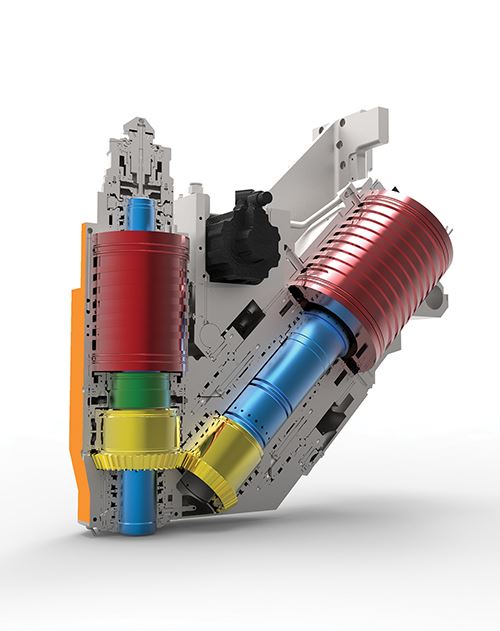

One Spindle Housing, Two Dedicated Spindle Motors

This technology combines two separate and dedicated spindle motors in a single spindle housing—one designed to perform high-torque roughing and the other designed for high-speed finishing.

Shops have options if they want a machine with the flexibility to perform both roughing and fine-finishing operations. For instance, there are gearbox designs that enable a machine to run at low rpm with high torque for roughing or at higher spindle speeds for light finishing cuts. In addition, auxiliary high-speed spindles can be installed into the main spindle of a high-torque machine to enable it to perform finishing work, too.

There are downsides to both of these options, however, says Bob Pruden, president of Cincinnati, Ohio’s Pilsen Imports. Auxiliary spindles installed in a machine’s main spindle reduce the total available Z-axis travel, he says. And while a gearbox machine can operate in low-speed/high-torque mode or at higher spindle speeds, the shared spindle bearing system isn’t optimized for either.

Mr. Pruden says this is why the patented Double-Drive Technology (DDT) spindle design available from Swiss machine tool builder Reiden Technik is a better choice. (His company recently became the exclusive importer of Reiden machine tools in the United States.) DDT is a spindle option for Reiden’s RX series of universal five-axis machines that are available in RX10, RX14 and RX18 models. The technology combines two separate and dedicated spindle motors in a single spindle housing—one designed to perform high-torque roughing and the other designed for high-speed finishing. Unlike gearbox designs, each separate spindle motor uses components such as bearings that are tailored specifically to the spindle motor’s operating range.

A hydraulic circuit is used to engage the angled high-torque spindle motor via a bevel gear coupling while the high-speed spindle motor freewheels. When the hydraulic circuit is off, the bevel gear on the high-torque spindle motor retracts to enable the high-speed spindle to be used.

The machine’s CNC automatically chooses the spindle motor to be used based on the spindle speed called for in the part program (no special programming is required). For example, the RX10 model with DDT uses its 36.6-horsepower, 214.6-foot-pound high-torque spindle motor at spindle speeds of 3,000 rpm or lower. For spindle speeds higher than that (ranging to 16,000 rpm), it uses its high-speed spindle motor providing 37.5 horsepower and 61.2 foot-pounds of torque. (These values differ for the larger RX14 and RX18 models, which feature trigonal/nutating heads.) The RX10 model with DDT uses an HSK63 spindle interface while the RX14 and RX18 models with DDT use an HSK 100 spindle interface.

The DDT technology is well-suited for die/mold applications as well as machining of titanium aerospace components that requires high torque for maximum material removal and high speed for drilling small holes, for example. It enables the RX series machines to produce a variety of components in a range of different materials, including aluminum, steels, cast iron and high-temp alloys, making it well-suited for job shop work. It also helps ensure feature-to-feature accuracy because both roughing and finishing operations can be performed in one setup on one machine. According to Reiden, there are approximately 60 RX series machines with the DDT high-speed/high-torque spindle option installed in Europe and Asia.

Related Content

Choosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More.jpg;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)