says. The Micro Waterjet overcomes these hurdles through proprietary Abrasive Waterjet Micro Machining (AWJMM) technology, which provides positioning accuracy of ±3 microns and cutting accuracy of ±0.01 mm. In addition to custom positioning and workholding systems, the machine’s high precision is attributable to its finer abrasive garnet and a smaller nozzle that produces a kerf width (i.e., cutting stream diameter) of only 0.3 mm, compared to 0.8 mm for most waterjets. It can attain surface finishes as fine as Ra 1.6 µm, depending on material and thickness.

AWJMM is the brainchild of Walter Maurer, owner of Aarwangen, Switzerland-based Waterjet AG. The machines themselves are produced by fellow Swiss manufacturer Max Daetwyler Corporation. The two companies jointly founded Micro Waterjet LLC at Daetwyler’s U.S. facility in Huntersville, North Carolina as a contract manufacturer to feel out U.S. demand for the technology. Since its inception, the company has used Micro Waterjets to machine parts including titanium medical implants; watch components; seals, ventilation grids and complex carbon fiber parts for the motor sports industry; and electronic chip sets, printed circuit boards and sensors.

Most of these parts were previously produced with EDM or laser, not because these processes were the best fit, but rather because the customer simply had no other option. One advantage of waterjet versus EDM is speed. That’s because waterjet can attain the desired surface finish in a single pass, whereas EDM often requires a second. Waterjet can also be a better fit for parts that would otherwise require drilling numerous start holes for threading EDM wire. "If you have a high number of penetrations and small features, you’d have to drill a hole for every one of those and thread the wire through," Mr. Parette explains. "With a waterjet, you simply position the nozzle and start cutting."

Additionally, EDM is limited to only conductive metallic parts, whereas a waterjet can cut virtually any material. Although laser can also cut a variety of substances, the fact that waterjet generates no heat often makes it a better option. Moreover, maintaining accuracy can be more difficult with laser if the work is relatively thick. That’s because the focal point of the beam must be positioned at a very specific area on, above or below the surface to be cut. As the beam progresses through the material, unwanted taper can occur if the focal point isn’t set just right, Mr. Parette says.

That said, EDM is a better fit for material beyond a certain thickness, and laser is typically faster than waterjet for very thin work. Mr. Parette says this demonstrates an important point, one supported by feedback from the company’s customers. That is, each method has its place, and rather than replacing laser and EDM, the Micro Waterjet can complement those processes. For example, moving work that is better suited for the Micro Waterjet away from an EDM or laser can free additional time on that machine for other jobs, and vice versa. The advantage of having high-precision waterjet capability is additional flexibility in selecting the best process for a given part.

After more than a year of success in the contract machining arena, the company plans to import and sell Micro Waterjets to U.S. shops beginning with IMTS 2010. Beyond that, the future is promising for AWJMM, Mr. Parette says. Developments expected to come out of Switzerland in coming years include an even smaller nozzle that will project a stream with a kerf width of 0.2 mm, providing even further capability for precision. Likewise, a rotary axis will enable the machine to accommodate cylindrical parts, such as stents used to prop open arteries.

Related Content

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreWatchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreGrinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)